Draw the sketch of multiplate clutch and describe its construction

and working.

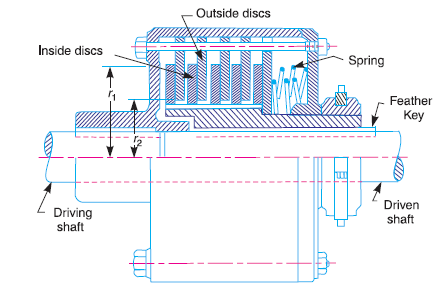

Multi – Plate clutch consists of a number of clutch plates instead of only one clutch plate like in

the Single plate clutch.

Friction surface also increased because of a number of clutch plates. Because of number of

friction surfaces, the capacity of the clutch to transmit torque is also increased.

The plates are alternately fitted to the engine crankshaft and gearbox shaft. They are firmly

pressed by strong coil springs and assembled in a drum type casing.

Each of the alternate clutch plate slides on the grooves on the flywheel and the other slides on

splines on the pressure plate. Thus, each alternate clutch plate has inner and outer splines.

A multiple disc clutch, as shown in Fig., may be used when a large torque is to be transmitted.

The inside discs (usually of steel) are fastened to the driven shaft to permit axial motion (except

for the last disc). The outside discs (usually of bronze) are held by bolts and are fastened to the

housing which is keyed to the driving shaft. The multiple disc clutches are extensively used in

motor cars, machine tools etc.

Let n 1 = Number of discs on the driving shaft, and n 2 = Number of discs on the driven shaft.

Number of pairs of contact surfaces,

n = n 1 + n 2 – 1

and total frictional torque acting on the friction surfaces or on the clutch,

T = n.μ.W.R

where R = Mean radius of the friction surfaces