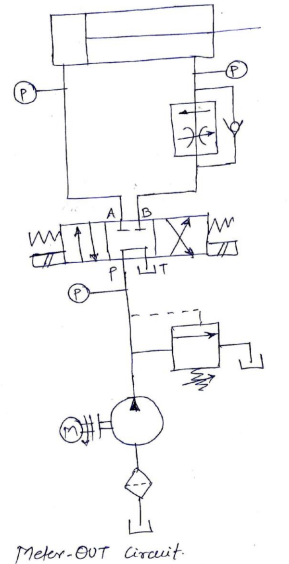

Explain with neat sketch the working of meter out hydraulic circuit.

Meter OUT Circuit A typical meter out circuit is shown in figure. Here the flow control valve is installed in the return line metering the fluid being discharged. In that way, this circuit also gives the control over the actuating speed. But this way of control offers altogether different characteristics to the circuit. Now, the circuit pressure has to overcome the load resistance and the pressure drop across the flow control valve. However, as the flow control valve is on the right side of the piston, the differential area will cause rise in the pressure. This increased pressure helps to overcome the pressure drop across the flow control valve. As the system pressure required will be relatively low, it makes this circuit marginally more efficient on the extend stroke. Initially, the compensatory spool is fully open, and full pump flow is passed into the cylinder until piston moves forward building up pressure at the flow control valve. The compensatory spool will now come into operation and restricts the flow to its correct value. Thus, there is an initial flow surge before the compensatory spool adjusts as in the case of ‘meter-in’ When using meter-out system, the pressure in the rod-end of the cylinder must be carefully considered. With meter-out speed control, the quantity of oil leaving the cylinder is controlled. When the cylinder is extending, the oil from the rod-end is metered which a smaller quantity than that is flowing into the full bore end. Consequently, under extend conditions; meter-out flow control is not as sensitive as meter-in control. When the cylinder is retracting, the reverse is true. Meter-out circuits are best where negative loads may occur, because back pressure is maintained on the exhaust side of the actuator preventing erratic motion. Meter-out circuits provide accurate speed control even with reversing loads. However, as with the meter-in system, considerable heat will be generated when used with a fixed delivery pump and a wide range of piston speeds. Applications: Drilling, Boring, Reaming and tapping operations.