Q.1. Why pressure relief valve is used in hydraulic circuit?

Ans :

Pressure Relief Valve used because;

1. To Maintain desired pressure levels in the circuit.

2. To set maximum pressure in hydraulic system.

3. Protect the pump and other system components from overloading.

4. It acts as a relief and safety device

Q.2. Explain with sketch pressure relief valve.

Ans :In its simplest form directly operated pressure relief valve consists of a casing fitted with acone (or spool) which block the flow of pressurized fluid due to spring force (F). The spring force can be adjusted by tightening or

loosening the screw.

If input pressure p is effective on an area A. The resulting force F, when exceeds the spring force, the valve body (cone or spool) movesin a direction opposite to the force of spring and opens a connection between the inlet and outlet. The pressure level, which is to be maintained, is thus controlled by spring force..

Q.3.What is the need of pilot operated pressure relief valve?

Ans :When relief valve is to be used for higher pressure and higher flows, its size increases considerably and spring goes on becoming much heavier. Eventually a stage is reached where these springs are so strong that they can not be adjusted and where they need too much space. For this reason appropriate sized

and easy to use pressure control valves for large flow through quantities are provide with pilot operation.

Q.4. Explain with sketch working of pilot operated pressure relief valve?

Ans : All the pilot operated valves

(Whether it may pilot operated pressure valve or pilot operated flow

or pilot operated direction control valve) work on the same principle

of flow through orifice. It is well known that when the fluid flows

through an orifice its pressure drops due to internal resistance to

flow (back-pressure). Thus as shown above P1 > P2. This

principle is used to actuate the spool in control valves.

Construction: The valve as shown in fig 8.5 consists of two stages namely main and pilot stage. The main valve is biggest in size (to allow more flow), and the pilot

stage is a small directly operated relief valve with small spring. The input pressure is applied to the lower end of the main valve, andthe same is applied to the cone of pilot valve through an orifice. The orifice can either be located in the spool or housing.

Operation:

The pressure applied at the end of main stage is same as the pressure applied on the cone of small relief valve. (One pointshould very clear that pressure difference occurs only when there is flow through orifice and when there is no flow pressure is equal on all parts it is connected to). Since area of cone is intendedly kept

small, hence for a given pressure very small spring can be used (Since pressure is ratio of force and area, as area is less for samepressure force is also less in same ratio). Thus small springs can control higher pressures, but they can not allow the required flow. Hence bigger spool is applied in second stage to allo higher flows. When the pressure in the system exceeds the limit, which is set by spring of pilot stage, the cone is lifted allowing smaller flow to drain. The flow through the

orifice causes the pressure difference on bottom and the top of the spool, which results in differential force which moves the spool inupward direction, opening the passage of fluid to drain, and thus allowing higher flow of fluid to drain.

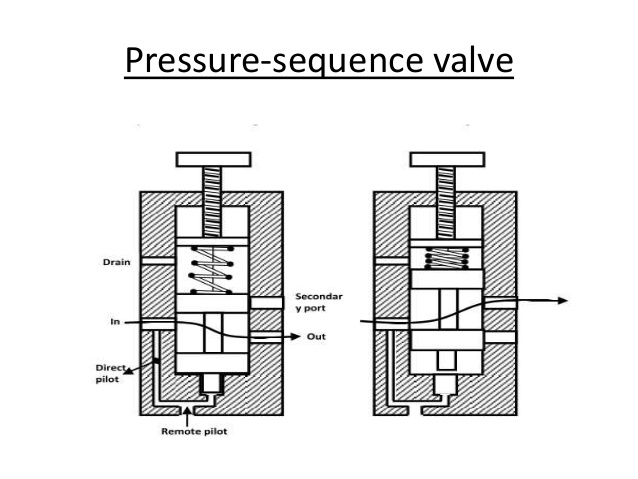

Q.5. What is sequencing valve? Explain with sketch

Ans : The function of a sequence valve is to provide flow to a second consumer in the case when the pressure level at a particular consumer has reached a threshold valve. As the name implies it is used for sequencing the operations one after

another.

Constructional details :

The Construction of a sequence valve is shown in fig it is nothing but a pilot operated relief valve, inwhich the drain is connected to second consumer. As shown it has two spools attached to each other. The spools are drilled with internal orifice. The drain is directed to the main drain.

Operation :

In normal position the sequence valve is closed. When the operation of consumer 1 is completed, the pressure starts building, and when reaches set value of pilot relief valve, it lifts the spool up and this movement causes the blocking of flow to first consumer and opening to second consumer.

