Explain different forms of threads with their relative advantages and applications.

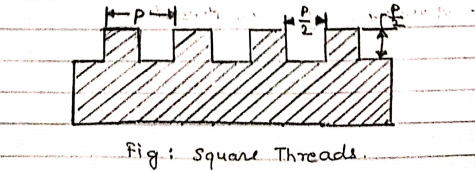

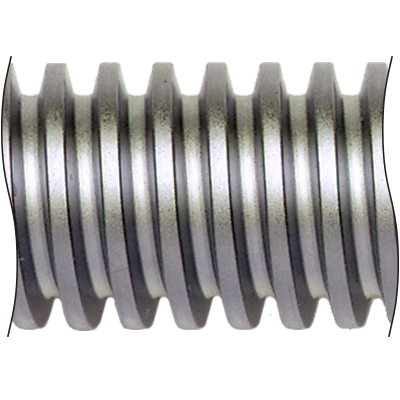

Square threads

Square threads are the most commonly used thread form for the power screws. Following table gives you various thread forms and comparisons.

|

Screw Form |

Characteristic |

Application |

|

Sq. Thread

|

No side thrust Higher efficiency |

Used for general purpose power transmission |

|

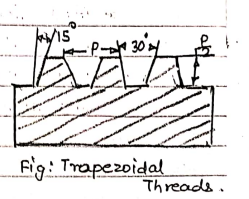

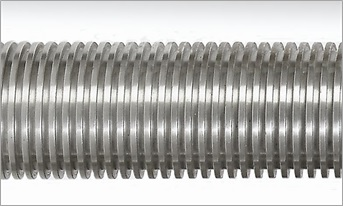

Trapezoidal Threads |

Stronger than square threads Easy to manufacture Wear compensation |

Used for higher power transmission |

|

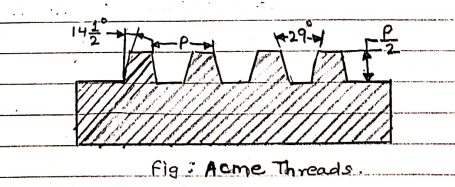

ACME threads |

Stronger than square threads Easy to manufacture Wear compensation |

Used for higher power transmission |

|

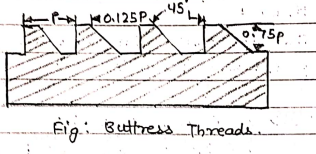

Buttress threads |

Can bear very heavy load in one direction |

Used to handle heavy forces in one direction, like in truck jack |

Sq. threads Advantages and disadvantages

The advantages of sq. threads are as follows:

1) Efficiency of sq. threads is more than trapezoidal threads

2) There is no side thrust or radial pressure.

The disadvantages of sq. threads are,

1) Sq. threads are difficult to manufacture than trapezoidal threads.

2) The wear of sq. threads can not be compensated as it can be done in trapezoidal.

3) The thread thickness at core is less than trapezoidal, hence sq. threads have less load carrying capacity.

Square threads and other forms diagrams

Sq. threads are preffered over v threads why?

Sq. threads are preferred in power transmission over v threads because fo the following reasons,

1) Sq. threads have maximum efficiency in power transmission

2) Sq. threads have noiseless operation.

3) Sq. threads have no side thrust.

So these advantages are the main requirements of application of square threads in power transmission. Hence sq. threads are preferred over v or trapezoidal threads.

Comparison of square threads and v threads

|

Point |

Sq. threads |

Trapezoidal threads |

|

Efficiency |

More |

Less |

|

Side thrust |

No |

Yes |

|

Manufacturing |

Difficult {single point tool} |

Easy {Multi Point tool} |

|

Strength |

Less {less area at root} |

More {more area at root} |

|

Wear |

Can not be compensated |

Can be compensated |

Links to other units of the subject Machine design