Key Points to Remember

- Belt transmission is comparatively simple, trouble free, easy to be serviced ,maintained and have relatively low initial cost.

- Belts can connect non-parallel shafts also.

- Belts do not have space constrain, lubrication or heating issues.

- Since belts are flexible matreial there is inbuit shock protection.

- Mainly belt drives are Flat belt drive and V- belt drive

- Flat belts although simple and economical they have relatively less grip and make more noise.

- Flat belt are made up of from leather or fabric rubber.

- V belts are made from polyster fabric and cords which carry the load. And outer cover of V belt is made from polychloroprene impregnated.

- Belt drives are found wide in applications ranging from machine tools to automoiles.

- Flat belts are commercially available as rolls, from which required length is cut, whereas V belts are manufactured in standad section sizes and lengths.

Questions and Answers :

Q.1) Why belts are called 'Flexible'Drives ? What advantages and limitations they offer over the gears ?

Ans : In belt drives there is no direct contact between the driving and driven member, but the connection is through a flexible link called Belt, Hence this drive is name as Flexible drive. The belt can absorb the shock and also permits the misalignment due to its flexibility.

Following are the advangtanges it offers over the gear drive.

- Belt drives can transmit power over a long distance which is not feasible with gears.

- Since the intermediate link is long and flexible it can absorb the shocks and vibrations

- Due to flexibility there is no space and tolerance constrains like gears.

- Belt drives are very cheaper as compared to the gear drives.

- Belt drives are simple to design.

Following are the limitations of belt drives over gear drives.

- There are chances of slip in belts,hence belt drives are not positive drives and not 100% reliable.

- They cause more noise than gears.

- Belt drives occupy more space as compared to gear trains

- Large velocity ratio can not be obtained with belt drives as compared to gear trains.

Q.2) Compare Flat Belt and V belt drive ?

Ans : Following table provides the comparison

| Flat belt drive | V belt drive |

|---|---|

| Simple and economical | Complex and costly |

| Suitable for low speed and long distance power transmission | Suitable for high speed and small distance power transmission |

| Adaptable to parallel,skew,intersecting shafts | Adaptable for parallel shaft only |

| Pulley needs crowning |

Pulley nees v groove cut in it |

| Less efficiency due to chances of slip | More efficient due to very less change of slip |

| Adjustment of length is possible by cutting the flat belt | Adjustment of length is not possible as the belts are availabe in standard lengths |

| Less frictional grip on pulley | More frictiona grip on pulley due to wedging action of belt in V groove |

| More angle of contact is required to have more grip | Less angle of contact is permissible due to wedging action of the belt |

| Suitable of low velocity ratio | Suitable for higher velocity ratio |

| Needs more space due to width of belt | Needs less space due to small width belt |

| Used in machine tools, flour mills, belt conveyors etc | Used in automobiles, textile machinary, saw mills, bucket elevators. |

Q.3) State the advantages and disadvantages of Flat belt over V-belts?

Ans : Advantages of Flat belt over V- belt,

- Flat belts are relatively cheap and simple in construction

- Flat belts can can be used for long central distances

- Different velocity ratios can be obtained with stepped pulleys

- Flat belts are adaptable to paralle,skew and intersecting shafts.

- Easy to replace or adjust length.

- Do not require special pulley.

Disadvantages of Flat belt over V belt

- The power transmission capacity is low

- Less frictional grip which results in chances of slippage

- Make more noise.

- Can not be used for very high velocity ratio.

- Need more space due to width of belt as compared to v for same power transmission

- More angle of contact is required as compared to v belts.

Q.4) State the advantages and disadvantages of V belt over Flat belts?

Following are the advantages of V belt over flat belts

- More frictional grip due to wedging action of belt on pulley.

- Compact in construction

- Slip is very negligible due to wedge action.

- Noiseless operation

- Higher velocity ratio is possble

Following are the limitations of V belt over flat belt

- Complex and costly

- Can not be used for very large distance power transmission

- It is adaptable to parallel shafts only.

- V belts have higher creep than flat belts.

Q.5) State the procedure for selecting Flat belt from manufacturers catalogue?

Steps for selection of Flat belts from Manufacturer's catalogue

Refer the Problems section below

Q.5) State the procedure for selecting V belt from manufacturers catalogue?

Steps for selection of V belts from Manufacturer's catalogue

Refer the Problems section below

Selection of flat belts Numerical problems

- Flat belts are mostly made up of leather, which are obtained by tanning the skin of animals. It has one flesh side and other hair side. Generally hair side is kept in contact with the pulley for better grip.

- Flat belts are also mde from fabric and rubber. These are made drom several layers of canvas or cotton duck impregnated with rubber.

- Flat belts are available as free length rolls, these are cut and joined to required length, they are joined by laced joint or wire clips.

- Flat belts may be connected as open belt or crossed belt, in open belt both driving and driven pulleys rotate in same direction, whereas in crossed belt both rotate in reversed direction.

