Question and answers

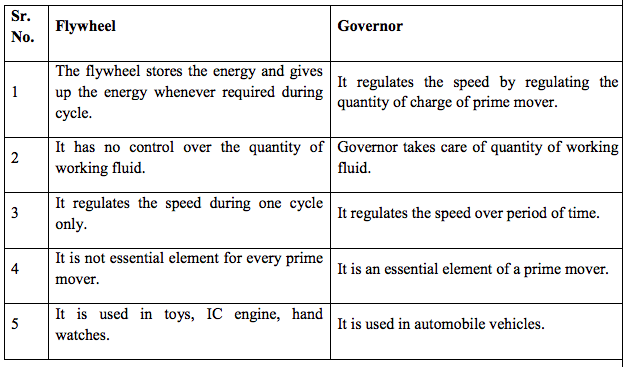

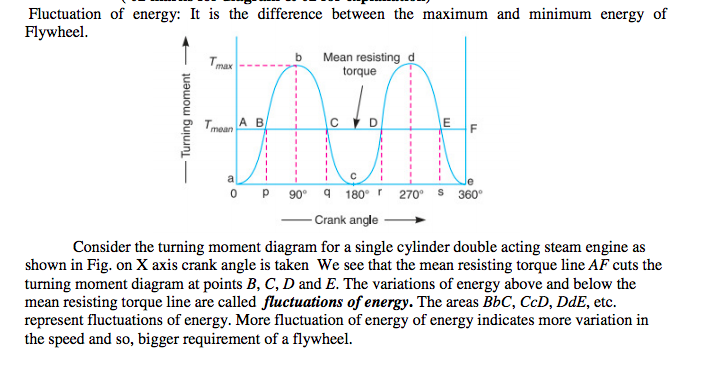

| Que.No | Marks | |

|---|---|---|

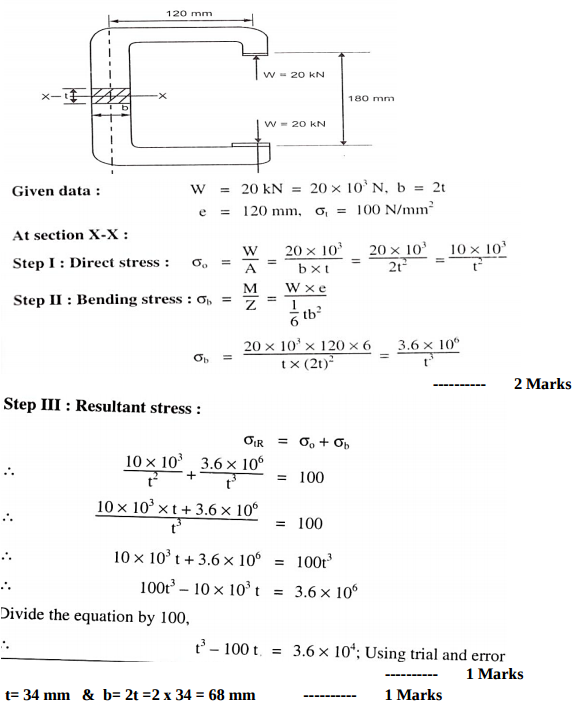

| Q 2 a ) |

8 |

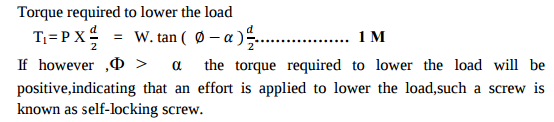

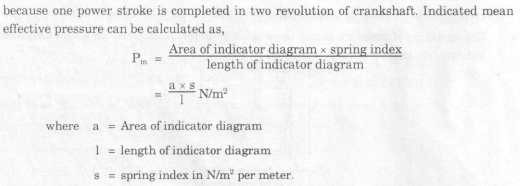

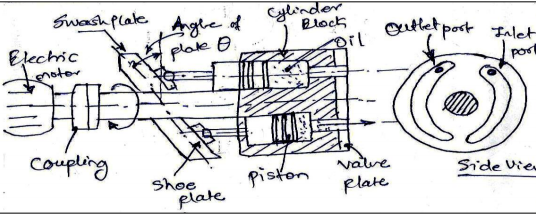

Question:What is swash plate? What is its use? What will happen if we change the angle of swash plate? Explain with sketchAnswer: It’s an inclined plate in axial piston pump on which all pistons are connected through piston rod. This swash plate is usually inclined. Use – It is helps to reciprocate the piston of axial piston pump while the cylinder block is rotating Working: Motor drives the shaft, which in turn rotates the entire cylinder block. The pistons are connected to inclined swash plate through piston rod. Now since swash plate is inclined and block is rotating, the piston reciprocates inside the barrel. The reciprocating motion of piston causes suction and delivery of fluid through inlet and outlet ports which come infront of outlet of piston. If we change the angle of swash plate i.e. θ if a) θ = 0 then no flow of oil, because pistons are at same level. When θ = 0 swash plate is vertical. No reciprocation of piston, hence no flow. b) θ = max or +ve, then x will be stroke length which is maximum and there will be maximum forward flow. c) θ = -ve, then ‘x’ i.e. stroke length will be maximum in reverse direction and hence there will be reverse flow. By changing the swash plate angle we can vary the stroke length of the piston. and also output flow can be changed.

|

| Q 2 a ) |

8 |

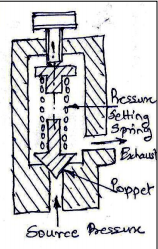

Question:Why pressure relief valve is used in hydraulic circuit? Explain in details with neat sketchesAnswer: Pressure Relief Valve used because; 1. To Maintain desired pressure levels in the circuit. 2. To set maximum pressure in hydraulic system. 3. Protect the pump and other system components from overloading. 4. It acts as a relief and safety device ExplanationSimple pressure relief valve is also a Direct operated pressure relief valve. It consists of Poppet, spring, pressure setting knob and valve body. It is normally closed valve connected between pressure line and the oil reservoir when inlet oil pressure is less than the spring force; it means that it is insufficient to overcome the spring force, the valve remains closed. The pressure of oil is safe for the system. When the oil pressure is greater than spring force, it pushes the poppet against the spring force and unseated the poppet. Now the valve opens and oil flow from inlet port to the reservoir. The valve will remain open until the excessive pressure is diverted to the tank. Cracking pressure: the pressure at which the valve first opens is called the cracking pressure. It is essential for every hydraulic system to provide pressure relief valve as a safeguard against the pressure.

|

| Q 2 b ) |

8 |

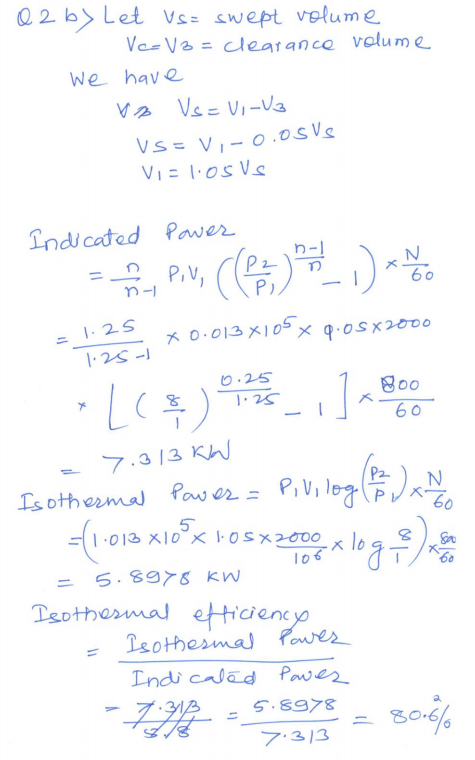

Question:A single stage reciprocating air compressor has a swept volume of 2000 cm3 and runs at 800 rpm. It operates on a pressure ratio of 8 with a clearance 5% of the swept volume. Assume NTP room conditions at inlet (p = 101.3 kPa t = 15°C) and polytropic compression and expansion with n = 1.25 calculate i) Indicated power, ii) Volumetric efficiency, iii) Mass flow rate iv) Isothermal efficiencyAnswer:

|

| Q 2 b ) |

8 |

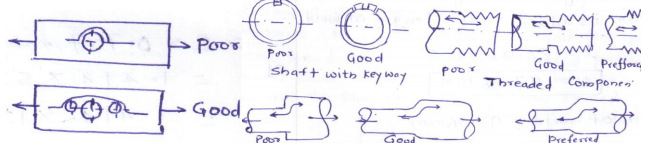

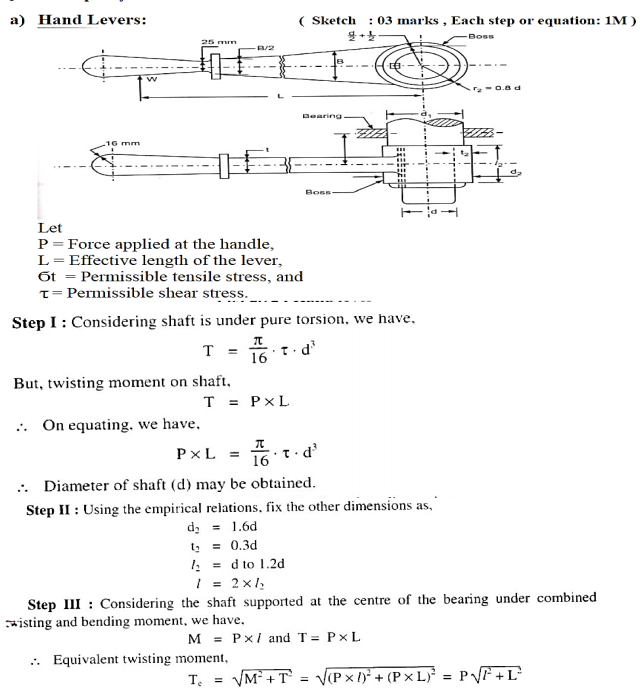

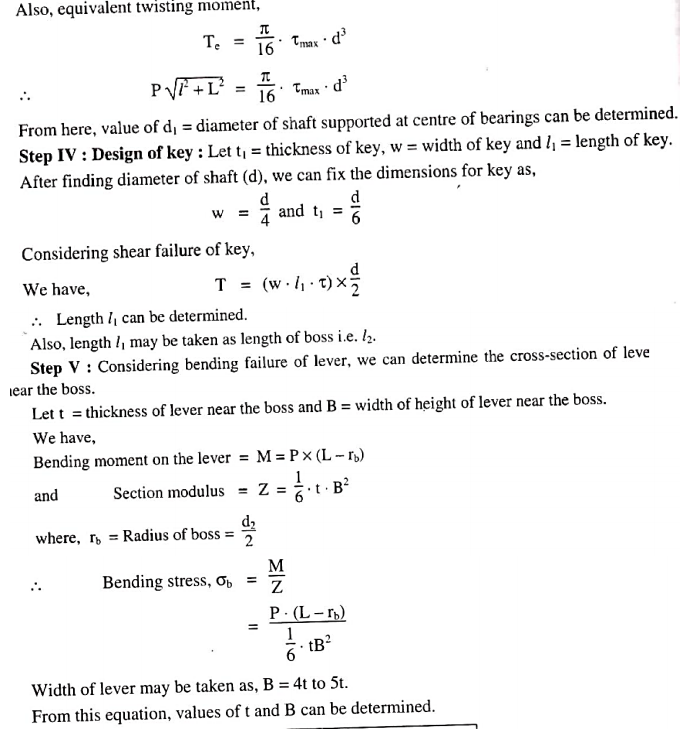

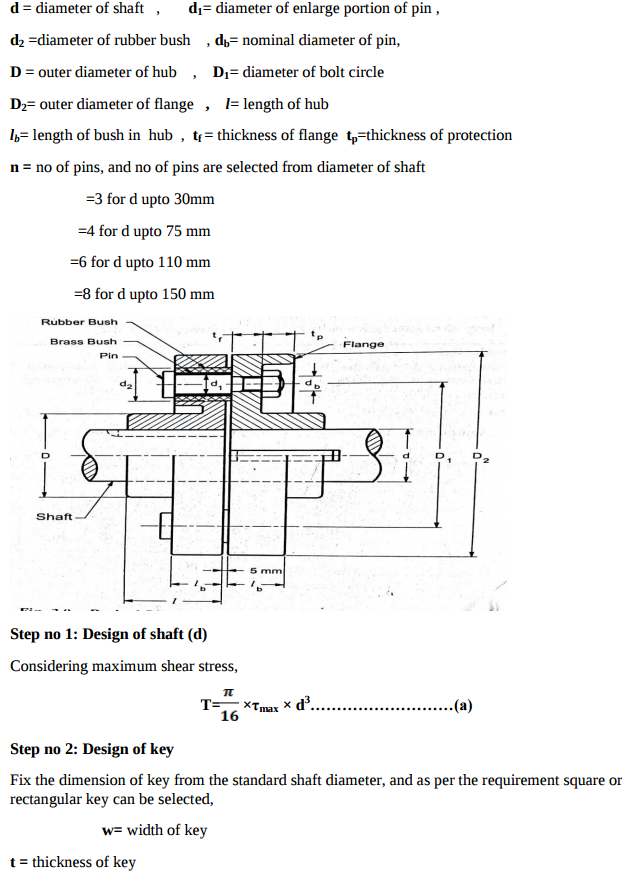

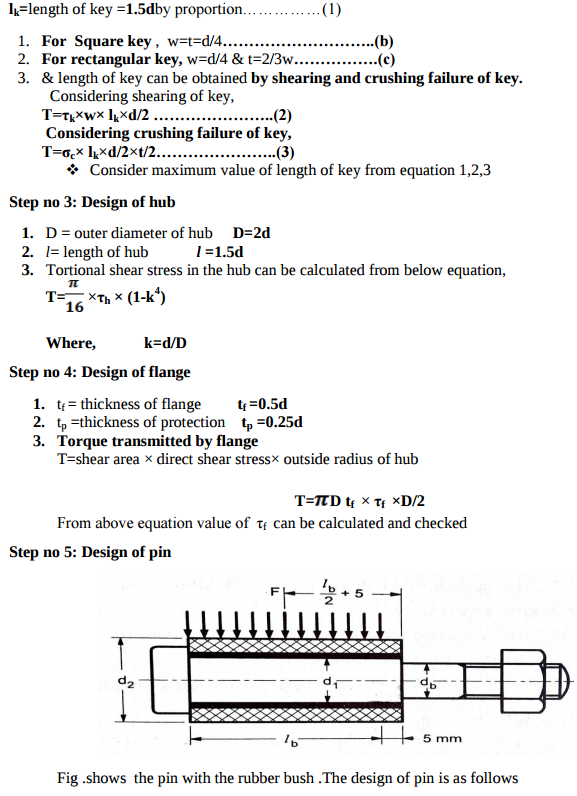

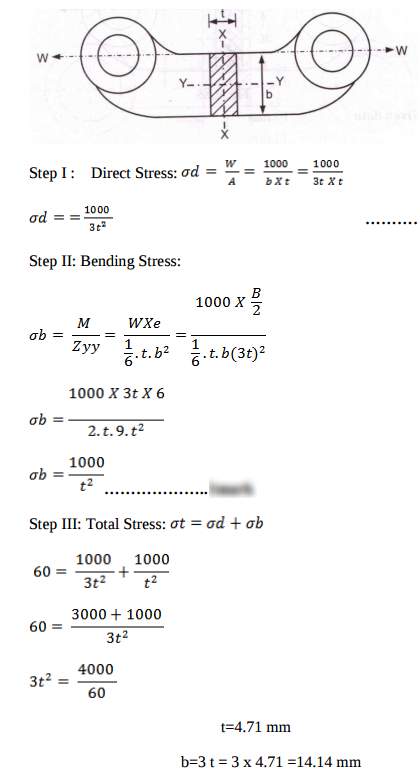

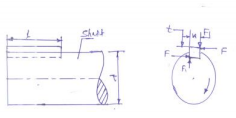

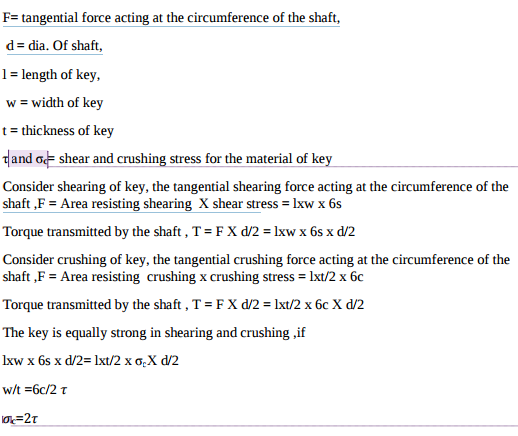

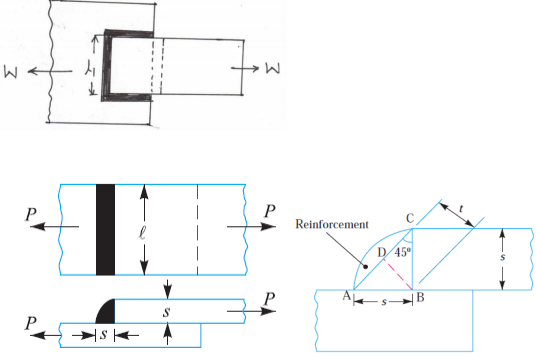

Question:Explain with the help of neat sketches, the design procedure of a square sunk keyAnswer:

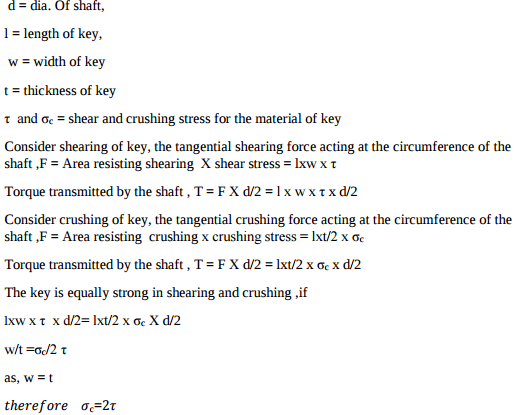

T= Torque transmitted by the shaft , F= tangential force acting at the circumference of the shaft,

|

| Q 2 b ) |

4 |

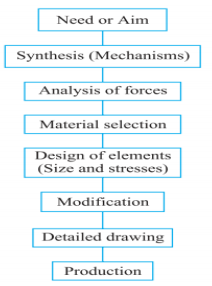

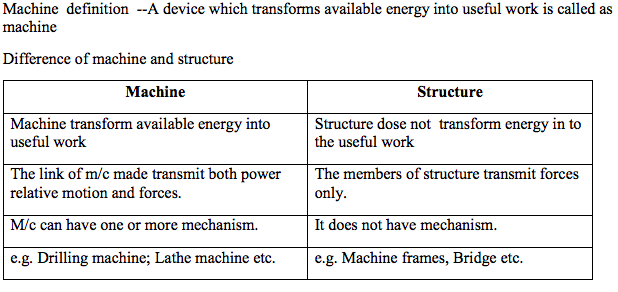

Question:What is machine ? Differentiate between a machine and a structure.Answer:

|

| Q 2 c ) |

8 |

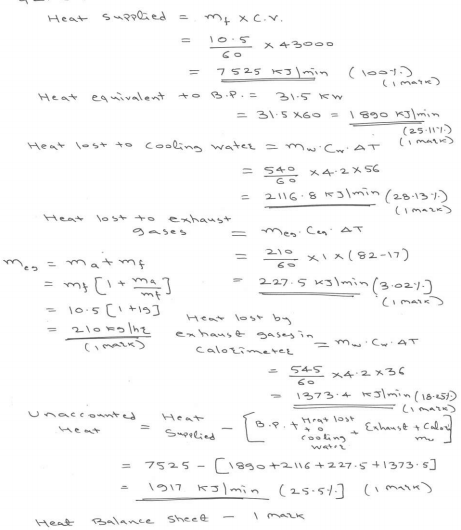

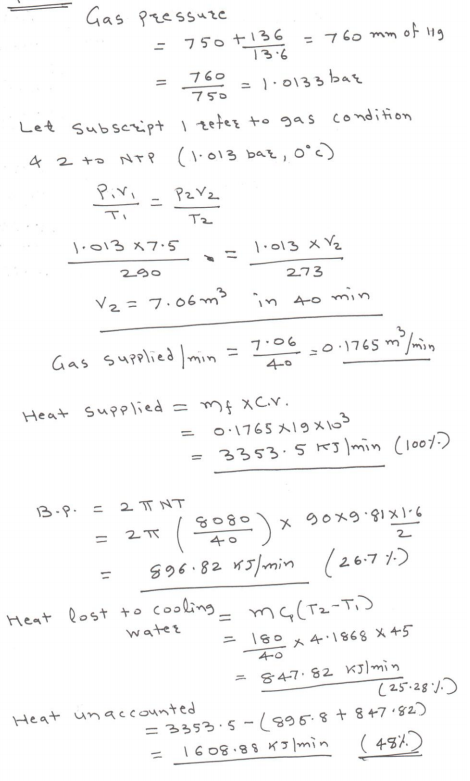

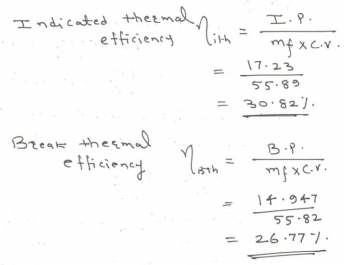

Question:A four stroke gas engine has a cylinder diameter of 25 cm and stroke 45 cm. The effective diameter of brake is 1.6 m. The observations made in a test of the engine were as follows. Duration of test = 40 min. Total no. of revolutions = 8080 Total no. of explosions = 3230 Net load on brake = 90 kg Mean effective pressure = 5.8 bar Volume of gas used = 7.5 m3 Pressure of gas = 136 mm of water Atm. temp. = 17°C Calorific value of gas = 19 MJ/m3 at NTP Rise in temp. of jacket cooling water = 45°C Cooling water supplied = 180 kg Draw heat balance sheet and estimate indicated thermal efficiency and brake thermal efficiency. Assume atmospheric pr. as 760 mm of Hg.Answer:

|

| Q 2 c ) |

4 |

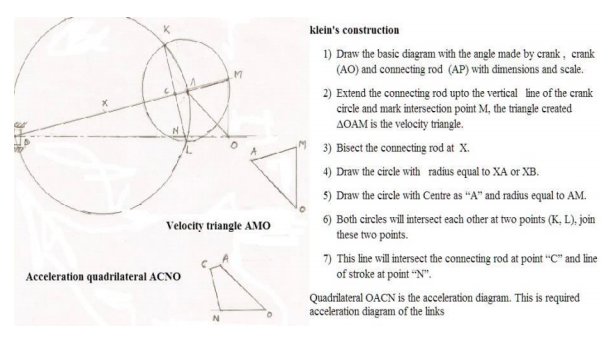

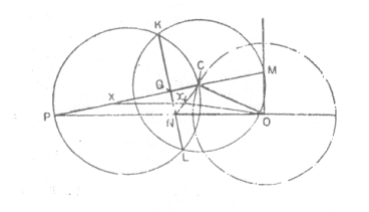

Question:Explain Klein’s construction to determine velocity and acceleration of different links in single slider crank mechanism.Answer: Klein’s construction a) For velocity of different links b) For acceleration of different links

|

| Q 2 c ) |

8 |

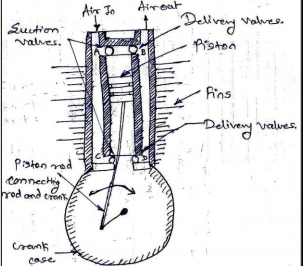

Question:Explain the construction and working of doubled acting reciprocating compressor with neat sketch.Answer: Double acting reciprocating air compressor is similar to double acting reciprocating pump. It is comprised of following parts: 1) Cylinder 2) Piston and piston rod and connecting rod. 3) Crank and crank case 4) Two suction valves and two delivery valves. 5) One inlet port and one outlet port It uses four bar mechanism. There are 4 valves (2 suction valves and 2 delivery valves) shown at A, B, C, D in figure. There are cooling fans similar to single acting compressors. The crank rotates on electric motor/engine/turbine. In this compressor, compression of air takes place on both side of the piston. When crank rotates, the piston starts reciprocating. When piston comes down and attains, ‘Bottom dead center piston’ the air comes in through port ‘A’ due to vacuum created due to downward movement. When piston starts moving upward, the air starts compressing. When piston attains, ‘Top dead center piston’, the stroke is complete and air is fully compressed which goes out through delivery valve ‘B’ to air receiver. During this upward movement the vacuum is created on other side (Piston rod side) of piston. Suction valve ‘C’ opens and air comes in. When piston starting comes down, this air which came through valve ‘C’, gets compressed and compressed air goes out through delivery valve ‘D’ to air receiver. In this downward movement air comes in through valve ‘A’ and entire cycle repeats.

|

| Q 2c)(i) |

8 |

Question:State applications of maximum shear stress theory and principal normal stress theoryAnswer: (i) Applications of maximum shear stress theory : for ductile material , crank shaft, propeller shafts , c frames (ii) Applications of maximum principle normal stress theory : for brittle material , machine spindle, machine beds , c frames, overhang crank ----------------------------------------------------------------------------------------------------- |

| Q 2c)(ii) |

8 |

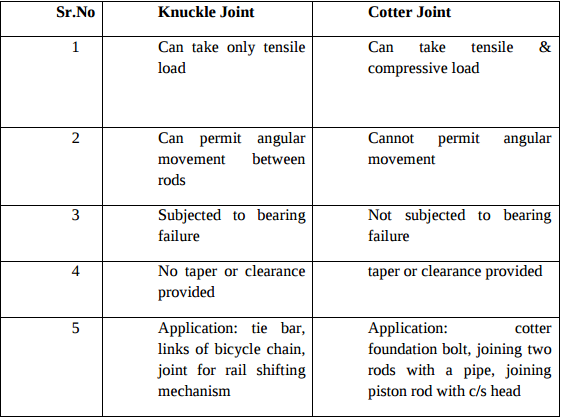

Question:State two applications each of cotter joint and knuckle joint.Answer: Applications of cotter joint: cotter foundation bolt, big end of the connecting rod of a steam engine, joining piston rod with cross head, joining two rods with a pipe Applications of knuckle joint: link of bicycle chain, tie bar of roof truss, link of suspension bridge, valve mechanism, fulcrum of lever, joint for rail shifting mechanism ----------------------------------------------------------------------------------------------------- |

| Q 2 d ) |

4 |

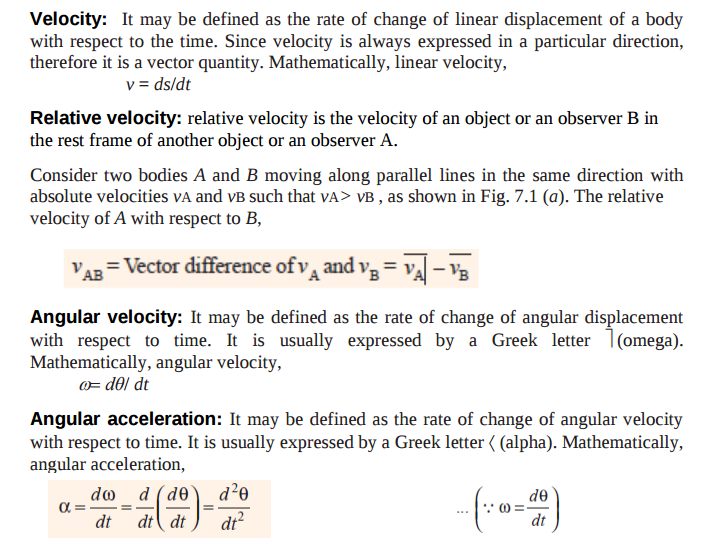

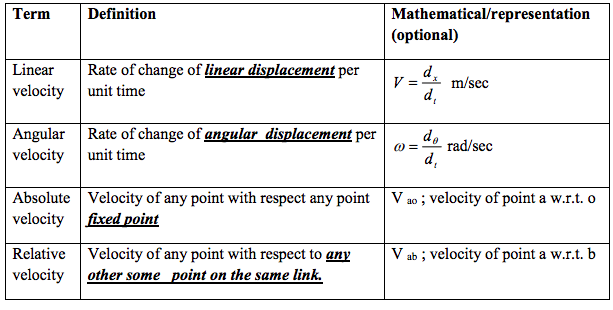

Question:Define the terms: (i) Linear velocity (ii) Angular velocity (iii) Absolute velocity (iv) Relative velocityAnswer:

|

| Q 2 d ) |

4 |

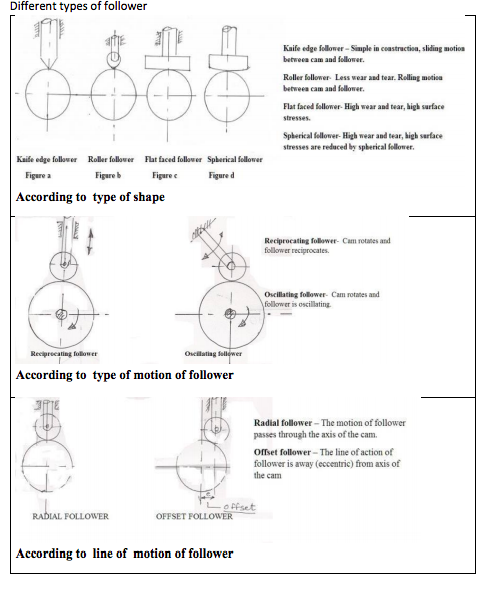

Question:Explain with neat sketch different types of follower.Answer:

|

| Q 2 f ) |

4 |

Question:A pulley is driven by the flat belt running at speed of 600m/min. and transmit 4 kW. The coefficient of friction between belt and pulley is 0.3 and angle of lap is 160°. Find maximum tension in the belt.Answer: Flat belt speed = V = 600 m/min = 600/60 m/sec = 10 m/sec; Power transmitted = P = 4 kW ; Coefficient of friction =µ = 0.3; Angle of lap = θ =1600 Belt tension ratio = T1/ T2 = eµθ = e 0.3(160x π/180) = 2.31; T1/ T2 = 2.31; T1= T2 x 2.311--------------------------------(1) P = ( T1 - T2) x V ; --------------------------------(2) P = ( T2 x 2.31- T2)x 10; Putting value of power P = 4 kW 4 x1000 = ( T2 x 2.31 - T2)x 10; T2 = 305.34 N T1 = 705.34N ----------------------------------------------------------------------------------------------------- |

