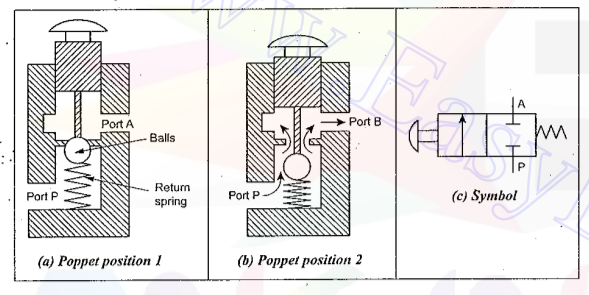

Q.1.What is check valve? Explain with sketch

The purpose of check valve is to block the flow of fluid in a given direction, but to permit unrestricted flow in the opposite direction. For this reason they are also known as “ Non return valves”. The flow blocking is required absolutely leak free hence these valves are always of poppet typeconstruction. Check valves are the inherent elements in any hydraulic circuit, they are meant for various purposes in the hydraulic circui

Check valves can be used for any function that requires the flow to be blocked in one direction and allowed in another direction. Following are some typical

applications,

1) Holding load,

2) With flow control valve.

3) Anti-cavitation valve with pumps or motors,

4) Bypass for clogged suction line,

5) By pass for clogged return line.

Q.2.Explain with sketch 2/2 Direction control valve

Ans :

A 2/2 valve is one which has 2 port connections and two positions only. The valve shown below is normally closed type(it can be normally open type

also). Its construction is simply a spring loaded ball which is actuated by pressing the button. In normal position the connection

between port 'P' and port 'A' is closed. But when the operator presses the valve manually, it opens the connection between the port P and Port A., thus allowing the fluid to pass to port A.

This valve is used for actuating single acting cylinder, which doesn't needs oil/air for returning. It may be gravity or spring return cylinder.

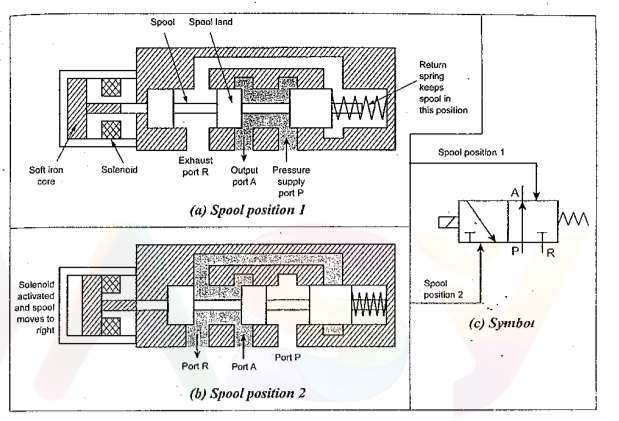

Q.3.Explain with sketch 3/2 Direction control valve

A 3/2 valve is one which has 3 port connections and two positions only. The valve shown below is normally open type(it can be normally closed type also). Its construction is simply a Spool which separates the different ports,which is actuated by force. In normal position the port 'P' and port 'A' are connected. But when the operator presses the valve manually, it connects A to R and port P is idle.

This valve is used for actuating single acting cylinder, Its symbol is also shown besides.

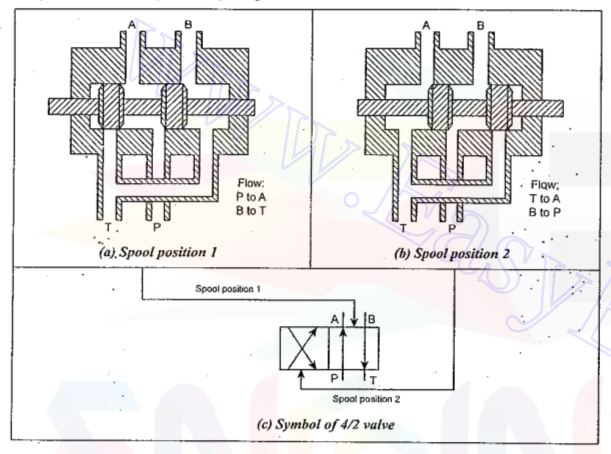

Q.4.What is 4/2 DC valve? Explain with sketch

A 4/2 valve is one which has 4 port connections and two positions only. This valve is useful for double acting cylinder. The valve shown below has a

spool which separates the ports, in normal position port T is connected to A and Port B is connected to T.