- Flat belts are suitable for moderate power transmission when the distance between two shafts is large.

- Flat belts make more noise as compared to V belts.

Steps for selection of Flat belts from Manufacturer's catalogue

- Select optimum belt velocity between 17 to 22 m per second. based on this optimum velocity calculate the diameter of smaller pulley and then calculate the diameter of bigger pulley using speed diameter ratio.

- determine the load correction factor from manufacturers table it is denoted by fa.

- calculate the angle of wrap for the smaller pulley using the standard relation,then find the arc of contact factor Fd.

- calculate the corrected power by using relationship

- calculate the corrected power rating for the belt, now here you have to choose between high speed belt and fort Belt.

- calculate the product of width X number of price by dividing the corrected power buy corrected kW rating. further in this type we determine the belt width by asuming suitable number of plies

- calculate the final length of belt using the standard relation.

Numerical problems of Flat belt

- An open belt drive is required to transmit 25 KW, from a motor which is running at 1440 RPM. the motor drivers the pump which is running at 720 RPM. select the flat belt from manufacturer catalogue to suit this requirement, the space available for Central distance of 3 metres.

- A motor running at 1440 RPM is transmitter 10 kilowatt to another machine running at 360 RPM. the two pulleys are to be connected by flat belt drive which is open type and the space is limited 22 metres approximately. select the flat belt from the manufacturer's catalogue data provided.

- it is required to select a flat belt drive to run an air compressor running at 400 RPM, the driving motor Trance mix 30 kilowatt at 1440 RPM, if the space constraint is approximately 3 metres and the belt drive is open type select the suitable belt from the data provided by manufacturers catalogue.

- it is required to select a flat belt drive transmitting power from a motor running at 1440 RPM while transmitting a power of 15 kilowatt, the motor drives a centrifugal pump which is running at 350 RPM, if the space constraint is about 1 m Centre to Central distance select the suitable flat belt taking into account load correction factor as 1.3, the belt velocity between 18 to 23 m/s, ARC of contact 180 degrees.

Selection of VEE belt problems

IMPORTANT POINTS TO REMEMBER

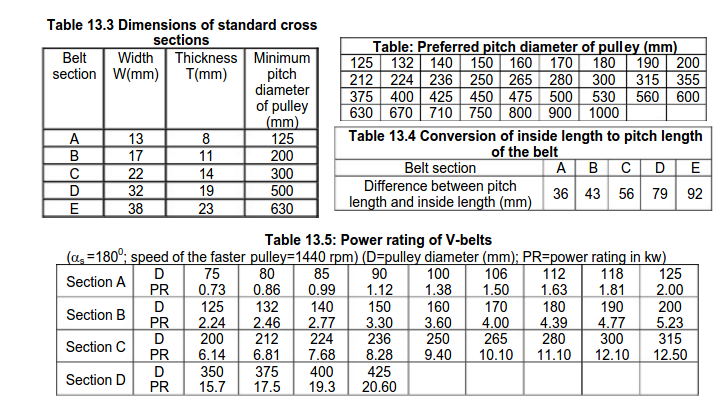

- Designer is required to select the V belt from the catalogue provided by the manufacturer, for this purpose he needs the information such as 1) Type of driving unit 2) Type of driven unit 3) Power to be transmitted 4) Input and Output speeds 5) Operation in hours per day 6) Space availability in terms of centre to centre distance

- Designer should follow the following steps to reach the final selection

- Determine the Correction factor Fa from table depending upon the driving unit, driven unit and operational hours.

- Calculate the Design power by Multiplying the given power by Fa

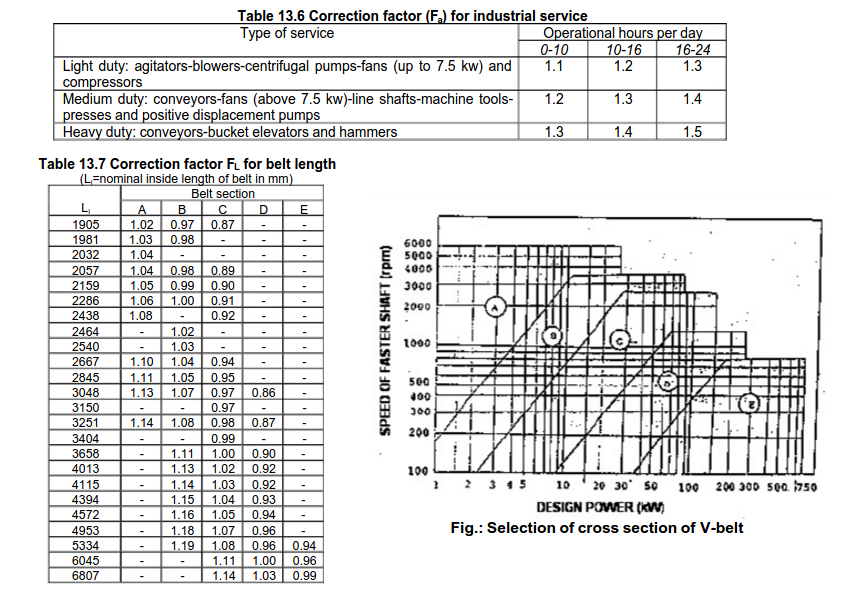

- On cross section selection chart plot a point with design power as x-coordinate and input speed as y-coordinate and select the crosssection as A,B,C,D or E.

