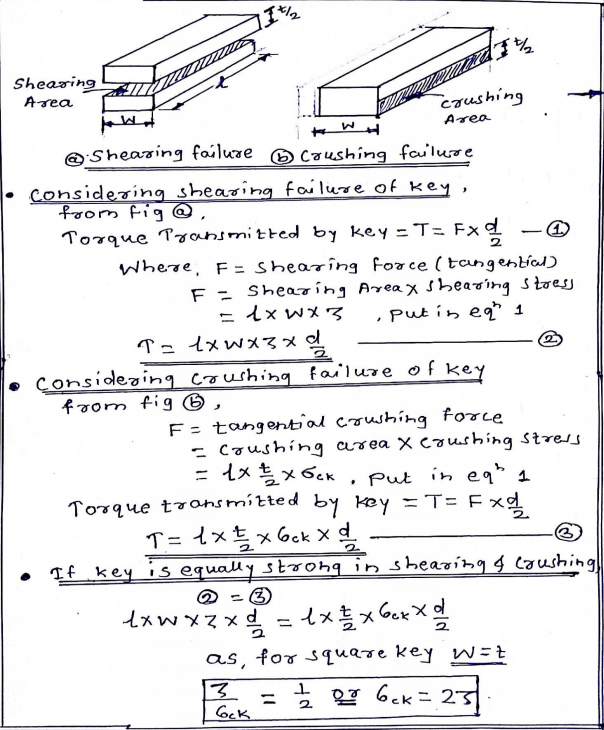

Prove that, for a square key, the permissible crushing stress is twice the permissible shear stress.

i. It saves effort of design of engineers to design and manufacture new machines, as standard components are readily designed by experts. ii. It ensures certain minimum specified quality. iii. It help in manufacturing the components on mass production. iv. Easy and quick replacement of the components is possible. v. Interchangeability of components is possible. vi. It helps in manufacturing the components quickly and economically. vii. Effective utilization of resources. viii. It also contributes to ensure the safety

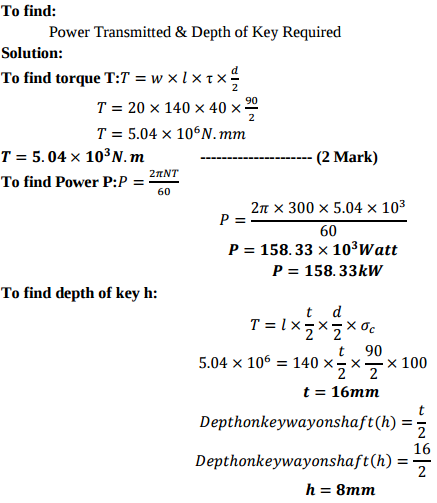

It consist of 3 elements i. Socket ii. Spigot iii. Cotter Where, d= End diameter of rodd1= Diameter of spigot/ID of socket d2= Diameter of spigot collar D1= Outer diameter of socket D2= Diameter of socket collar C=Thickness of socket collar t1= Thickness of spigot collar t= thickness of cotter b= Mean width of cotter a= Distance of end of slot to the end of spigot P= Axial tensile/compressive force σt, σc, τ= Permissible tensile, compressive, shear stress for the component material

a. When cotter is driven through the slots, it fit, fight due to wedge action. This ensures tightness of joint in operation and present loosening of the parts. b. Due to taper, it is easy to remove the cotter and dismantle the joint. The normal value of taper varies from 1 in 48 to 01 in 24 and it may increase to 1 in 8

a. Reliability of applied load. b. The extent of simplifying assumptions. c. The certainty as to exact mode of failure. d. Reliability of properties of material and change in these properties during service. e. Extent of stress concentration. f. The reliability of test results to actual machine parts. g. The extent of initial stresses set up during manufacturing. h. The extent of loss of life, if failure occurs.

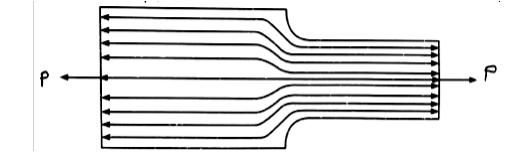

i. Stress Concentration: Whenever a machine component changes the shape of its cross-section, the simple stress distribution no longer holds good and the neighborhood of the discontinuity is different. This irregularity in the stress distribution caused by abrupt changes of form is called stress concentration. It occurs for all kinds of stresses in the presence of fillets, notches, holes, keyways, splines, surface roughness or scratches etc.

. Square threads are preferred over V-thread for power transmission because of following points. 1) Square thread has the greatest efficiency as its profile angle is zero. 2) It produces minimum bursting pressure on the nut. 3) It has more transmission efficiency due to less friction. 4) It transmits power without any side thrust in either direction. 5) It is more smooth and noiseless operation.