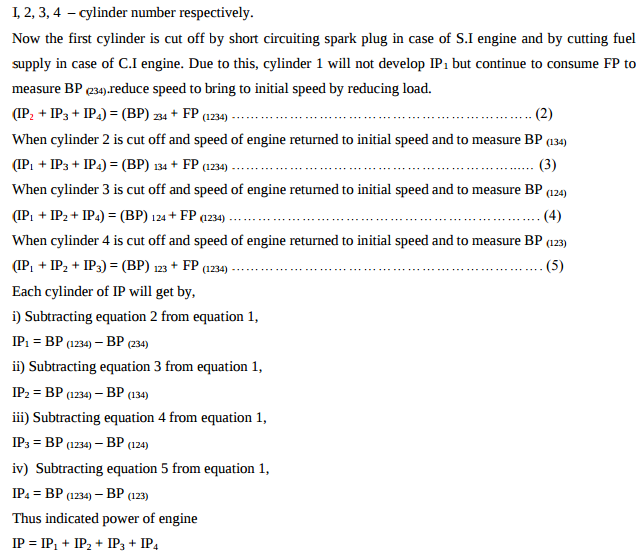

Explain in brief, how ‘Morse test’ is carried out ?

First engine is allowed to run at constant speed and brake power of engine is measured when all four cylinder working. (IP1 + IP2 + IP3 + IP4) = (BP) 1234 + (FP) 1234 Where, IP- indicated power. BP – brake power develop. FP – frictional power.