Draw the constructional details diagram of centrifugal clutch.

Explain its working principle

Draw the constructional details diagram of Centrifugal clutch. Explain its working principle.

Working Principle of Centrifugal Clutch:

The centrifugal clutch uses centrifugal force, instead of spring force for keeping it in engaged

position. Also, it does not require clutch pedal for operating the clutch. The clutch is operated

automatically depending upon the engine speed. The vehicle can be stopped in gear without

stalling the engine. Similarly the vehicle can be started in any gear by pressing the accelerator

pedal. This makes the driving operation very easy.

OR

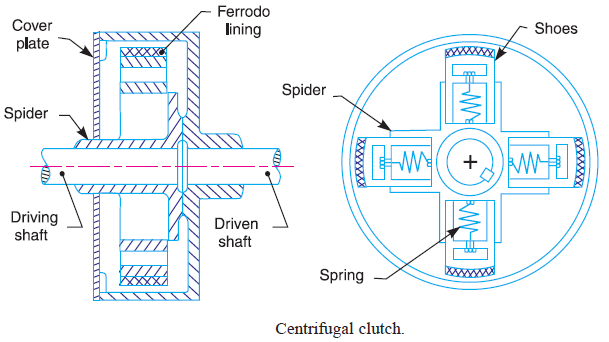

The centrifugal clutches are usually incorporated into the motor pulleys. It consists of

a number of shoes on the inside of a rim of the pulley, as shown in Fig. The outer

surface of the shoes is covered with a friction material. These shoes, which can move

radially in guides, are held against the boss (or spider) on the driving shaft by means of

springs. The springs exert a radially inward force which is assumed constant. The mass

of the shoe, when revolving, causes it to exert a radially outward force (i.e. centrifugal

force). The magnitude of this centrifugal force depends upon the speed at which the

shoe is revolving. A little consideration will show that when the centrifugal force is less

than the spring force, the shoe remains in the same position as when the driving shaft

was stationary, but when the centrifugal force is equal to the spring force, the shoe is

just floating. When the centrifugal force exceeds the spring force, the shoe moves

outward and comes into contact with the driven member and presses against it. The

force with which the shoe presses against the driven member is the difference of the

centrifugal force and the spring force. The increase of speed causes the shoe to press

harder and enables more torque to be transmitted.

marks:

- Log in to post comments