What is a cotter joint? State any four applications of a cotter joint? Why taper is provided on cotter joint?

COTTER JOINT

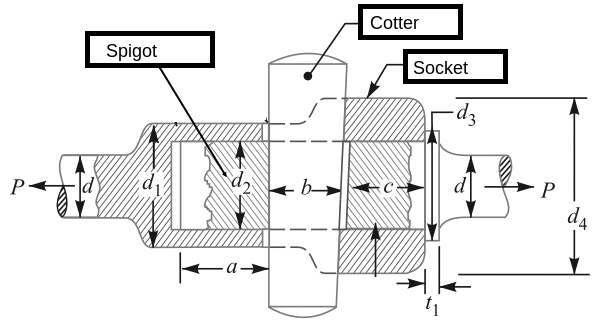

Cotter Joint: " A cotter joint is temporary joint and used to connect two coaxial rods or bars which are subjected to axial tensile and or compressive forces."

It consist of

1) spigot : It is the male part of the joint , it has a rectangular slot for passing the cotter through it. Spigot has a collar which rests against the socket end.

2) socket :It is the female part of the joint, it also has a rectangular slot for passing the cotter through it. It has a circular hole in which spigot fits.

3) cotter : is a wedge shaped piece of metal which actually connects two parts which are non rotating.

Cotter Joint Applications:

1) Lewis foundation bolt

2) connection of the piston rod to cross head of a reciprocating steam engine.

3) valve rod & its stem 4) piston rod to the trail end in an air pump.

5) Cycle pedal sprocket wheel.

Cotter joint taper why and how much?

Cotter is a flat wedge shaped metal piece which is used to connect two rods which transmit the force but without rotation. The force may be axial and of tensile or compressive nature. Cotter is fitted in the tapered slot and remains in its position because of wedge action. This happens because of taper.

Because of taper,

i) It is simple to remove the cotter and dismantle the joint parts.

ii) Taper ensures tightness of the joint in operation and it prevents slackening of the parts.

Generally the value of taper on cotter is 1 in 48 to 1 in 24.

1 in 48 means that there will be reduction of 1 mm in size after the length of 48 mm, and 1 in 24 means there will be reduction in size of cotter by 1 mm after 24 mm.

Link to other chapters in machine design

http://mechdiploma.com/elements-machine-design-syllabus22564