Key Points to Remember

- A Pressure vessel is defined as a container pipeline which is used for storing carrying fluids under pressure

- An unfired Pressure vessel is defined as a container or pipeline which is used for storing carrying steam, gases or liquid at a pressure above atmospheric pressure.

- The unfired pressure vessels are classified into the following three classes (1) class 1 Pressure vessel (2) class 2 Pressure vessel (3) class 3 Pressure vessel.

- The pressure vessels are manufactured from metal plates bar bending and then welding them.

- Weld joint efficiency is defined as the ratio of strength of the welded joint to the strength of the plates.

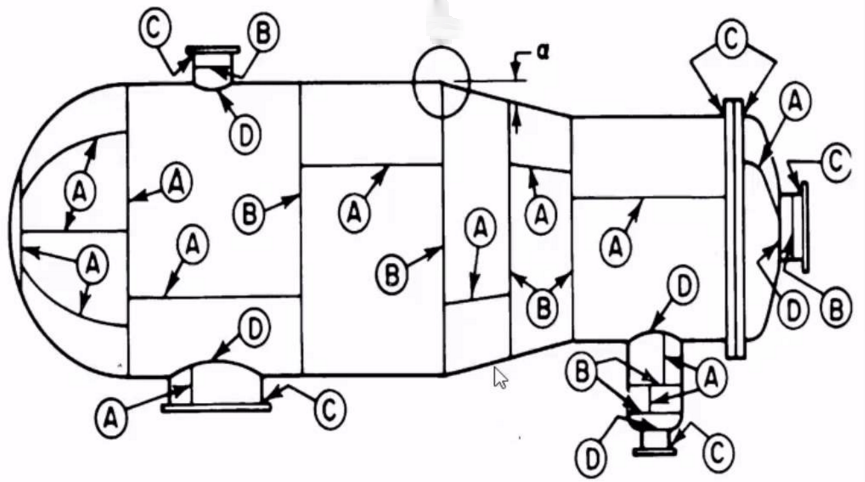

- in case of pressure vessels the term weld category defines the location of particular welded joint in that Pressure vessel, the weld category does not represents the type of welded joint. the weld category in pressure vessels are of four types category A, category B, category C, category D

- The cylindrical pressure vessels are closed at ends buy two types of enclosure 1) flat heads 2) formed heads. the formed hates which are commonly used in pressure vessels are normally fabricated from a single circular flat plate by the process of forming. following are the different types of formed heads used in pressure vessels 1) plain form height 2) torispherical dish head 3) semi-elliptical dished head 4) hemispherical head 5) conical head.

Questions and Answers on Pressure vessel Design

Q.1. State and Explain various categories of welded joints used in unfired Pressure Vessel with a neat sketch.

Ans : there are four categories of welded joints in unfired Pressure vessel

- Category A: this category consists of longitudinal welded joints, within the main shell, communicating Chambers and nozzles, circumferential joints connecting the end closer to the main shell as well as any welded joint in spherical or formed head.

- category B: this category includes circumferential welded joints in the main shell, communicating Chambers of nozzles.

- category c : this category consists of welded joints connecting flanges and Flat heads to the main shell.

- category d : it consists of connecting communicating Chambers and nozzles to the main shell.

Q.2. Explain the different types of pressure vessel as per IS:2825.

Ans : The welded pressure vessels covered by this code shall conform to one of the classses, Each class of construction provides for the use in design,a joint efficiency factor associated with the material, quality control , inspection and tests prescribed for that class.

| Class I Vessels | Class 2 Vessels | Class 3 Vessels |

|---|---|---|

|

All pressure vessels which do not fall either in Class 1 or Class 3. |

|

| Weld Joint efficiency factor = 1.0 | Weld Joint efficiency factor = 0.85 | Weld Joint efficiency factor = 0.50-0.70 |

| No limit for the thickness of the plate. | Maximum thickness of plate should be below 38 mm after adding corrosion | Maximum thickness of plate should be below 16 mm before adding corrosion allowance. |

| Welded joints in this clash are fully radiographed | The welded joint in this class of pressure vessels are Spot radiographed | The welde joints in this class of pressure vessel are not radiographed. |

| Welded joint used are Double welded butt joint with full penetration and Single welded butt joint with backing strip. | Welded joints used are same as clas 1 vessels | In addition to class 1 joints these vessel may have single welded butt joint without backing strip or single fillet lap joints for circumferential joints only. |

| Examples of class 1 pressure vessels are Hydrocyanic acid, caronyl chloride,cyanogen etc. |

Origional file of IS 2825 :1969 code is attached at the end of this document .

NUMERICAL PROBLEMS

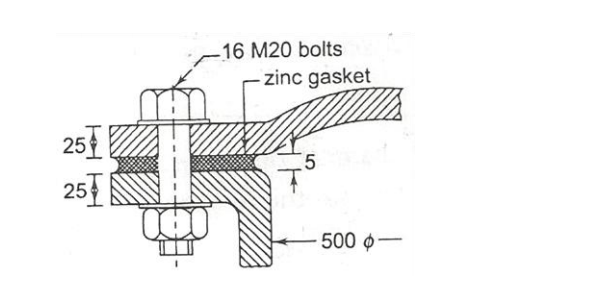

1) The cover of a cylindrical pressure vessel made of cast iron is shown in fig.1 The inner diameter of the cylinder is 500 mm and the internal pressure is limited to 2MPa. The cover is fixed to the cylinder by means of 16 bolts with a nominal diameter of 20 mm. Each bolt is initially tightened with a preload of 20 KN. The bolts are made of steel FeE250 (S yt = 250 N/ mm 2 ). Assume. E for steel = 207 KN/mm 2 ,E for cast iron = 100 KN/mm 2, E for Zinc = 90 KN/mm 2,Determine the factor of safety for bolts considering the effect of the gasket.

