Important Points to Remember

- The objective of material handling system the moment of materials from one point to another point within the plant

- The material handling system consists of three activities one picking up the material second transporting the load and third sitting down the Lord

- A good material handling system should have, accuracy in low transportation, low operating and initial cost, easy to operate and maintain, and it should give operational safety.

- The loads which are transmitted as large number of homogeneous particles or lumps are called bulk loas, the loads which are transferred as a single unit are called unit load.

- The process of converting the bulk loads or small units into unit load by use of containers is known as containerization.

- The material handling equipments are selected on the basis of direction of load,travel length,type of load,initial and operational costs etc.

- Material handling equipments are mainly classified as Hoisting equipment,Surface and overhead equipment and conveyors.

- Conveyors are group of devices, with no lifting gear, used for moving loads in horizontal or inclined direction, conveyors transmit the material continuously.They can transfer material at very high rates. Buy they can transmit material on fixed routes as well they can not convery heavy unit loads.

- Chain conveyors consists of endless chains running over the drive, which is coupled to drive unit. Chain conveyors can transport large and heavy loads, but they need regular lubricaiton and alignment.

- Screw conveyors consists of screw or worm in the form of helix.In this the material is moved due to axial movement, screw conveyors can handle hot as well as wet material.

Theory Questions and Answers on Design of material handling system

Q.1. What is system concept of material handling or Enlist the criterion which must be fulfiled by a material handling solution?

Ans : Any solution of the material handling problem should satisfy the following conditions

- Easy to adopt solution : The solution for the material handling system should be easy to adopt solution.

- Broad and long term solution ; The design of material handling system should address the broad and long term solution instead of temporary quick fix.

- Minimum cost : The solution of the problem should be such that the initial and operation costs should be minimum.

- The solution should not transfer the problems into the other zones of the product cycle.

- The solution should not be prone to rapid obsolence, means the designed system should not become useless as soon as other better alternative is available. The designer should carefully select the best solution for long term use.

Q.2. What are the Objectives/requirement of a good Material Handling system ?

Ans : following are the objectives of good material handling system :

- Accurate transportaion of loads at required place

- Precise picking up of loads

- Transportation in right time and quantity

- Transportation with minimum damage and minimum manpower.

- Simplicity and easy maintenance

- Low initial and operating costs

- Safety in operation

Q.3. State the Guidelines in selecting the material handling equipments or State the factors to be considered while selecting a material handling equipment?

Ans : Different material handling equipments can be used for the same operation, so the selection of proper equipment is one of the key points in successful performance of material handling equipment. Following are the important points to be considered while selecting material handling system.

- Type of Material to be handled : This is the most important point which governs the selection of the material handling equipment. If the material is loose and bulk form then mostly belt converyor is prefered. For the hot materials generally screw conveyor is preffered.

- Direction and length of travel : This is the second important point that governs the selection of the material handling equipment,for the shorter distances hoists and cranes are used whereas for the longer distances belt conveyors are more preferred. As far the direction is considered belts are preferred for the horizontal displacement of material and elevators,hoists and cranes are best for vertical movement.

- Load capacity : The load coming on the converyor system also decides its type and design.

- Type of Production process : This also decides the material handling system. for the foundry, forgings or welding ect. cranes are more used whereas in the assembly shops and food/pharmacuticals belt or roller conveyors are used.

- Plant Layout :Space availability, celling height, Floor strength ect are also important considerations while selecting the material handling equipments.

- Initial and operating costs

- Local conditions

- Stacking possibilities of material at pickup and delivery points etc.

Q.4. What are the different types of Conveyors, explain each in bried with neat sketch?

Q.5. Draw a neat sketch of Layout of a belt conveyor , State the functions of various elements of assembly?

Q.6.Differentiate between 'Angle of repose ' and 'Angle of Surcharge'?

Q.7.What are different belt material used for conveyor belts?

Q.8. State the advantages and limitations of belt conveyor as compared to other conveyors?

Q.9. Explain advantages of TROUGHED conveyor over flat conveyor?

Q.10.Differentiate between 'Angle of repose ' and 'Angle of Surcharge'?

Q.11. Describe various types of idlers and their characterstic with sketches?

Q.12. Describe Gravity take up and Screw take up used in belt conveyor?

Q.13. What do u mean by sag in conveyr belt? how it is minimized?

Q.14. What are different methods of feeding to flat belt conveyors?

Numerical Problems

1) A flat horizontal belt conveyor is to be used for transporting material with mass density of 3 ton/m 3 . The belt is 1m wide and has speed of 2 m/s Determine capacity of conveyor if surcharge angle is 20°.

