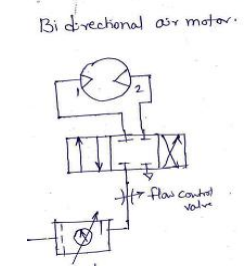

How can the speed control of any actuator be achieved? Explain the speed control circuit of bi directional air motor with sketch.

Speed control of any actuator (Cylinders or motors) can be controlled using flow control valves. Varying the rate of flow of oil will vary the speed of the actuator.(Explanation 1Mark) In meter in circuit, rate of flow of oil is controlled at inlet of the actuator. In meter out circuit, rate of flow of oil is controlled at outlet of the actuator. In bleed off circuit, rate of flow of oil is controlled in the by-pass line leading towards the tank. Speed control of bi-directional air motor: (Sketch 1Marks and Explanation 2 Marks) Bi-directional air motor rotates in clockwise as well as anti-clockwise direction. The speed of bi-directional motor is controlled as shown in fig. The speed control of motor by using variable two flow control valves having built-in check valve and 4x3 DC valve having zero position or central hold position with lever L1 and L2. When lever L1 is operated, port P will be connected to port A of air motor and motor will start rotating in clockwise direction. Its speed can be controlled by using variable flow control valve F1. Port B of motor will be connected to exhaust R and air in motor will be exhausted through port R via DC valve. When lever L2 is operated, pressure port P will be connected to port B of motor and naturally motor will start rotating in anticlockwise direction. Port A will be connected to port R and air in the motor will be exhausted through port R via DC valve.