When the spool is shifted by some means, it alters the connections and connected the Port P to B and Port A to T. Thus it reverses the connections.

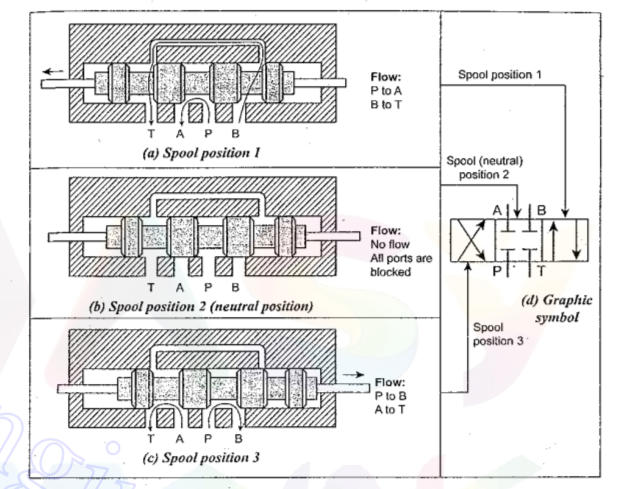

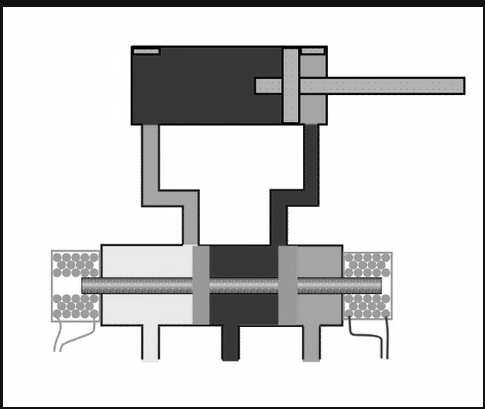

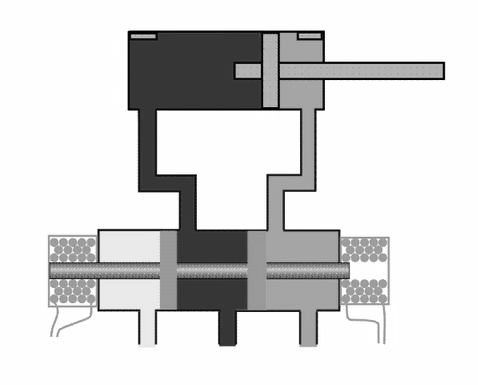

Q.5.What is 4/3 DC valve? Explain with sketch

A 4/3 valve is one which has 4 port connections and three positions only. This valve is useful for double acting cylinder. The valve shown below has a spool which separates the ports.

When the spool is at centre, the oil is not moving to any port and all the ports are disconnected from each other. When the spool is shifted to right,bysome means, it connects P to B and A to T. Whereas when it is shifted to left it connects P to A and B to T.

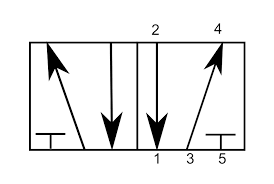

Q.6.What is 5/2 DC valve? Explain with sketch

As shown in figure above the 5 ports and two position valve is a bit modification of 4/2 valve, with one additional port.

A 5/2 valve is one which has 5 port connections and two positions only. This valve is useful for double acting cylinder. The valve shown below has a

spool which separates the ports, in normal position port P is connected to B and Port B is connected to T and R is idle port

When the spool is shifted by some means, it alters the connections and connected the Port P to A and Port B to R , and T port is idle this time. Thus it

reverses the connections, causing the cylinder to move in reverse direction.

Q.7.What is 5/3 DC valve? Explain with sketch

As shown in figure above the 5 ports and three position valve is a bit modification of 5/2 valve, with one additional position.

A 5/3 valve is one which has 5 port connections and three positions . This valve is useful for double acting cylinder. The valve shown below has a spool which separates the ports, in neutral central position all ports are disconnected with each other. When shifter to right position port P is connected to A and Port B is connected to T and R is idle port

When the spool is shifted by some means, it alters the connections and connected the Port P to B and Port A to R , and T port is idle this time. Thus it reverses the connections, causing the cylinder to move in reverse direction

- Log in to post comments