KEY POINTS TO REMEMBER

- A cylinder is said to be 'THIN' if the ratio of its inner diameter to the thickness of wall is more than 20. And when it below 20 then it is termed as thick cylinder.

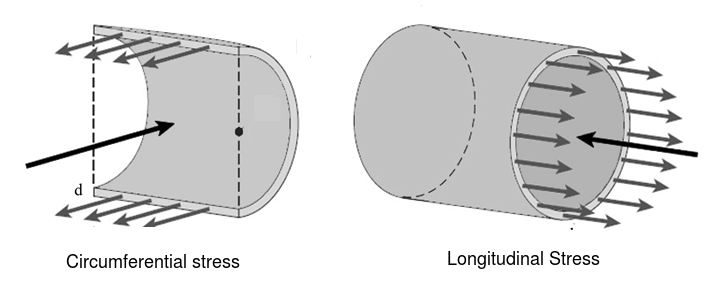

- A thin cylinder is subjected to two principal stresses, Circumferential stresses (along circumference) and longitudinal stress (along length).

- For thin cylinders circumferential stress is twice the longitudinal stress.

- In thick cylinders, it is assumed that the tangential stress is uniformly distributed over cylinder wall thickness, whereas the tangential stress has highest value at inner surface and gradually decreases towards the outer surface.

- The radial stress is negligible in thin cylinders but has considerable magnitude in thick cylinders.

- Lame's equation is based on maximum principal stress theory of failure, and is used when the material of cylinder is brittle.

- Clavarino's and Birnies equations are based upon maximum strain theory of failure, and is used when the material is ductile.

- A compound cylinder is made up of two cylinders which are fitted on each other by shrinkage technique, the outer is called Jacket and inner is called simply cylinder.

- Autofrettage is a process of prestressing the cylinder before it is actually put into service. It is done to increase the pressure capacity of cylinders.

Theory Questions and Answers :

Q.1) What is a thin cylinder ?What are the stresses a thin cylinder is subject to? State their formula's?

Ans : A cylinder is said to be 'THIN' if the ratio of its inner diameter to the thickness of wall is more than 20.

When a thin cylinder is subjected to internal pressure , there are three stresses it is subjected to namely,

- Circumferential or Hoop stress

- Longitudinal or axial stress

- Radial Stress. ( Generally this stress is neglected for thin cylinders due to its very small value)

Circumferential or Hoop Stress : The stress which resists the failure of thin cylinder along the circumference is called circumferential stress or hoop stress.

It is given by formula

Longitudinal Stress : The stress which resists the failure of cylinder in longitudinal direction is called longitudinal stress.

It is given by formula

From the two equations it is obvious that the circumferential stress is TWICE the longitudinal stress.

Q.2) What is a THICK cylinder? Give its examples?What stresses are induced in thick cylinder

Ans : A cylinder is said to be 'THICK' if the ratio of its inner diameter to the thickness of wall is less than 20. Examples are Hydraulic cylinders, high pressure pipes and gun barrels.

A thick cylinder when subjected to internal pressure is subjected to following stresses,

- Tangential stress.(Highest magnitude at inner surface an gradually decreases towards outer surface)

- Radial stress. (This is neglected in thin cylinders)

- Axial or longitudinal stress.

Q.3) Write Lame's equation for thick cylinder, name various terms used in equation,When it is used to find wall thickness?

Ans : Lame's equation is used to find the thickness of the thick cylinder subjected to internal pressure, It is given by,

Where,

- t= thickness of thick cylinder

- Di= Internal diamter of thick cylinder,

= Allowable tensile stress in the material of thick cylinder

- Pi= Internal pressure in the thick cylinder.

Use of Lame's Equation : Lame's equation is based on maximum principal stress theory of failure, as this theory is more suitable for brittle materials, Lame's equation is also applicable to brittle materials like Cast iron or Cast Steel.

Q.4) Write Clavarino's equation for thick cylinder, name various terms used in equation,When it is used to find wall thickness?

Ans : Clavarino's equationis used to find the thickness of cylinder when the material is ductile and cylinder has closed ends, it is given by

Where,

- t= thickness of thick cylinder

- Di= Internal diamter of thick cylinder,

= Allowable tensile stress in the material of thick cylinder

-

- Pi= Internal pressure in the thick cylinder.

