A helical valve spring is to be designed for an operating load range of approximately 135 N. The deflection of the spring for the load range is 7.5 mm. Assume spring index of 10. Permissible shear stress for the material of the spring = 480 MPa and its mo

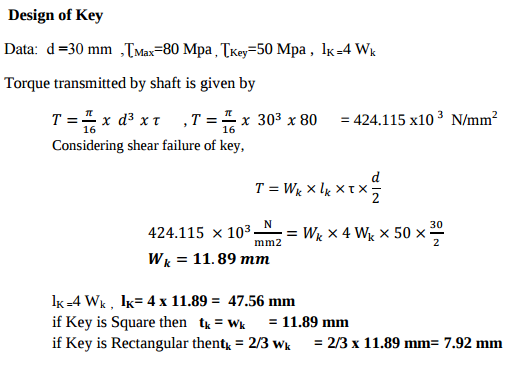

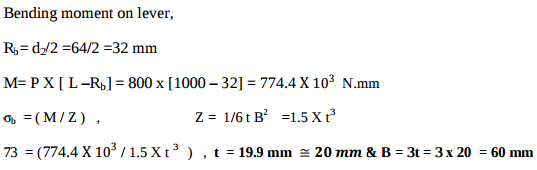

given load W= 135N Deflection ᵟ =7.5mm Spring index c=10 Permissible shear stress Ʈ=480 MPa Modulus of rigidity G =80 KN/mm2 Wahl’s factor K =4C-1/4C-4 +0.615/C=4X10-1/4X10-4 +0.615/10=1.14 (1)Mean dia. Of the spring coil (1 mark) Maximum shear stress, Ʈ = Kx 8WC/π d 2 480 = 1.14x 8x135x10/3.142xd2 d = 2.857mm from table we shall take a standard wire of size SWG 3 having diameters (d) =2.946mm mean dia. Of the spring coil D= CXd =10x2.946=29.46 mm outer dia.