| Q 3 a ) |

4 |

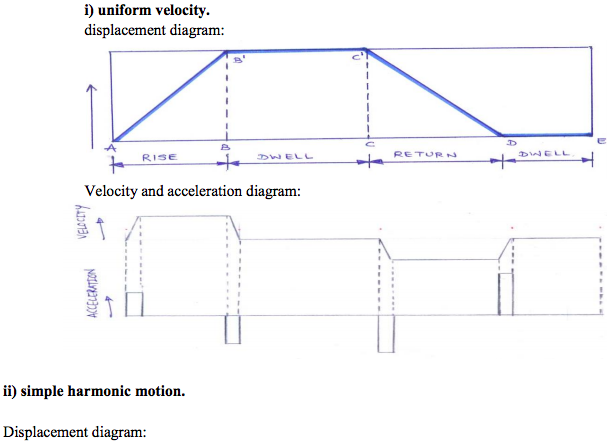

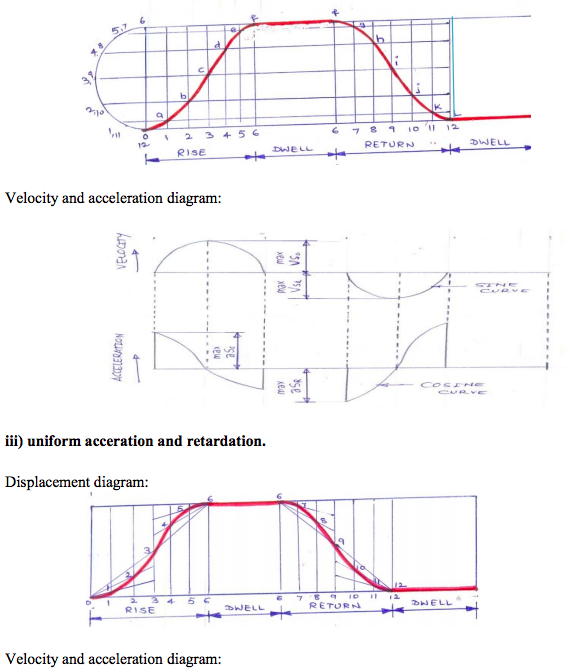

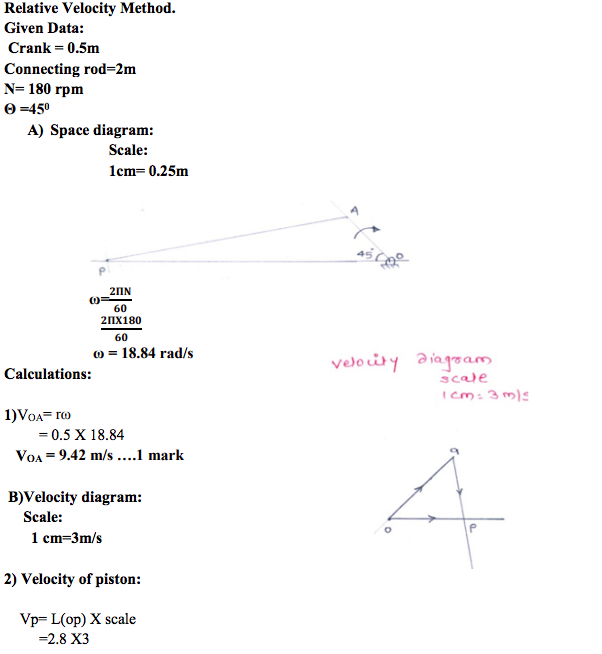

Question:Discuss the following motion of the follower by drawing the displacement velocity and acceleration diagram. (i) Uniform Velocity (ii) Simple Harmonic Motion (iii) Uniform acceleration and retardationAnswer:

|

| Q 3 a ) |

4 |

Question:List any four pollutants in exhaust gases of I.C. engine with their effects.Answer: The major air pollutants emitted by petrol & diesel engines are CO2, CO, HC, NOx, SO2, smoke & lead vapour. Effect of CO: Carbon monoxide combines with hemoglobin forming carboy hemoglobin ,which reduces oxygen carrying capacity of blood. This leads to laziness, exhaustion of body & headache. Prolong exposure can even leads to death. It also affects cardiovascular system, thereby causing heart problem Effect of CO2: Causes respiratory disorder & suffocation. Effect of NOx: It causes respiration irritation, headache, bronchitis, pulmonary emphysema, impairment of lungs, and loss of appetite & corrosion of teeth to human body. Effect of HC: • It has effect like reduced visibility, eye irritation, peculiar odour & damage to vegetation & acceleration the cracking of rubber products. • It induce cancer, affect DNA & cell growth are know a carcinogens. Effect of SO2: It is toxic & corrosive gas, human respiratory track of animals, plants & crops. ----------------------------------------------------------------------------------------------------- |

| Q 3 a ) |

4 |

Question:State the composition of the materials 30 Ni 16 Cr5, 40C8, FeE230 X15Cr25Ni 12Answer: 30 Ni 16 Cr5 : alloy steel carbon 0.3% of average, Nickel 16%, chromium 5% 40C8 : Plain carbon steel carbon 0.4% of average, manganese 0.8% FeE230 : Steel with yield strength of 230N/mm2 X15Cr25Ni12 : high alloy steel carbon 0.15% of average, chromium 25%, Nickel 12%, ----------------------------------------------------------------------------------------------------- |

| Q 3 a ) |

4 |

Question:Write any four advantages of oil hydraulic system.Answer: We can generate very high pressures in hydraulic system. Due to this nature of hydraulic system we can use this power to lift, hold, press very heavy loads 2) Weight to power ratio of a hydraulic system is comparatively less than that of an Electro-Mechanical System. Electric motor weigh appropriately 8.5 Kg/kW whereas, same power hydraulic motor weighs 0.85 kg/kW only. 3) The speed control of linear as well as rotary actuators can be achieved with ease. By merely adjusting small flow control valve, wide range of speed and feed can be obtained. 4) The system provides instant and smooth reversible motion ----------------------------------------------------------------------------------------------------- |

| Q 3 b ) |

4 |

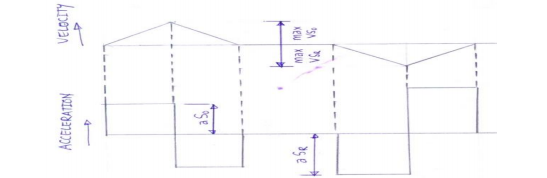

Question:Draw symbols of: (i) Oil reservoir (ii) Oil filter (iii) Heat exchanger (iv) Unidirectional fixed displacement pump.Answer:

|

| Q 3 b ) |

4 |

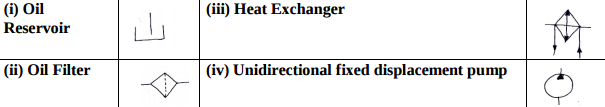

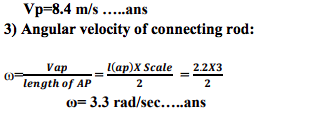

Question:The crank and connecting rod of steam engine are 0.5m and 2m long respectively. The crank makes 180r.p.m. in clockwise direction. When it has turned through 45° from I.D.C. Find the velocity of piston and angular velocity of connecting rod by relative velocity method.Answer:

|

| Q 3 b ) |

4 |

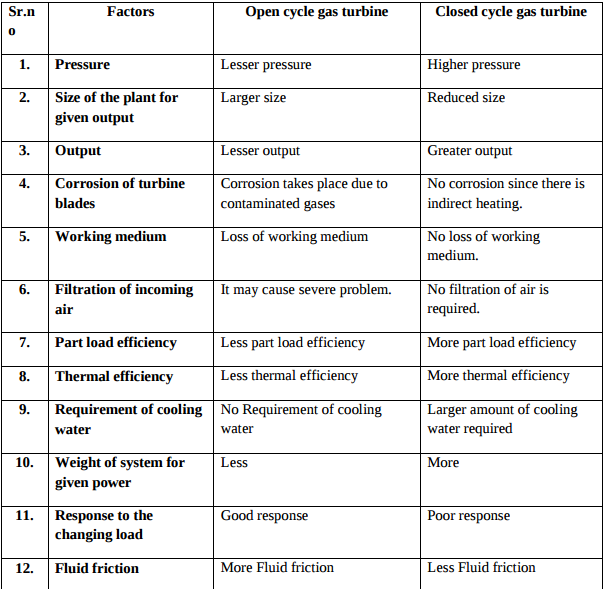

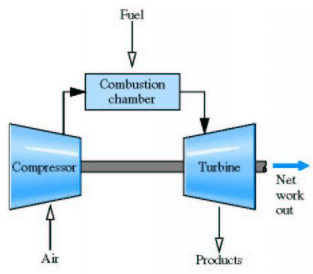

Question:Compare closed cycle and open cycle gas turbine.Answer: Open cycle and closed cycle gas turbines Any four differences

|

| Q 3 b ) |

4 |

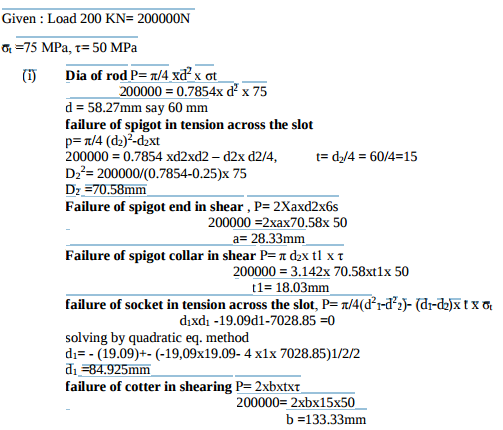

Question:Design single cotter joint to transmit 200 kN. Allowable stresses for the material are 75 MPa in tension and 50 MPa in shear.Answer:

|

| Q 3 c ) |

4 |

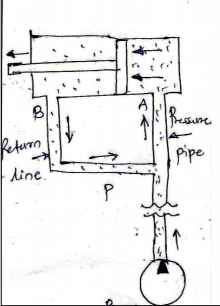

Question:Explain the principle of regenerative circuit.Answer: Principle of regenerative circuit is recovering the energy available with returning oil by using regeneration technique. The concept of re-generative circuit is explained from following figure. Consider the double acting cylinder. Pressurized oil from pump is admitting in cylinder cavity through port (A). Due to pressure force piston is moving from right to left. During this movement, the oil present on piston rod side of piston starts coming out through port (B). This oil will return to the oil reservoir via DC valve. It is clear from figure that, returning oil will enter in pressure pipe through pipe ‘P’ During exit of oil through port (B), some energy is still there with oil on piston rod side. This energy is otherwise wasted if this oil directly goes to oil reservoir. To avoid wastage of this energy, pipe ‘P’ is connected so that, the pressurized oil gets more energy and it will create more pressure force while entering through port (A).