Poissons ratio for the material.

Q.5) Write Birnie's equation for thick cylinder, name various terms used in equation,When it is used to find wall thickness?

Ans : Birnie's equation is used to find thickness of thick cylinders, which are madeup of ductile material and are open ends.

Where,

- t= thickness of thick cylinder

- Di= Internal diamter of thick cylinder,

= Allowable tensile stress in the material of thick cylinder

-

- Pi= Internal pressure in the thick cylinder.

Poissons ratio for the material.

The only difference between Clavarino's equation and Birnie's equation is that there is in Clavarino's equation in numerator, where as there is only

in Birni's equation.

Q.6) What is autofrettage, What are the methods of Prestressing the cylinder?

Ans : Autofrettage is the process of pre-stressing the cylinder before actually putting it into cylinder. In it done to increase the pressure bearing capacity of cylinder. It is the technique to induce the reverse residual stress in the cylinder so that when put in service, some part of actual stress is cancelled in nullifying the residual stress, thus increasing the pressure bearing capacity.

Following are the methods of Prestressing

1) Shrinking the cylinder : In this method a composite cylider is formed by shrinking an outer cylinder on inner cylinder and thereby inducing compressive stress on inner cylinder.

2) Overloading the Cylinder : In this method the pressure is adjusted in such a way that a portion of the cylinder near the inner diamter is subjected to stresses in plastic range of material whereas the outer portion is in elastic range. On releasing the pressure the out portion causes the residual compressive stresses on inner surface

3) Wire Winding method : In this method a wire under tension is wound around the cylinder, with an intention to produce compressive stresses in the cylinder.

NUMERICAL PROBLEMS

1)The following data refers to single acting hydraulic cylinder.

Pressure of hydraulic fluid = 10 MPa

Operating force available at the piston rod = 10 KN

Friction due to piston ring and stuffing box = 10% of operating force

Thickness of cylinder flange = 10 mm

Thickness of cylinder head = 8 mm

Cylinder and, cylinder head material = FG200

Modulus of elasticity for FG200 = 100 GPa

Thickness of Zinc gasket = 3 mm

Modulus of elasticity for zinc = 83 GPa

Number of bolts = 4

Preload in each bolt = 2.8 KN

Bolt material = FeE400

Modulus of elasticity for FeE 400 = 207 GPa

Factor of safety for cylinder = 5

Factor of safety for bolts = 6

Standard diameter of cylinder = 20, 30, 40, 50, 60 mm

Standard Thickness of cylinder = 2, 4, 5, 6, 7, 8, 10 mm

Standard diameter of bolts = 8, 10, 12, 14 mm

Determine :

i) Inner diameter of cylinder

ii) Thickness of cylinder

iii) Diameter of bolts

2)The maximum tensile stress induced in a pressure cylinder consisting of an inner cylinder of 300mm ID and 400mm OD is 100N/mm2 . The vessel is jacketed by outer cylinder of 500mm OD. Calculate the shrinkage

pressure and the difference between the inner cylinder OD and the jacket ID before assembly assuming E = 210kN/mm2 .

3)The piston rod of a hydraulic cylinder exerts an operating force of 12kN. The friction due to piston packing and stuffing box is equivalent to 10% of the operating force. The pressure in the cylinder is 10 MN/m2 . The cylinder is made of cast iron FG 200 and factor of safety is 5. Determine the diameter and thickness of cylinder.

4)A hydraulic cylinder with closed ends is subjected to an internal pressure of 15 MPa. The inner and outer diameters of the cylinder are 200 mm and 240 mm respectively. The cylinder material is cast iron FG 300. Determine the factor of safety used in design. If the cylinder pressure is further increased by 50%, what will be the factor of safety?

5)The piston rod of a hydraulic cylinder exerts an operating force of 10 kN. The friction due to piston packing and stuffing box is 10% of the operating force. The pressure in the cylinder is 10 MPa. The cylinder is made up of FG 200 and factor of safety is 5. Determine the internal diameter and thickness of the cylinder. The flange thickness is 10 mm and CI cover plate of thickness 10 mm is fixed to the cylinder by means of 4, M10 bolts and a zinc gasket of 3 mm thickness. The bolts are made up of Fe400. Determine the factor of safety for bolts.

