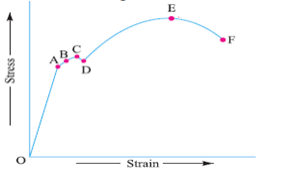

Explain with neat sketch the stress-strain diagram for ductile material.

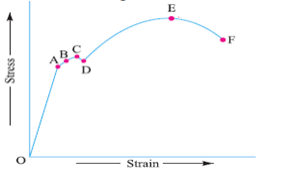

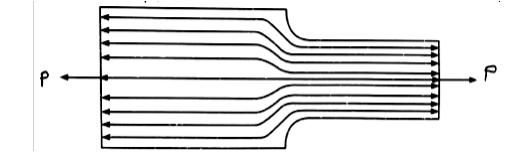

Stress Concentration: Whenever a machine component changes the shape of its cross-section, the simple stress distribution no longer holds good and the neighborhood of the discontinuity is different. This irregularity in the stress distribution caused by abrupt changes of form is called stress concentration. It occurs for all kinds of stresses in the presence of fillets, notches, holes, keyways, splines, surface roughness or scratches etc.

1. Recognition of need. First of all, make a complete statement of the problem, indicating the need, aim or purpose for which the machine is to be designed. 2. Synthesis (Mechanisms). Select the possible mechanism or group of mechanisms which will give the desired motion. 3. Analysis of forces. Find the forces acting on each member of the machine and the energy transmitted by each member. 4. Material selection. Select the material best suited for each member of the machine. 5. Design of elements (Size and Stresses).

1) The shape should not be like blocks but various forms like sculpture, streamlined, aerodynamic, taper should be used. 2) The component should be symmetrical at lean about one axis. 3)proper shape of a product help to make the product more attractive. 4) The shape of the product should be regular, even & proportionate Regarding Colour: ……….Any 2 pt : 1 M Each 1) The colour and shape of component should be such that in should attract appeal and impress customer. 2) The colour should match with conventions, moods e.g.

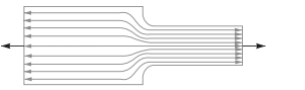

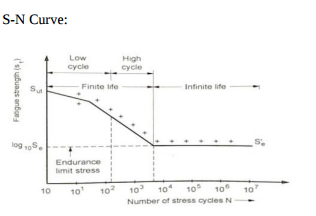

Endurance Limit: It is defined as maximum value of the completely reversed bending stress which a polished standard specimen can withstand without failure, for infinite number of cycles (usually 107 cycles).It is known as endurance or fatigue limit (ϭe).

i. It saves effort of design of engineers to design and manufacture new machines, as standard components are readily designed by experts. ii. It ensures certain minimum specified quality. iii. It help in manufacturing the components on mass production. iv. Easy and quick replacement of the components is possible. v. Interchangeability of components is possible. vi. It helps in manufacturing the components quickly and economically. vii. Effective utilization of resources. viii. It also contributes to ensure the safety

a. Reliability of applied load. b. The extent of simplifying assumptions. c. The certainty as to exact mode of failure. d. Reliability of properties of material and change in these properties during service. e. Extent of stress concentration. f. The reliability of test results to actual machine parts. g. The extent of initial stresses set up during manufacturing. h. The extent of loss of life, if failure occurs.

i. Stress Concentration: Whenever a machine component changes the shape of its cross-section, the simple stress distribution no longer holds good and the neighborhood of the discontinuity is different. This irregularity in the stress distribution caused by abrupt changes of form is called stress concentration. It occurs for all kinds of stresses in the presence of fillets, notches, holes, keyways, splines, surface roughness or scratches etc.

Stress-Strain diagram for ductile material stating salient points (1 Mark for diagram, 3 Marks for description)

.

Proportional limit (A): The stress is proportional to strain. Beyond point A, the curve slightly deviates from the straight line. It is thus obvious, that Hooke's law holds good up to point A and it is known as Proportional limit.

Endurance Limit: It is defined as maximum value of the completely reversed bending stress which a polished standard specimen can withstand without failure, for infinite number of cycles (usually 107 cycles).It is known as endurance or fatigue limit (ϭe). Need of Endurance Limit in Machine Design: Endurance limit is used to describe a property of materials: the amplitude (or range) of cyclic stress that can be applied to the material without causing fatigue failure.