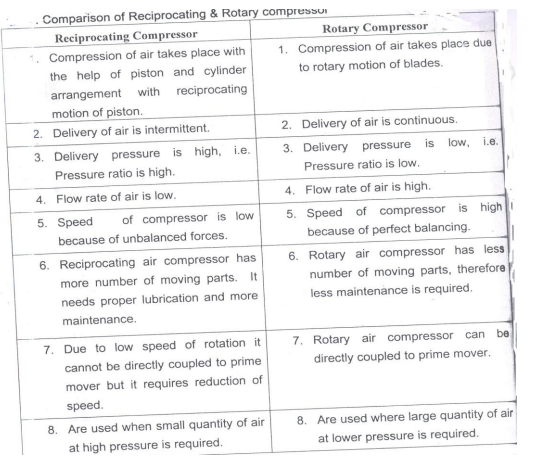

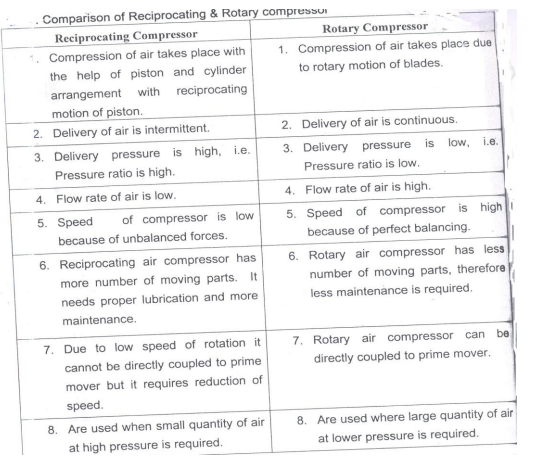

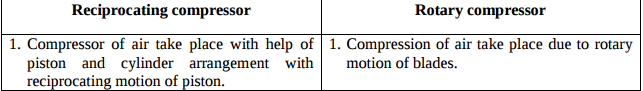

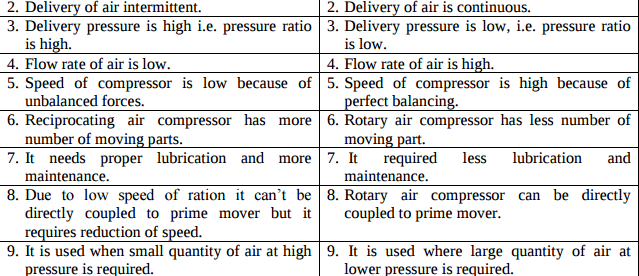

Differentiate between reciprocating air compressor and rotary air compressor.

1. The air can be cooled in between two cylinders 2. The power required is less 3. Mechanical balance is good 4. Reduced leakage losses 5. More volumetric efficiency 6. High pressure range 7. Comparatively lighter in construction

Following are the applications of compressed air 1) To drive air motors in coal mines. 2) To inject fuel in air injection diesel engines. 3) To operate pneumatic drills, hammers, hoists, sand blasters. 4) For cleaning purposes. 5) To cool large buildings. 6) In the processing of food and farm maintenance. 7) In vehicle to operate air brake. 8) For spray painting in paint industry.

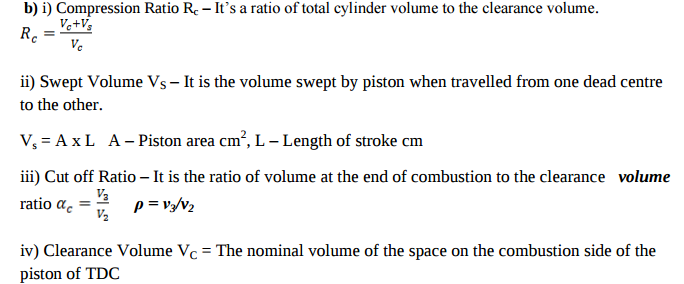

Define i) Free air delivered (FAD) – It is volume of air delivered under the condition of temperature and pressure existing at compressor intake, i.e. volume of air delivered at surrounding air temperature & pressure. In absence of any given free air conditions these are generally taken as 1.101325 bar and 150 c. ii) Compressor capacity – It is quantity of free air actually delivered by compressor in m3 /min. iii) Swept volume – It is the volume of air taken during sanction stroke. It is expressed in m3 . iv) Pressure ratio – It is defined as delivery pressure to suction pressure.

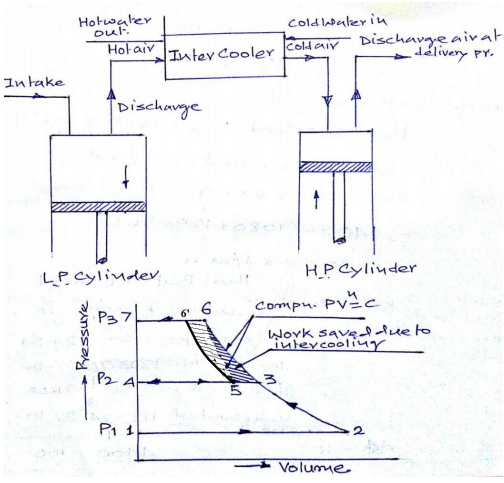

Necessity of multistage compression i) As index of compression ‘n’ increases it increases compression work. ii) Increase in pressure ratio (P2/P1) it increases work as well as size of cylinder. iii) Increment in pressure ratio (P2/P1) beyond certain limit, volumetric efficiency decreases while it increases leakage loss on either sides the piston and valves. Due to above pointes and for higher pressure ratio compressor needs multistaging.

Uses of compressed air:- 1. Cleaning automobiles 2. Pneumatic tools 3. Supercharging in I.C. engines 4. Cooling of large building 5. Construction of bridges, roads etc. 6. Spraying points 7. Spraying fuel in high speed diesel engine 8. Starting of I.C. engines

Multi-stage air compressors feature many benefits and so, they are mostly used in the market. Some of those features are given below 1. Higher air pressures are achievable by multi-staging (about 175 PSI against 120 PSI in single stage) 2. It requires less power for running 3. Light weight cylinders can are used 4. Leakages are less 5. Overall discharge temperatures are lower 6. Intercooler increases the efficiency of unit 7. It has a greater durability 8. Many multi-stage air compressors have the crankcase cast separate from the pump cylinders, which makes it easier to repair. 9.