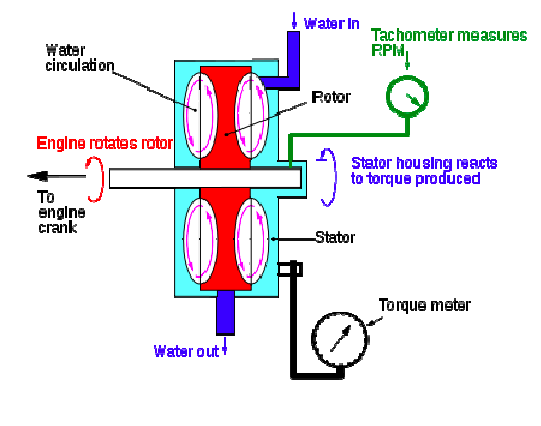

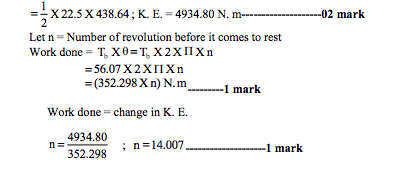

Explain with neat sketch construction and working of eddy current dynamometer.

Eddy Current Dynamometer : It consists of a stator on which are fitted a number of electromagnets and a rotor disc made of copper or steel and coupled to the output shaft of the engine. When the rotor rotates, eddy currents are produced in the stator due to magnetic flux set up by the passage of field current in the electromagnets. These eddy currents oppose the motion of the rotor thus loading the engine. The eddy currents are dissipated in producing heat so that this type of dynamometer also requires some cooling arrangements.