- Determine pitch diamter of the smaller pully from table, depending upon the cross section of the belt. Then decide the bigger pulley diamter by using speed diameter relation

- Determine the pitch length of the belt by using standard relation.

- Compare the Length value obtained from calculation in step 5, to the nearest standard value from the table provided by manufacturer.

- Find the new correct value of central distance C by using the actual standard length.

- Determine the correction factor Fc for belt pitch length from table, it depends upton the type of cross-section and pitch length of the belt.

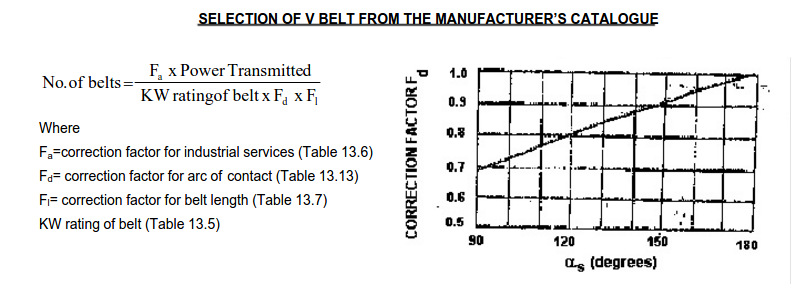

- Calculate the arc of contact for smaller pulley using standard relation.

- Determine power rating of single belt, which depends upto speed of shaft(faster of both), pitch diameter of smaller pulley and speed ratio.

- Determine the number of belts required to fulfil the required design power using formula,

Numerical Problems on selection of V-belts

- A compressor is to run at 250 r.p.m. and requires 90 kW. The drive is provided by V belts from an electric motor running at 750 r.p.m. the diameter of the pulley on the compressor shaft is restricted to 1 meter whereas the centre distance between the pulleys is limited to 1.75 meter. The belt speed should not exceed 1600m/min. Determine the number of V belts required to transmit the power if each belt has a cross sectional area of 375 mm 2 , density 1000 kg/m 3 and an allowable tensile stress of 2.5 MPa. The groove angle of the pulley is 35°. The coefficient of friction between the belt and the pulley is 0.25. Also calculate the length of each belt.

- It is required to design a V belt to connect a motor running at 1440 rpm and transmitting power of 7.5 kW, to another machine running at 500 rpm. The operation is likely to be running 24 hours of day. The space limitation is about 1 m in length.

- Select a V-belt from manufacturers catalogue required to transmitter power of 15000 watts running at 2880 RPM. it is estimated that the belt will run for 18 hours per day. the central distance should not exceed 400 mm. assume that pitch diameter of driving Pulley is 125 mm.

- it is required to select a v belt from manufacturers catalogue which should transmit 5 kilowatt power while running at 1440 RPM,it delivers power to a device which is running at 1000 RPM. assuming that the device runs for 24 hours per day and the space available for a central distance of about 0.5 m. take the diameter of driving Pulley has 150 mm.

- it is required to select a v belt drive transmitter power of 20 kilowatt running at 1400 50 RPM to a compressor which is running at 480 RPM.it is estimated that the compressor will run for about 15 hours per day and the space available for a central distance of approximately 1.2 metres. determine number 1) specifications of belt 2) diameters of motor and compressor pulley 3) the correct Central distance 4 the number of belts required.

- A v belt drive is rquired to transmit 17.5 kW running at 1440 rpm motor. The motor drives a pump which runs at 400 rpm. Assuming that pump runs for about 8 hours per day and space limitations about 1 m. Determine 1) Belt specification 2) Number of belts 3) Correct centre distance and 4) Pulley diameters

CHARTS FOR V BELT SELECTION

Objective type Questions and Answers on Belt drives

Links to other Topics in Machine design I

Machine Design I - Introduction to Design : Theory Q&A

Machine Design -I -Design of joints : Theory Q&A

Knuckle Joint : Design Procedure,Problems and Questions

Cotter Joint : Design Procedure,Problems and Question answer

Design of turnbuckle : Design steps, Problems and Question

Design of Levers : Hand Lever, Foot Lever, Bell crank lever

Design Of Bolted and Welded Joints

Design of Shafts: Theory and Numerical Problems

Couplings : Design Procedure and Numerical problems

Design Of SPRINGS : Questions and Numerical problems

Power Screw Design

- Log in to post comments