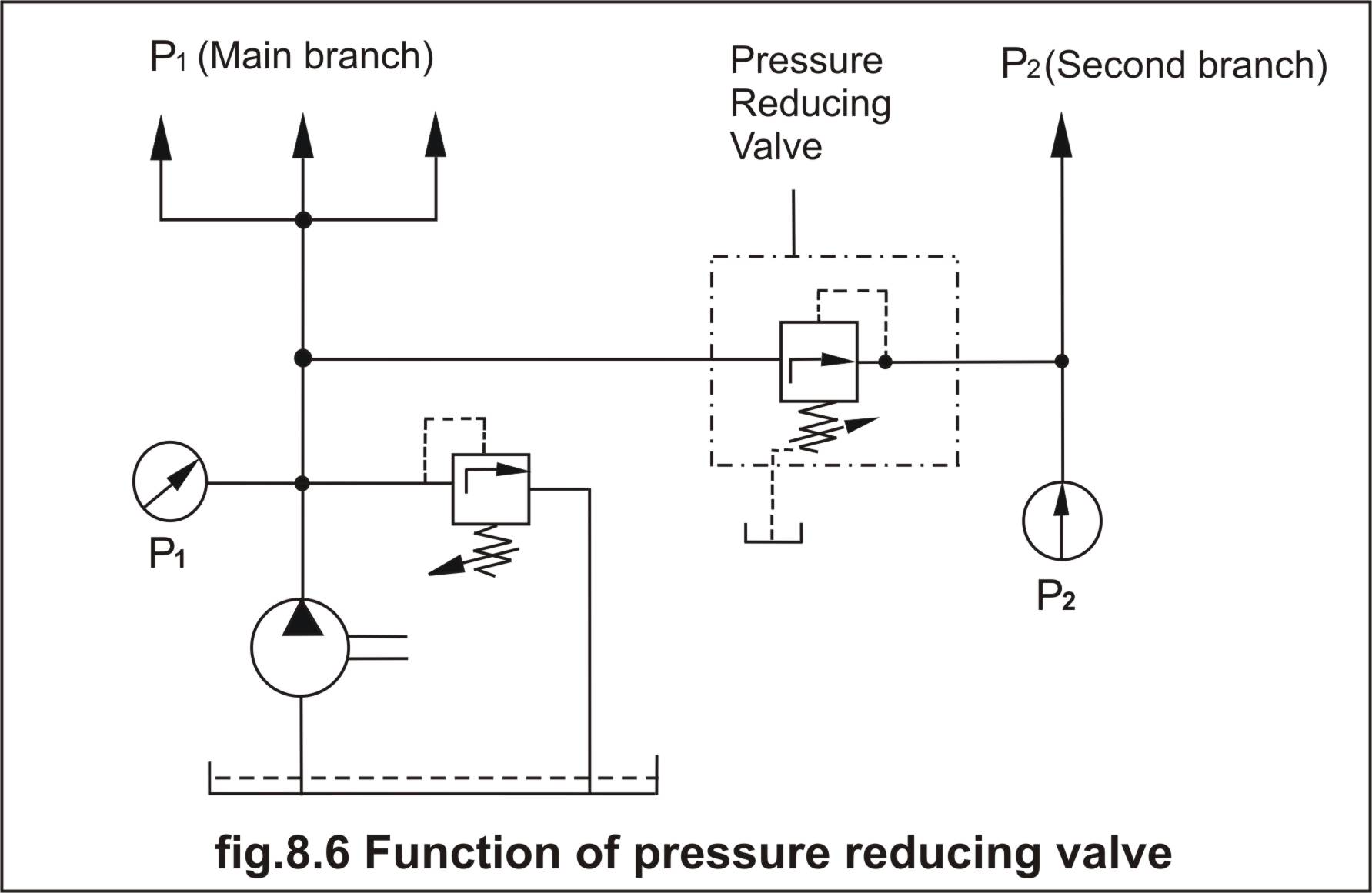

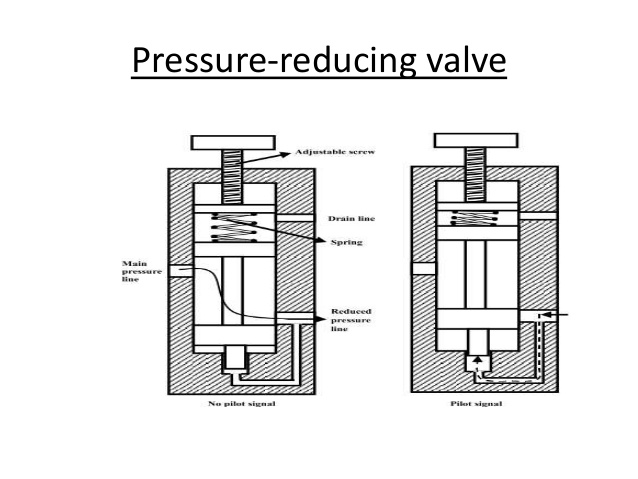

Q.6. What is the function of Pressure reducing valve?Explain with sketch pressure reducing valve?