E steel = 207 GPa

E CI = 100 GPa

E zinc = 90 GPa

Assume a preload of 20 kN in each bolt.

Std. Dia. of cylinder 20, 30, 40, 50, 60 mm

Std. Thickness 2, 4, 5, 6, 7, 8, 10 mm B

-

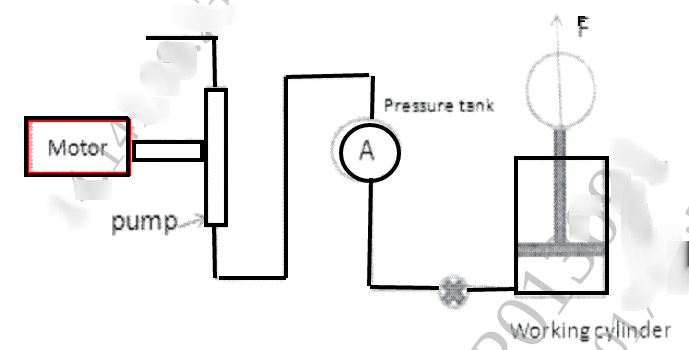

A hydraulic control for a straight line motion as shown in fig. utilizes a spherical pressure tank A connected to a working cylinder B. The pump maintains a pressure of 3 MPa in the tank. i) If the diameter of pressure tank is 800 mm, determine its thickness for 100% efficiency of the joint. Assume the allowable tensile stress as 50 MPa. ii) Determine the diameter of a cast iron cylinder and its thickness to produce an operating force F = 25 KN. Assume 1) An allowance of 10% of operating force F for friction in the cylinder and pacing and 2)A pressure drop of 0.2 MPa between the tank and cylinder. Take safe stress for cast iron as 30 Mpa. iii)Determine the power output of the cylinder if the stroke of the piston is 450mm and time required for the working stroke is 5 seconds. iv)Find the power of the motor if the working cycle repeats after every 30 seconds and the efficiency of the hydraulic control is 80% and that of 60%.

7)A hydraulic cylinder, made of gray cast iron FG 300, is subjected to an internal pressure of 15 MPa. If the inner and outer diameters of the cylinder are 200 mm and 240 mm respectively, determine the factor of safety. If the cylinder pressure is further increased by 30 %, What will be the factor of safety.

8)A high pressure cylinder consists of steel tube with inner and outer diameters of 20mm and 35mm respectively. It is jacketed by outer steel tube with an outer diameter 50mm. The tubes are assembled by shrinking

process in such a way that maximum principal stress induced in any tube is limited to 115Mpa . Calculate the interference pressure and original dimensions of tubes. Assume E=207000 N/mm2 .

9)A high pressure cylinder consists of steel tube with inner and outer diameters of 45mm and 65mm respectively. It is jacketed by outer steel tube with an outer diameter 85mm. The tubes are assembled by shrinking

process in such a way that maximum principal stress induced in any tube is limited to 150N/mm 2 . Calculate the interference pressure and original dimensions of tubes. Assume E =207000 N/mm 2 .

10)The hydraulic cylinder 400 mm bore operates at a maximum pressure of 5 N/mm 2 . The piston rod is connected to the load and the cylinder to the frame through hinged joints. Design (1) cylinder (2) piston rod (3) hinge pin. The allowable tensile stress for cast steel cylinder and end cover is 80 MPa and for piston rod is 60 MPa. Take τ = 45 N/mm 2 for hinge pin Draw the hydraulic cylinder with piston & piston rod.

11)A high pressure cylinder consists of a steel tube with inner and outer diameters of 20 mm and 40 mm respectively. It is jacketed by an outer steel tube having an outer diameter of 60 mm. The tubes are assembled by a shrinking process in such a way that maximum principal stress induced in any tube is limited to 100 N/mm 2 . Calculate the shrinkage pressure and original dimensions of the tube E = 207 kN/mm 2 .

12)A compound cylinder consists of an inner steel tube with inner and outer diameters of 40mm and 60mm respectively. It is reinforced by shrinking a steel jacket of outer diameter 80 mm . the compound cylinder is subjected to an internal pressure of 60 Mpa. The shrinkage allowance is such taht the maximum circumferential stresses in inner tube and jacket are same calculate 1) the intererence pressure and 2)The origional diamensions of inner tube and jacket take E = 207 kN/mm2

- Log in to post comments