|

| Q 3 c ) |

4 |

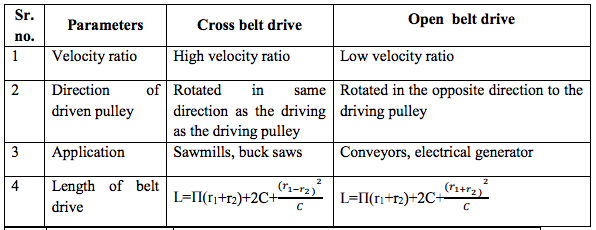

Question:Compare cross belt drive and open belt drive on the basis of - (i) Velocity ratio (ii) Direction of driven pulley (iii) Application (iv) Length of belt driveAnswer:

|

| Q 3 c ) |

4 |

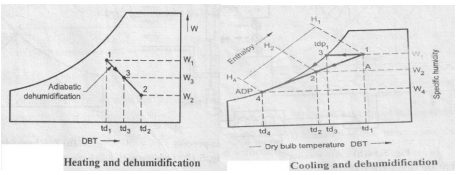

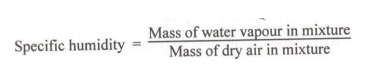

Question:Define i) Humidity ratio, ii) Specific humidityAnswer: Specific humidity : It is defined as the ratio of mass of vapor to the mass of dry air in a given sample of moist air . It is denoted by ω

|

| Q 3 c ) |

4 |

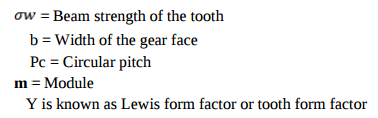

Question:State the ‘Lewis equation’ for spur gear design. State SI unit of each term in the equation.Answer: Lewis equation: WT = σw.b.π.m.y, WT= Tangential load acting at the tooth in N σw= bending stress in N/mm2 b= width of the gear face in mm m= module in mm y= lewis form factor. ----------------------------------------------------------------------------------------------------- |

| Q 3 d ) |

4 |

Question:What is FRL unit? Explain its functionAnswer: FRL unit means Filter Regulator and Lubricator Unit Function of FRL unit Filter (F) – 1) To remove the micron and sub-micron particles present in the entering air of compressor 2) Used to separate out contaminants like dust, dirt particles from the compressed air Regulator (R)–In pneumatic system the pressure of compressed air may not stable due to possibility of line fluctuation. Hence there is a need to maintain and regulate the air pressure. This function is performed by regulator. Lubricator (L) – Sliding components like spool, a pneumatic cylinder has sliding motion between parts. It may cause friction and wear and tear at mating parts. To reduce friction, lubricating oil particles are added in the compressed air with the help of lubricator ----------------------------------------------------------------------------------------------------- |

| Q 3 d ) |

4 |

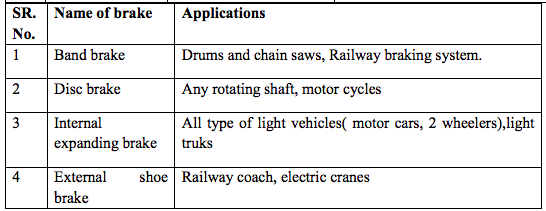

Question:State the applications of : (i) Band brake (ii) Disc brake (iii) Internal expanding shoe brake (iv) External shoe brakeAnswer:

|

| Q 3 d ) |

4 |

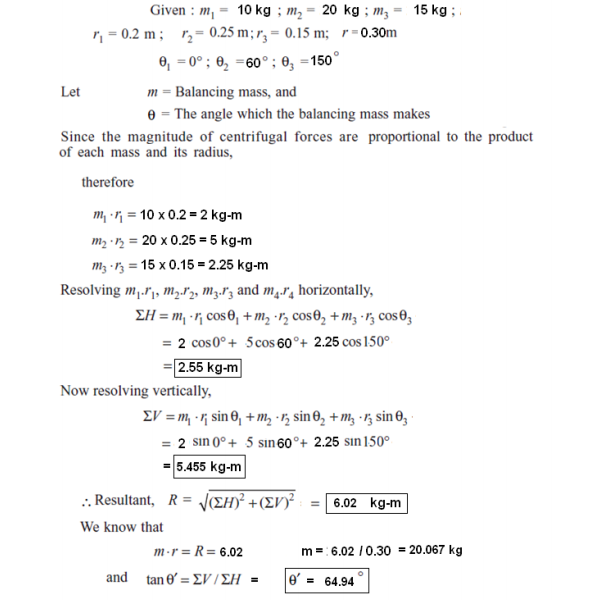

Question:Three masses 10 kg, 20 kg and 15kg are attached at a point at radii of 20 cm, 25cm and 15 cm respectively. If the angle between successive masses is 60° and 90°. Determine analytically the balancing mass to be attached at radius of 30cm.Answer: ----------------------------------------------------------------------------------------------------- |

| Q 3 d ) |

4 |

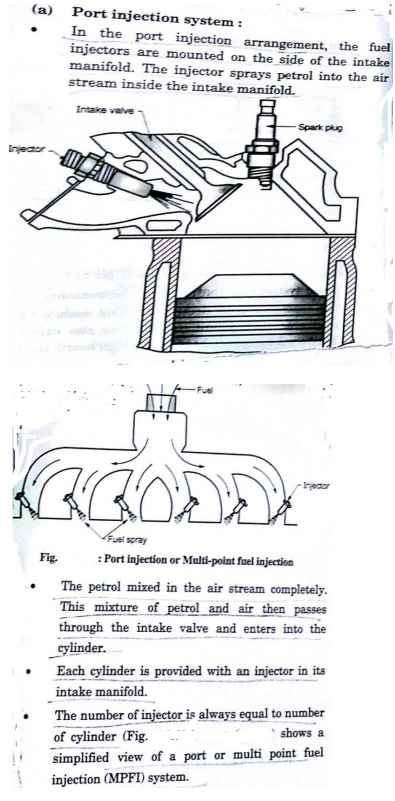

Question:Name four sensors used in I.C. engine and explain working of any one.Answer: Sensor used in IC engines ( Explanation of any one ) A sensor is an input device that provides variable information on an engine function. Examples of sensors include the airflow sensor (AFS), crank angle sensor (CAS), throttle potentiometer sensor (TPS) etc, and these provide data on load, rpm, temperature, throttle opening etc. This data is signaled to the ECM, which then analyses the results and computes an output signal. The output signal is used to actuate an n output device. Crank angle sensor: A permanent magnet inductive signal generator is mounted in close proximity to the flywheel, where it radiates a magnetic field. As the flywheel spins and the pins are rotated in the magnetic field, an alternating (AC) waveform is delivered to the ECM to indicate speed of rotation. If a pin is intentionally omitted at two points on the flywheel, or by contrast a double pin is used, the signal will vary at these points, and a reference to TDC will be returned to the ECM. The location of the positional signal is not at TDC, but may be some other point fixed by the VM. When used, the CAS provides the primary signal to initiate both ignition and fuelling. Air Flow Sensor (AFS): The AFS is normally located between the air filter and the throttle body. As air flows through the sensor, it deflects a vane (flap) which wipes a potentiometer resistance track and so varies the resistance of the track and generates a variable voltage signal. Manifold absolute pressure (MAP) sensor: The MAP sensor measures the manifold vacuum or pressure, and uses a transducer to convert the signal to an electrical signal which is returned to the ECM. The unit may be designed as an independent sensor that is located in the engine compartment or integral with the ECM. Coolant temperature sensor (CTS): The CTS is a two-wire thermistor that measures the coolant temperature. The CTS is immersed in the engine coolant, and contains a variable resistor that usually operates on the NTC principle. Throttle Position Sensor (TPS): TPS is provided to inform the ECM of idle position, deceleration, rate of acceleration and wide-open throttle (WOT) conditions. The TPS is a potentiometer which varies the resistance and voltage of the signal returned to the ECM. 01 03 MAHARASHTRA STATE BOARD OF TECH From the voltage returned, the ECM is able to calculate idle position, full-load and also how quickly the throttle is opened. Oxygen sensor (OS): An oxygen sensor is a ceramic device 'placed in the exhaust manifold on the engine side of the catalytic converter. The oxygen sensor returns a signal to the ECM, which can almost instantaneously (within 50 ms) adjust the injection duration. ----------------------------------------------------------------------------------------------------- |

| Q 3 d ) |

4 |

Question:Explain why bolts of uniform strength are preferred. Draw sketches of two different types of bolts of uniform strengthAnswer: bolts of uniform strength: if a shank dia.is reduced to a core dia.as shown in fig. the stress become same through out the length of the bolt. Hence impact energy is distributed uniformly throughout the bolt length, thus relieving the threaded portion of high stress. The bolt in this way becomes stronger and lighter. This type of bolt is known as bolt of uniform strength.Another method of obtaining the bolt of uniform strength is shown in fig.in this method, instead of reducing the shank dia.an axial hole is drilled through the head down to the threaded portion such that the cross sectional area of the shank becomes equal to the area of the threaded portion If bolts of uniform strength are not used a large portion of impact energy will be absorbed in the threaded portion and relatively a small portion of energy is absorbed by a shank. This uneven distribution of impact energy may lead to the fracture of the bolt in threaded portion .hence bolts of uniform strength are preferred.

----------------------------------------------------------------------------------------------------- |

| Q 3 e ) |

4 |

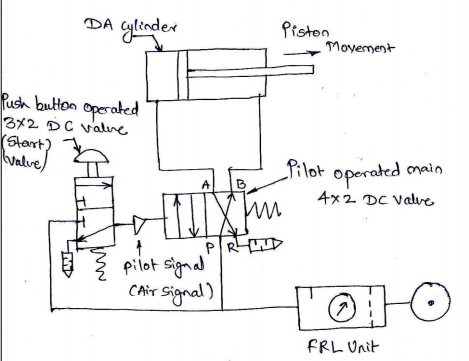

Question:Draw pilot operated DA cylinder circuit using 4 × 2 DC valve and 3 × 2 pilot valveAnswer:

|

| Q 3 e ) |

4 |

Question:What is scavenging in I.C. engine ? State its types.Answer: Scavenging : In two stroke engines , at the end of expansion stroke, combustion chamber is full of products of combustion. This is due to elimination of exhaust stroke like in four stroke engine. Scavenging is the process of clearing the cylinder after the expansion stroke. This is done short duration of time available between end of expansion and start of charging process. Types of scavenging : 1. Uniflow scavenging process 2. Cross scavenging process 3. Loop or reverse scavenging process ----------------------------------------------------------------------------------------------------- |

| Q 3 e ) |

4 |

Question:Prove that for a square key sc = 2t where sc = crushing stress t = shear stress.Answer:

|

| Q 3 f ) |

4 |

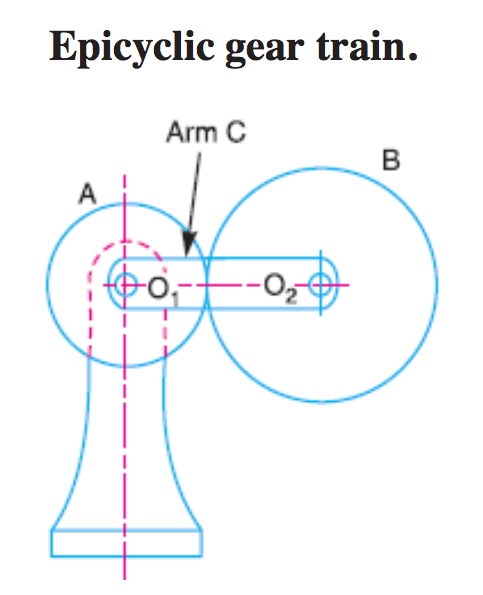

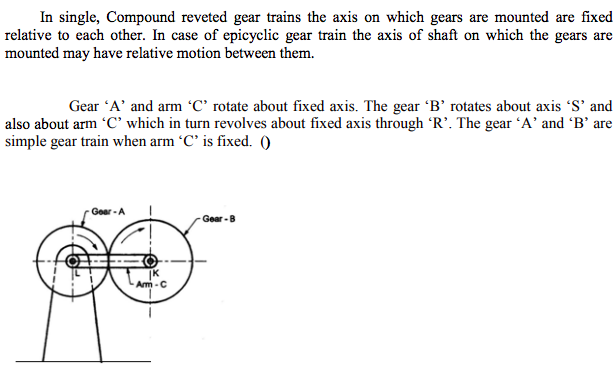

Question:Explain with neat sketch working principle of epicyclic gear train.Answer:

|

| Q 4 a ) |

4 |

Question:Generally, the lower side is kept “Tight side” and upper side is kept as “Slack side” with the belt drives having small driving pulley and big driven pulley. Why ?Answer: Power transmission in belt drive depends on angle of lap and frictional grip between belt and pulley. As slack side is at upper side angle of lap and grip increases. ----------------------------------------------------------------------------------------------------- |

| Q 4a)(a) |

4 |

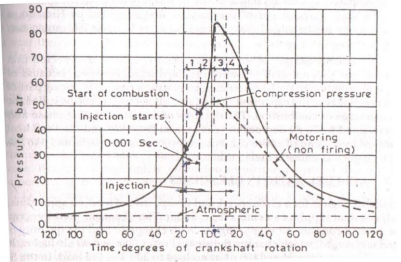

Question:Explain the process of combustion in diesel engine.Answer: Combustion in CI Engines :The combustion in CI engines is taking place in following stages as shown in figure 1. Ignition delay period: During this period, some fuel has been admitted but not yet ignited. The delay period is a sort of preparatory phase. It is counted from the start of injection to the point where P-ɵ curve separates from air compression curve. 2. Rapid or uncontrolled combustion : In this stage , the pressure rises rapid because during the delay period the fuel droplets have time to spray and have fresh air around them. This period is counted from end of delay period to the max pressure on indicator diagram. 3. Controlled combustion : uncontrolled combustion is followd by controlled combustion stage. The period of this stage assumed to be at the end of max cycle temperature. 4. After burning : It is expected to end combustion process after third stage. Because of poor distribution of fuel particles combustion still continues during remaining part of expansion stroke. This is after burning .

|

| Q 4a)(b) |

4 |

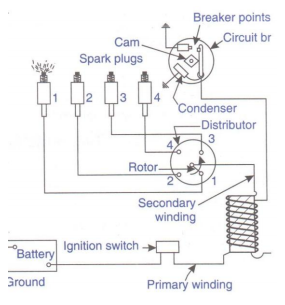

Question:Explain battery ignition in S.I. engine.Answer: Battery Ignition system : It consists of a battery of 6 or 12 volts, ignition switch, induction coil, condenser, distributor and a circuit breaker. One terminal of battery is ground to the frame of the engine and other is connected through the ignition switch to one primary terminal of the ignition coil . The other terminal is connected to one end of contact points of the circuit breaker. To start with the ignition switch is made on and the engine is cranked. The contacts touch, the current flows from battery through the switch. A condenser connected across the terminals of the contact breaker points prevent the sparking at these points. The rotating cam breaks open the contacts immediately and breaking of this primary circuit brings about a change in the magnetic fields and voltage changes from 12 to 12000 V. due to the high voltage. The spark jumps across the gap in the spark plug and air fuel mixture is ignited in the cylinder

|

| Q 4a)(c) |

4 |

Question:State the norms of Bharat stage III and IVAnswer: Bharat stage III and IV norms : Petrol Emission Norms (All figures in g/km) Emission Norm CO HC NOx HC+NOx PM BS-III 2.30 0.20 0.15 --- --- BS-IV 1.00 0.10 0.08 --- --- Diesel Emission Norms (All figures in g/km) Emission Norm CO HC NOx HC+NOx PM BS-III 0.64 --- 0.50 0.56 0.05 BS-IV 0.50 --- 0.25 0.30 0.025 CO emissions are Carbon Monoxide emissions are are more evident in Petrol engines. Long Term exposure can prevent oxygen transfer and increase headaches/nausea. HC emissions are Hydrocarbons which are again more prevalent in Petrol engines. Short term exposure can cause headaches, vomiting and disorientation. NOx emissions are Nitrogen Oxide emissions which are more prevalent in Diesel engines. Long Term exposure can cause Nose and eye irritation and damage lung tissue. PM is Particulate matter, again more prevalent in a Diesel engine. Long Term exposure can harm the respiratory tract and reduce lung function. ----------------------------------------------------------------------------------------------------- |

| Q 4a)(d) |

4 |

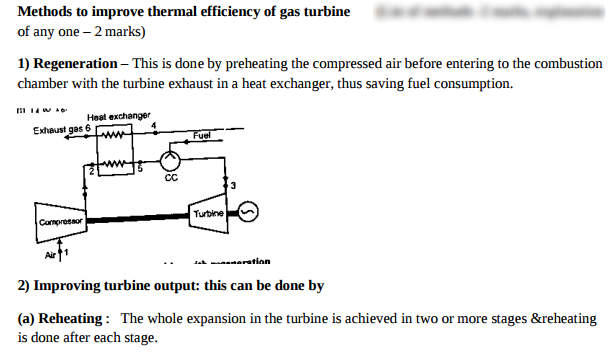

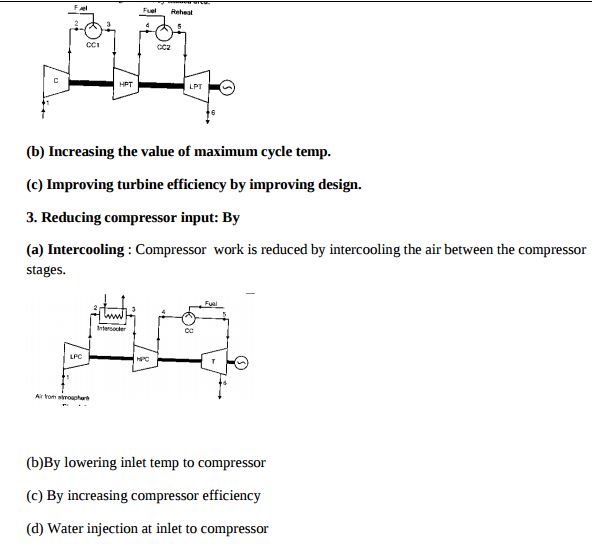

Question:State different methods for improving thermal efficiency of gas turbine and explain any one.Answer:

|

| Q 4a)(i) |

4 |

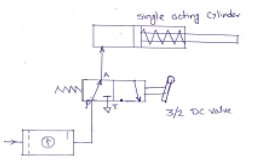

Question:What is the use of direction control valve? Explain with sketch.Answer: 1. DC valves are used to release, stop or redirect the fluid that flows through it. 2. DCV is used to control the direction of fluid flow in any hydraulic system and changing the position of internal movable parts. 3. To start, stop, accelerate, decelerate and change the direction of motion of a hydraulic actuator. 4. To permit the free flow from the pump to the reservoir at low pressure when the pump’s delivery is not needed into the system. 5. To vent the relief valve by either electrical or mechanical control. 6. To isolate certain branch of a circuit. The following circuit shows use of 3/2 DC valve. When the lever is operated, port A is connected to exhaust port ,i.e change in direction of the piston. (Alternative sketch can be considered)

|

| Q 4a)(i) |

4 |

Question:State four examples of ergonomic considerations in the design of a lathe machine.Answer: Ergonomics consideration in the design of Lathe machine Any 4 1) The controls on lathe should be easily accessible and properly positioned. 2) the control operation should involve minimum motions. 3) Height of lathe should be match with worker for operation 4)Lathe machine should make less noise during operation. 5) force& power capacity required in turning the wheel as per operation or human being can apply normally. 6) should get required accuracy in operation. ----------------------------------------------------------------------------------------------------- |

| Q 4a)(ii) |

4 |

Question:Draw bleed off circuit and label itAnswer:

|

| Q 4a)(ii) |

4 |

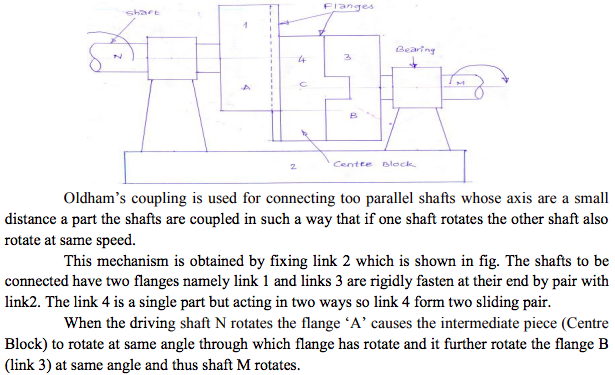

Question:Write the equation with Wahl’s factor, used for design of helical coil spring. State the SI unit of each term in the equationAnswer:

|

| Q 4a)(iii) |

4 |

Question:State four important modes of gear failure.Answer: Modes of Gear Failure: ANY 4 modes 1. Bending failure. Every gear tooth acts as a cantilever. If the total repetitive dynamic load acting on the gear tooth is greater than the beam strength of the gear tooth, then the gear tooth will fail in bending, 2. Pitting. It is the surface fatigue failure which occurs due to many repetition of Hertz contactstresses. 3. Scoring. The excessive heat is generated when there is an excessive surface pressure, high speed or supply of lubricant fails. 4. Abrasive wear. The foreign particles in the lubricants such as dirt, dust or burr enter betweenthe tooth and damage the form of tooth. 5. Corrosive wear. The corrosion of the tooth surfaces is mainly caused due to the presence ofcorrosive elements such as additives present in the lubricating oils ----------------------------------------------------------------------------------------------------- |