2) A 103 capacity cylindrical pressure vessel with torispherical heads is to be used to store water at a temperature of 160o C (Water vapour pressure 6.4 bar absolute). The crown and knuckle radii for the torispherical heads are taken as 0.75 di and 0.125 di respectively. The shell as well as heads is made of plain carbon steel with allowable tensile stress of 85 N/mm2 . The single welded butt joints with backing strips are used to fabricate the vessel. The total length of the vessel is limited to 5m. i) Which class vessel is to be used for this purpose? ii) Determine minimum vessel diameter and the corresponding thickness of the vessel shell. iii) Determine dimensions of the torispherical head. Assume weld joint efficiency or shell & head = 0.9

3) The cylindrical pressure vessel shell of inside diameter 1500 mm is subjected to an internal pressure of 2 MPa. The shell as well as head are made of low alloy steel with an ultimate tensile strength of 450 N/mm 2 the double welded butt joint which are spot radiographed are used to fabricate the vessel. The corrosion allowance is 3 mm. Determine the thickness of cylindrical shell and the thickness of head if the heads are : i) Flat ii) Plain formed iii) Torispherical with crown radius of 1125 mm iv) Semi elliptical with ratio of major axis to minor axis as 2. v) Hemispherical vi) Conical with semi cone angle 30 °.

4)Determine the inside diameter of shell and the crown radius of the torispherical heads if the thickness of the shell and the torispherical heads of a cylindrical pressure vessel are 12mm and 16mm respectively. The vessel operating at 2.0 MPa pressure is entirely made of 270N/mm 2 yield strength material with weld joint efficiency 0.7 and corrosion allowance of 2mm.

5)A pressure vessel consists of a cylindrical shell with an inner diameter of 1500mm and thickness of 20mm. It is provided with a nozzle with an inner diameter of 250 mm and thickness of 15 mm. The yield strength of the material for the shell and nozzle is 200N/mm 2 and the design pressure is 2.5 MPa. The extension of the nozzle inside the vessel is 15mm. The corrosion allowance is 2mm, while the weld joint efficiency is 0.85. Neglecting the area of welds, determine whether or not a reinforcing pad is required for the opening. If so, determine the dimensions of pad made from a plate of 15mm thickness.

6)A horizontal pressure vessel consists of a cylindrical shell enclosed by hemispherical ends. The volumetric capacity of the vessel should be approximately 2m 3 and the length should not exceed 3m. Assuming the thickness negligibly small compared with overall dimensions of the vessel, determine the internal diameter and the length of the cylindrical shell. The pressure vessel is fabricated from steel plates with a yield strength of 225 N/mm 2 . The weld joint efficiency factor is 0.85 and corrosion allowance 2mm the pressure vessel is subjected to an operating pressure of 2Mpa. Calculate the thickness of the cylindrical shell and the hemispherical end closures.

7)A cylindrical pressure vessel shell of inside diameter 1500 mm is subjected to an internal pressure of 2 MPa. The shell as well as the heads are made of low alloy steel with sult = 450 MPa. Double welded butt joints which are spot radiographed are used to fabricate the vessel. Corrosion allowance is 3 mm. Determine the thickness of the cylindrical shell and thickness of head if the heads are i) Flat ii) Plain formed iii) Torispherical with crown radius of 1125 mm.

8)A cylindrical pressure vessel with 1500 mm inside diameter & 15 mm thick is subjected to an internal pressure of 1.5 N/mm 2 . A nozzle of 300 mm inside Diameter & 12mm thickness is to be provided in the shell. Welds joint efficiency for shell as well as nozzle is 85% while corrosion allowance is 2 mm. The nozzle project 20 mm on outside & 30 mm on inside of shell. If the allowable tensile stress for the shell & nozzle material is 120 N/mm2 Determine, whether the reinforcement is adequate, if not find the dimensions of reinforcing pad if plate thickness is 15 mm.

9)A high pressure vessel consist of steel tube with inner & outer diameter 20mm & 40mm respectively. It is a jacketed by an outer tube having outer diameter 60 mm. The tubes are assembles by shrinking processes in such a way that maximum principal stress induced in any tube is limited to 100 N/mm 2 . Assume modulus of elasticity is 207 KN/mm 2 ,Calculate. i) Shrinkage pressure ii) Original Dimensions of tube

10)A cylindrical pressure vessel of 1100mm inner diameter is provided with a nozzle of 155mm inner diameter and 10mm thickness. Protruding lengths of nozzle inside and outside the vessel are 15mm and 10mm respectively and it is made up of seamless tube. The thickness of shell is 10mm. Internal pressure in the shell is 3MPa. The corrosion allowance is 1.5mm. Permissible tensile stress for shell and nozzle material is 200MPa. Design the dimensions of reinforcing pad if required. The reinforcing material is of same quality as that of the shell and is available in thickness of 10mm. (Take weld efficiency as 85%).

11)A cylindrical pressure vessel of 1500mm ID is provided with a nozzle of 330mm inner diameter and 10mm thickness. Protruding lengths of nozzle inside and outside the vessel are 10mm and 40mm respectively and it is made up of seamless tube. The thickness of shell is 20mm. Internal pressure in the shell is 5MPa. The corrosion allowance is 2mm. Permissible tensile stress for shell and nozzle material is 200MPa. Design the dimensions of reinforcing pad if required. The reinforcing material is of same quality as that of the shell and is available in thickness of 18mm. (Assume weld efficiency as 90%)

- Log in to post comments