2) A triple ply belt conveyor is required to transport 4 tons of iron ore per hour at a conveyor speed of 3 m/sec. If the mass density of iron ore is 2.5 tons/m 3 . Suggest : a) The maximum suitable inclination for the conveyor b) The diameter of the drive pulley c) The gear box reduction ratio, if motor speed is 1440 rpm. Use following data:

3) A triple ply belt conveyor is required to transport 2 ton of iron ore per hour through a distance of 1000m and a height of 300 m. The permissible belt speed is 90m/min. if the mass density of iron ore is 2.5 ton per cubic meter, determine : (i) the belt width; (ii) the diameter of drive pulley; and (iii) the reduction ratio of gear reducer, if electric motor speed is 1440 r.p.m. Use following data:Standard belt widths : 400,450,500,600,650,750,800,900,100,1200,1400,1600,1800, 2000 mm material factor for plies for Capron belt : K1 = 2.0; belt tension and arc of contact factor : K2 =80.

4) The following data refers to horizontal belt conveyor for carrying bulk material Capacity of conveyor = 250 MT/hr Belt speed = 1.5 m/s Width of the belt = 1200 mm Belt mass per unit length = 18.6 kg/m Mass of each carrying run idler = 30.0 kg Mass of each carrying run idler = 25.0 kg Pitch of carrying run idler = 1.0 m Pitch of carrying run idler = 2.0 m Friction factor for idler = 0.02 Snub factor for snub pulley = 0.03 Snub factor for drive and tail pulley = 0.06 Drive and tail pulley diameter = 500 mm Frictional resistance due to belt cleaner = (100 B) N Where B belt width, m Angle of lap on drive pulley = 200° Coefficient of friction between belt and drive pulley = 0.4 Drive efficiency = 90% Motor speed = 1440 rpm Assume that the bulk material is carried over a length of 300 meters and neglecting resistance at loading station Determine : i) The reduction ratio of gear box and ii) The power required to drive the belt

5) Design a belt conveyor to carry material at the rate of 30×10 3 kg/hr with the following details. Bulk density of material is 800kg/m 3 , angle of bulk material surcharge is 15o, belt speed is 10 km/hr, belt has 4 plies, material factor k 1 for plies is 2.0, belt tension and arc of contact factor k 2 is 63. Determine: i) Suitable belt width ii) Drive pulley diameter and length

6) An inclined belt conveyor is used for loading the mineral ore in a ship. The belt inclination is 20 o for which the flow ability factor k is 2.5 × 10 4 . The belt width is 1000mm while belt speed is 2 m/s. If the specific weight of the mineral ore is 16000 N/m 3 , determine the capacity of the conveyor. {sppu s16}

7) A belt conveyor is to be designed to carry the iron ore at the rate of 350 ton/hour with following details:

Weight density of material = 16700 N/m 3

Angle of repose of material = 15 o

Belt speed = 120 m/min

Material factor for plies k 1 = 2.0

Belt tension and arc of contact factor = k 2 = 70

No.of plies for belt = 4 (Take : C = 0.075, S = 80 mm).

Determine

i) Width for belt.

ii) Diameter and length of drive pulley. {sppu s16}8) A conveyor carrying ore at 300,000 kg/hr has its 4 ply belt moving at 10 km/hr. The bulk density and the angle of surcharge of ore are 800 kg/m 3 and 15 respectively. Taking the material factor for plies (k1) as 2.0 and the belt tension and arc of contact factor (k2) as 63, Find: i) Belt width ii) Drive pulley diameter and length.

9) A three idler troughed belt horizontal conveyor is to be used for transporting 400 ton/hours of iron core having weight density of 1.67*10-8 KN/mm 3 . If the belt speed is 7.2 kmph and surcharge factor is 0.1 calculate the width of belt in mm {SPPU s17}

10) A 20 degree troughing belt conveyor has the following specifications

Material to be conveyed : Lime stone

Maximum lump size 100 mm

Capacity : 300TPH

Inclination : 100

Centre distance : 60 m

1) Determine the width number of plies and the thickness of the belt

2) Select a proper motor for the conveyor

3) Design the drive pulley along with its shaft and also select its bearing.

{MU S16}

11) A 20 Degrees troughing beltconveyor has the following data

Material to be conveyed : Coal (From Mine)

Inclination of conveyor : 10 deg

Lump size : 80 mm

Capacity : 400 tph

Length of conveyor : 120 m

Design the conveyor for

1) Motor power capacity

2) Belt widith

3) No of troughing idlers and return idlers

4) Belt drive pulley {MU W16}

12) Following data relate to a horizontal belt conveyor used for conveying coal

in a thermal power station :