Ans :Function of pressure reducing valve : The function of pressure relief valve is to limit the pressure in the complete system to a given level. The task of a pressure reducing valve, on the other hand, is to reduce pressure in a particular branch of the circuit to different level on demanded by

consumer in that branch.

Construction and Working :

Working

• This type of valve (which is

normally open) is used to maintain reduced pressures in specified

locations of hydraulic systems. It is actuated by downstream pressure

and tends to close as this pressure reaches the valve setting.

• A pressure-reducing valve uses a

spring-loaded spool to control the downstream pressure. If downstream

pressure is below the valve setting, the fluid flows freely from the

inlet to the outlet.

• When the outlet (downstream) pressure

increases to the valve setting, the spool moves to the right to

partially block the outlet port. Just enough flow is passed to the

outlet to maintain its preset pressure level. If the valve closes completely, leakage past the spool causes downstream pressure to build up above the valve setting.

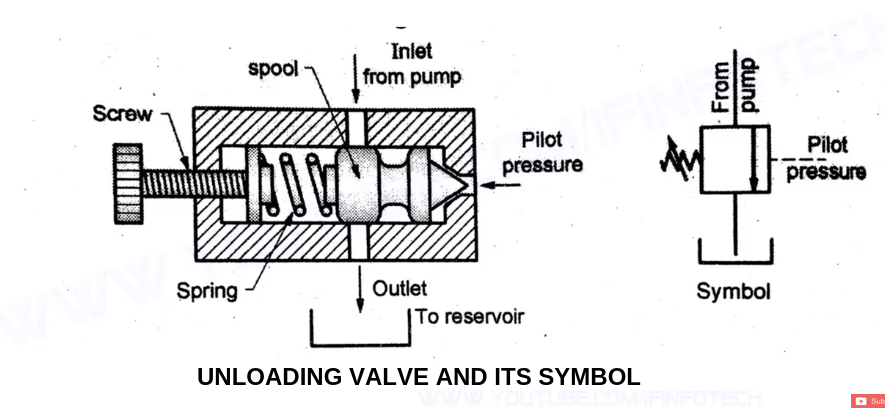

Q.7. What is the function of Unloading valve?Explain with sketch Unloading valve?

Ans :Function of Unloading

valve : Unloading valve is a pressure control device

that is used to dump excess oil to tank at little or no pressure. Using the pressure relief valve to direct the oil to tank when the actuator doesn't needs it causes lot of energy loss. Because the pump has to force oil against the pressure of pressure relief valve setting. This results in lot of heat development and also loss of energy. This problem is solved by unloading valve, the unloading valve allows the pump to deliver back the oil to tank at literally zero pressure, thus saving the energy.

Construction and working of Unloading valve:

As shown in figure its construction is similar to the pressure relief valve except that the actuation is by pilot pressure. When the pilot pressure reaches the required level, the valve shifts to left and all excessive oil is drained to the tank as very less or zero pressure. When the pilot pressure drops means the

actuators are needing the oil, the spring causes the spool to move to right resulting in closure of valve and hence the pump oil is not

sent to tank but to actuator.

Application: It is used in system with

accumulator, and also in high low pump circuit.

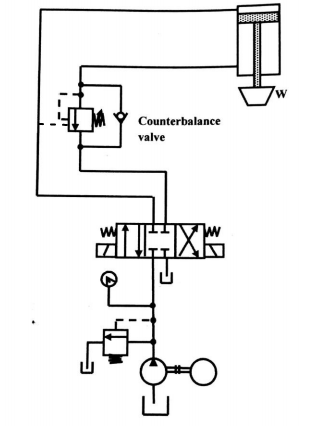

Q.8. What is the function of Counter balance valve?Explain with sketch Counter balance valve?

Ans :Function of counter balance valve : The function of counter balance valve is to prevent a load from accelerating uncontrollably. This situation

can occur in vertical cylinders in which the load is weight.

Construction and working circuit:

As shown in figure when the main DC valve is at centre position there is possibility that the cylinder may fall down due to gravity and load effect. It is prevented by the counter balance valve. The counter balance valve is only actuated when there is pressure in the upper line, thus preventing the dropping of the cylinder.

- Log in to post comments