Capacity of conveyor: 1000 ton/hr

Density of coal: 700 Kg/ m 3

Belt speed: 1.4 m/s

Surcharge factor: 0.1

Number of plies: 4

Material Factor K 1 : 2

Belt tension and contact factor K2: 100

Material conveying length: 355m

Center distance between snub pulleys: 350m

Ratio of tail pulley to drive pulley dia. : 1.0

Ratio of snub pulley to drive pulley dia. : 0.5

Mass of each carrying run idler: 25 kg

Mass of each return run idler: 20 kg

Pitch of carrying run idlers: 1m

Pitch of return run idlers: 2.5m

Friction factor for idlers: 0.02

Snub Factor for snub pulleys: 0.03

Snub factor for Drive and tail pulleys: 0.06

Material velocity component along belt drive: 1 m/s

Angle of lap on drive pulley: 200o

Coefficient of friction between belt and pulley: 0.4

Drive efficiency: 93 %

Mass of belt / mm width / mm length = .015kg/mm/m

Motor speed 1440 RPM

Determine following parameters of the conveyor:

Standard belt with rounded off to nearest hundred mm.

Reduction ratio of the gear reducer

Power required to drive the conveyor. {sppu w13}13) Following data relate to a horizontal belt conveyor used for conveying coal in a thermal power station: Capacity of conveyor : 1000 ton/hr Density of coal : 750 kg/m 3 Belt speed : 1.5 m/s Surcharge factor : 0.1 Number of plies : 4 Material Factor K1 : 2 Belt tension and contact factor K2 : 100 Material conveying length : 455m Center distance between snub pulleys : 450 m Ratio of tail pulley to drive pulley dia. : 1.0 Ratio of snub pulley to drive pulley dia. : 0.5 Mass of each carrying run idler : 25 kg Mass of each return run idler : 20 kg Pitch of carrying run idlers : 1 m Pitch of return run idlers: 2.5 m Friction factor for idlers : 0.02 Snub factor for snub pulleys : 0.03 Snub factor for Drive and tail pulleys : 0.06 Material velocity component along belt drive : 1 m/s Angle of lap on drive pulley : 210° Coefficient of friction between belt and pulley : 0.35 Drive efficiency : 95% Mass of belt / mm width / mm length = .015 kg /mm/m Motor speed 1440 RPM Determine following parameters of the conveyor: Standard belt with rounded off to nearest hundred mm. Reduction ratio of the gear reducer Power required to drive the conveyor.

14) A horizontal belt conveyor transports material of mass density 1200 kg/ m 3 . The surcharge factor for the flat belt drive is 0.16 and the belt width is 650 mm. Determine the capacity of the conveyor , if the belt speed is 1.75 m/s and the effective width b(in meters) of the material carried by the belt safely is given by the equation: b = 0.9B 0.05; where B is the belt width in meters. {sppu w15}

15) Design a belt conveyor to carry material at the rate of 3x10 5 kg/ hr with the following details. Bulk density of material is 800 kg/m 3 , angle of bulk material surcharge is 150 , belt speed is 10 km/hr, belt has 4 plies, material factor k 1 for plies is 2.0, belt tension and arc of contact factor k 2 is 63.

Determine:

i) Suitable belt width.

ii) Drive pulley diameter and length. {sppu w15}16) The following data refers to a belt conveyor for carrying bulk material.Capacity of conveyor - 250 metric tons/hr Belt speed 1.5 m/sec Width of the belt -1200mm Belt mass per unit length -18.6kg/m Mass of each carrying run idler -30.0kg Mass of each return run idler -25.0kg Pitch of carrying run idler - 1.0m Pitch of return run idler -2.0m Friction factor for idlers - 0.02 Snub factor for snub pulley - 0.03 Snub factor for drive and tail pulley - 0.06 Drive and tail pulley diameters - 500mm Frictional resistance due to belt cleaner - (100 B)N Where, B is in meters Angle of lap on drive pulley -200° Coefficient of friction between belt and drive pulley 0.4 Drive efficiency -90% Motor speed - 1440 rpm Assuming that the bulk material is carried over length of 300 meters and neglecting resistance at the loading station. i) Determine reduction ratio of gear box ii) Power required to drive the belt conveyor. {sppu w16}

17) Following data refers to a horizontal belt conveyor used for transporting iron ore-

capacity of conveyor = 300×10 3 kg/hour,

belt speed = 180 m/minute,

density of coal (ρ) = 7848 N/m 3 ,

Number of plies for belt(Z p ) = 3,

material factor for plies (k 1 ) = 2,

Belt tension and arc of contact factor for belt (k 2 ) = 60,

Electric motor speed = 1440 rpm,

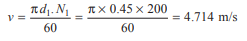

centre distance between snub pulleys, (d 1 ) = 200m,

centre distance between drive and tail pulley (d 2 ) = 240m.

Pitch of carrying run idlers, (t c ) = 1m, Pitch of return run idlers (t r ) = 2.5m.

Surcharge factor = 0.0725 determine :

i) Width of belt

ii) Reduction ratio of gear reducer

iii) The number of carrying and return run idlers. {sppu w16}- Log in to post comments