| Q 4a)(iii) |

4 |

Question:What are the limitations of pneumatic system?Answer: 1. Relatively low accuracy: As pneumatic systems are powered by the force provided by compressed air, their operation is subject to the volume of the compressed air. As the volume of air may change when compressed or heated, the supply of air to the system may not be accurate, causing a decrease in the overall accuracy of the system. 2. Low loading: As the cylinders of pneumatic components are not very large, a pneumatic system cannot drive loads that are too heavy. 3. Processing required before use Compressed air must be processed before use to ensure the absence of water vapour or dust. Otherwise, the moving parts of the pneumatic components may wear out quickly due to friction. 4. Uneven moving speed: As air can easily be compressed, the moving speeds of the pistons are relatively uneven. 5. Noise: Noise will be produced when compressed air is released from the pneumatic components. 6. Lubricator: Lubricator is required to add lubricant oil to compressed air to reduce friction. ----------------------------------------------------------------------------------------------------- |

| Q 4a)(iv) |

4 |

Question:State four disadvantages of screwed joints.Answer: Four Disadvantages of screwed joints: 1) Screwed joints are weaker than welded joint 2) Screwed joints weakens( due to holes) the parts that are to be joined. 3) Stress concentration in the threaded portion of screw makes them weak. 4) Locking arrangement is required in case of vibrations ----------------------------------------------------------------------------------------------------- |

| Q 4a)(iv) |

4 |

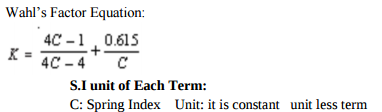

Question:Draw symbol of: 1) 2 × 2 DC valve 2) Fixed type flow control valve 3) Pressured relief valve. 4) MufflerAnswer:

|

| Q 4 b ) |

4 |

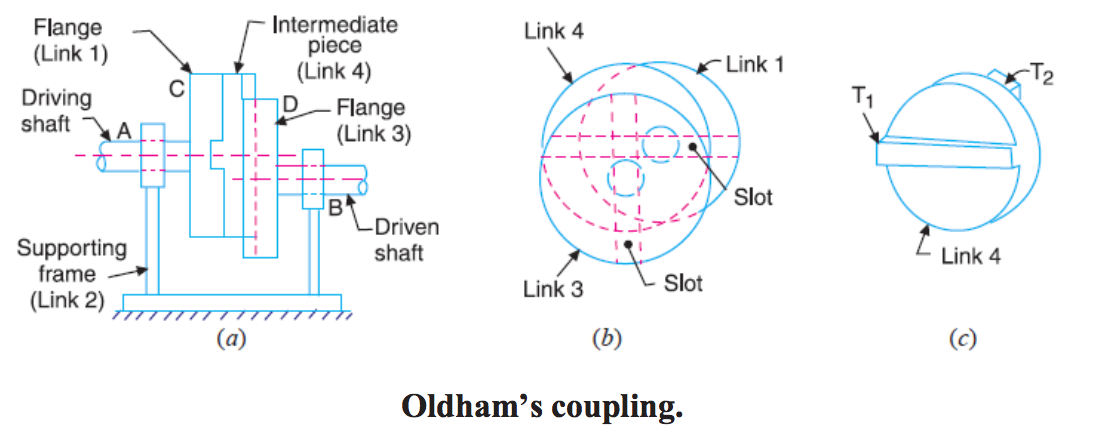

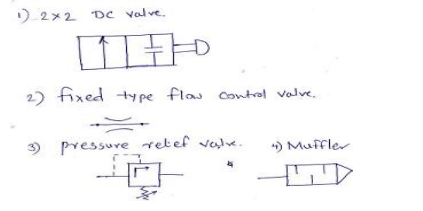

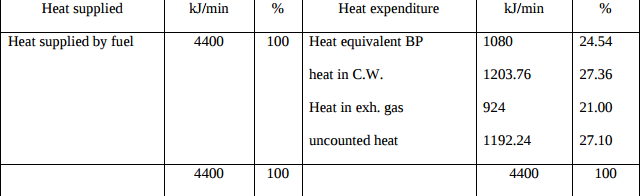

Question:Describe with neat sketch the working of Oldham’s coupling.Answer:

|

| Q 4b)(a) |

6 |

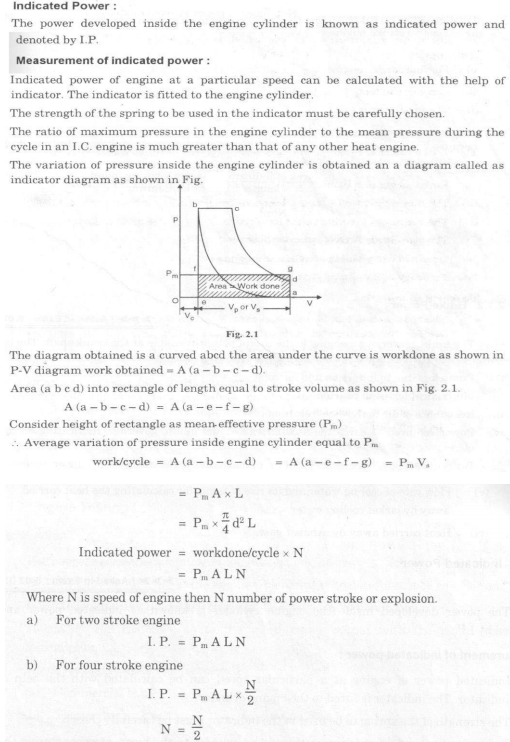

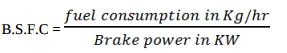

Question:Define – (i) Indicated power, (ii) Mechanical efficiency, (iii) BSFCAnswer: i) Indicated Power (ip) is defined as the power developed by combustion of fuel in the cylinder of engine. It is always more than brake power. ii) Mechanical efficiency : ηm : It is a measure of mechanical perfection of the engine or its ability to transmit power developed in the engine cylinder to the crank shaft . It is defined as the ratio of brake power to indicated power of the engine iii) B.S.F.C: It is the weight of fuel required to develop 1KW of the brake power for period of 1 hour. Unit of B.S.F.C is Kg/KW h. It is defined as the amount of fuel consumed per unit of break power developed per hour.

|

| Q 4b)(b) |

6 |

Question:List the additives of lubricant used in S.I engine and state their advantages.Answer: Additives (any six ) (1) Detergents – To keep engine parts, such as piston and piston rings, clean & free from deposits. (2) Dispersants – To suspend & disperse material that could form varnishes, sludge etc that clog the engine. (3) Anti – wear – To give added strength & prevent wear of heavily loaded surfaces such as crank shaft rods & main bearings. (4) Corrosion inhibitors – To fight the rust wear caused by acids moisture. Protect vital steel & iron parts from rust & corrosion. (5) Foam inhibitors – control bubble growth, break them up quickly to prevent frothing & allow the oil pump to circulate oil evenly. (6)Viscosity index improver – added to adjust the viscosity of oil. (7) Pour point depressant - improves an oil ability to flow at very low temperature ----------------------------------------------------------------------------------------------------- |

| Q 4b)(i) |

6 |

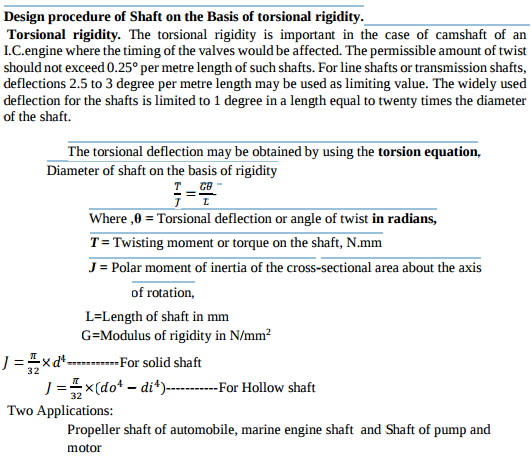

Question:Explain the design procedure of shaft on the basis of torsional rigidity. State the equation with SI units. State two applications of this approach.Answer:

|

| Q 4b)(i) |

6 |

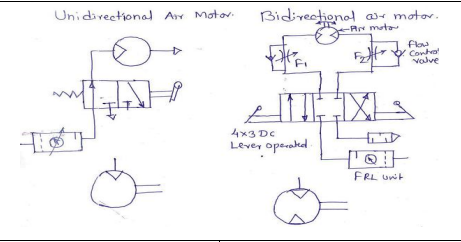

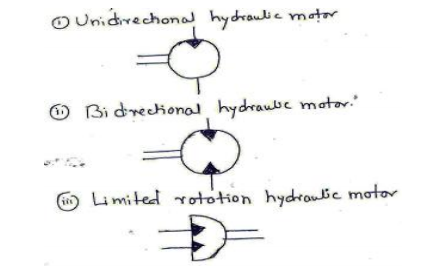

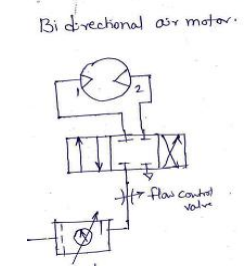

Question:What is the meaning of unidirectional air motor and bi directional air motor? Explain with sketch and draw symbol of bothAnswer: Operating or moving or allowing movement in one direction only. It runs in one direction only. It does not run in the other direction. Unidirectional motor can be operated by using 3/2 DC valve as shown in fig. Bidirectional air motor: Functioning or allowing movement in two usually opposite directions. It can runs in both direction. Bi-directional motor can be operated by using 4/3 DC valve as shown in fig

|

| Q 4b)(ii) |

6 |

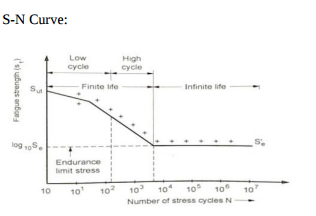

Question:Draw S-N curve. Explain the concept of endurance limit and its need in design of machine elementsAnswer:

Endurance Limit: It is defined as maximum value of the completely reversed bending stress which a polished standard specimen can withstand without failure, for infinite number of cycles (usually 107 cycles).It is known as endurance or fatigue limit (ϭe). Need of Endurance Limit in Machine Design: Endurance limit is used to describe a property of materials: the amplitude (or range) of cyclic stress that can be applied to the material without causing fatigue failure. ----------------------------------------------------------------------------------------------------- |

| Q 4b)(ii) |

6 |

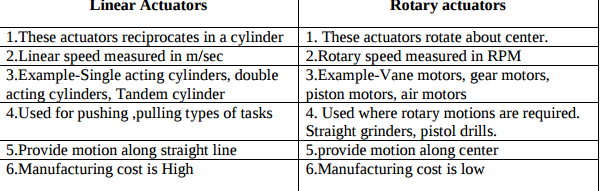

Question:Compare linear actuators and rotary actuators.Answer:

|

| Q 4 c ) |

4 |

Question:Distinguish between flywheel and governor.Answer:

|

| Q 4 d ) |

4 |

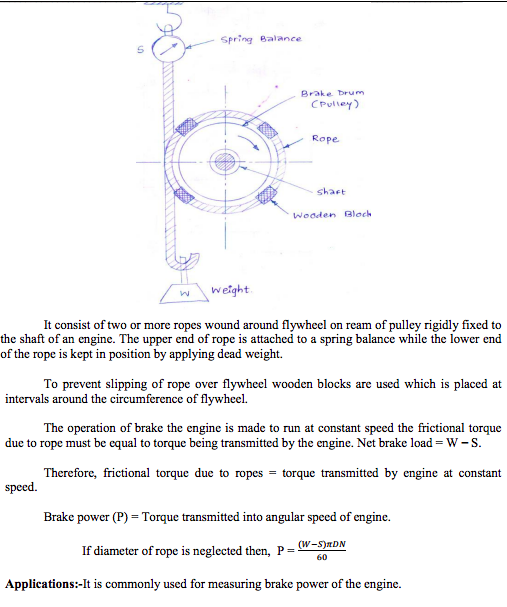

Question:Discuss the working of Rope brake dynamometer with the help of a neat sketch.Answer:

|

| Q 4 e ) |

4 |

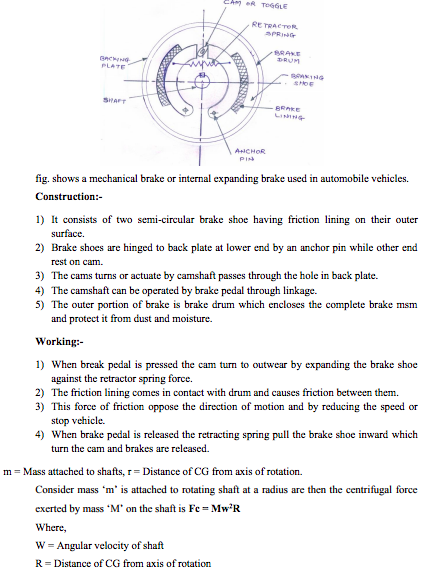

Question:Explain the working of internal expanding shoe brake with the help of neat sketch.Answer:

|

| Q 4 f ) |

4 |

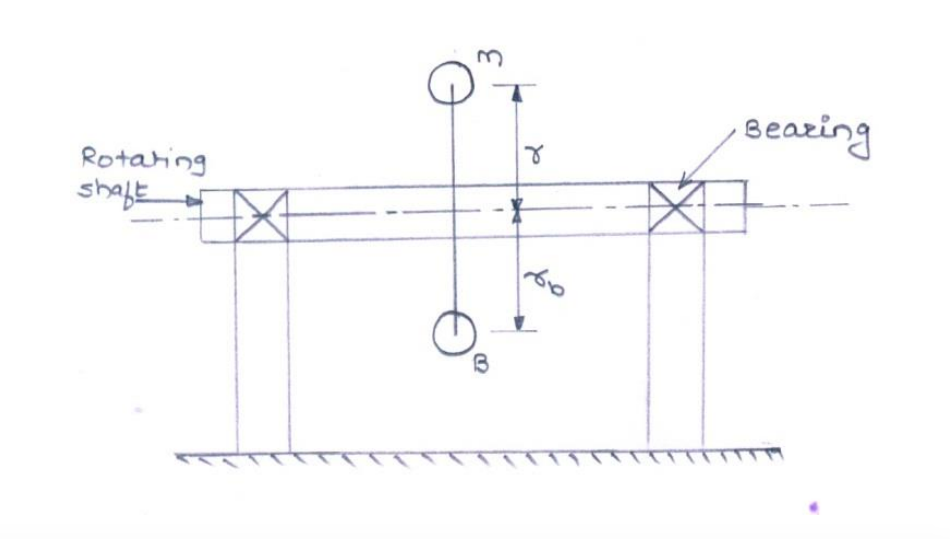

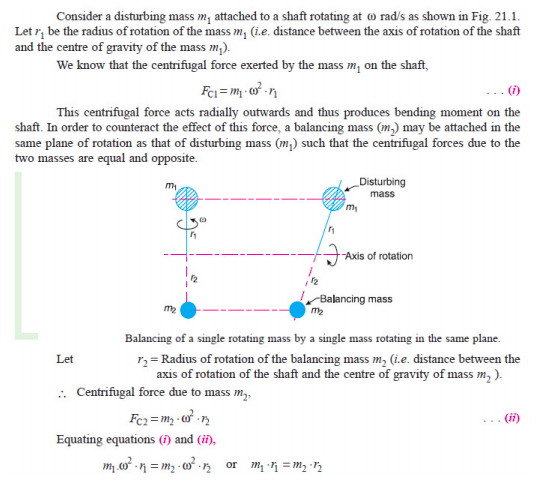

Question:Explain the process of balancing of single rotating mass by a single mass rotating in the same plane.Answer: m = Mass attached to shafts, r = Distance of CG from axis of rotation. Consider mass ‘m’ is attached to rotating shaft at a radius are then the centrifugal force exerted by mass ‘M’ on the shaft is Fc = Mw2R Where, W = Angular velocity of shaft R = Distance of CG from axis of rotation M = Mass attached to shaft.

Due to continuous rotation of shaft the centrifugal force developed will be continuously changing its direction. It will cause bending moment on shaft. To counter act the effect of centrifugal force the balance weight may be introduced in same plane of rotation. This balance weight should be attached it will result in exactly equal but opposite centrifugal force to that of disturbing weight ‘M’. The balanced centrifugal force is given by Fb = mbw2Rb For balancing the shaft – Mw2R = mbw2Rb.

----------------------------------------------------------------------------------------------------- |

| Q 5 a ) |

8 |

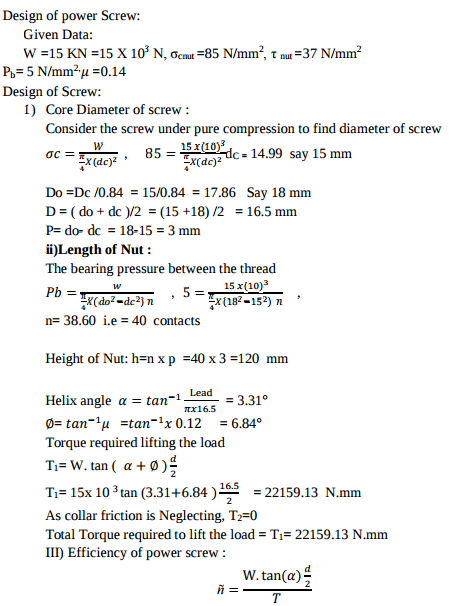

Question:A power screw on a machine has single start square thread with a non rotating bronze nut. Axial force on the screw is 15 kN. Allowable stresses for screw material in compression and shear are 85 MPa and 37 MPa respectively. Allowable bearing pressure for the screw nut pair is 5 MPa. Find (i) Core diameter of screw (ii) Length of the nut (iii) Efficiency of power screw in coefficient of friction between screw and nut is 0.12. (iv) Shear stresses in the threads of screw and nut.Answer:

|

| Q 5 a ) |

8 |

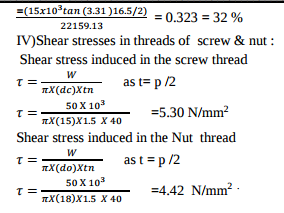

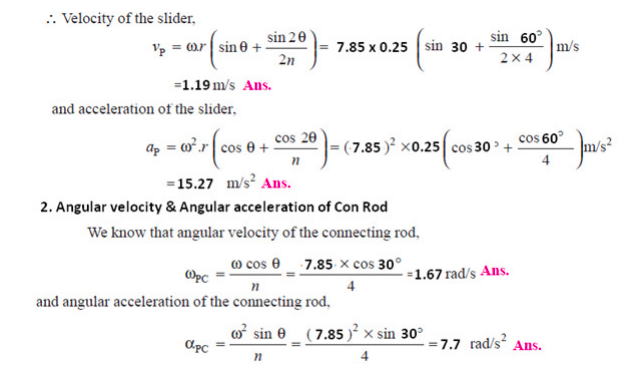

Question:In a slider crank mechanism the length of crank and connecting rod are 100mm and 40mm respectively. The crank rotates uniformly at 600 rpm clockwise. Then crank has turned through 45° from I.D.C. Find by analytical method. (i) Velocity and acceleration of slider (ii) Angular velocity and angular acceleration of connecting rod.Answer:

|

| Q 5 a ) |

8 |

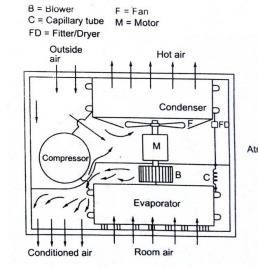

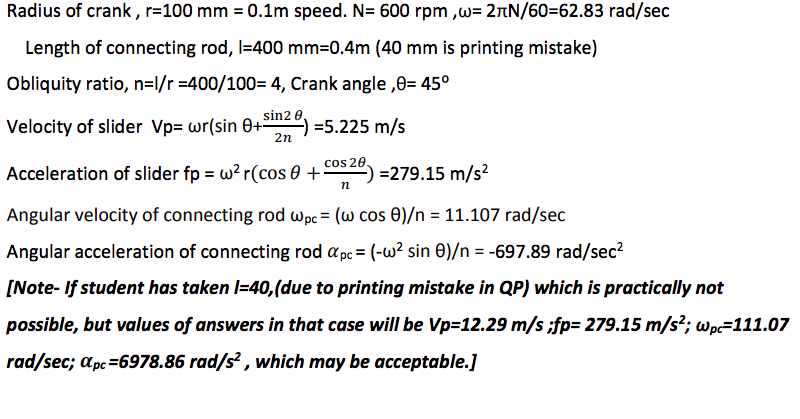

Question:Explain with neat sketch construction and working of ice plant.Answer: Working of Ice plant: The main cycle used for ice plant is vapor compression cycle with ammonia as the refrigerant in primary circuit and brine solution in secondary circuit. Brine solution takes heat from water in secondary circuit and delivers the heat to ammonia in primary circuit. Thus, the indirect method of cooling is used in ice plant. In secondary circuit brine is cooled in evaporator and then it is circulated around the can which contains water. The heat is extracted from the water in the can and is given to the brine. The brine is contentiously circulated around the can with the help of brine pump till entire water in the can is converted into ice at -6 0 C. Ammonia vapor coming out of evaporator is compressed to high pressure and then these vapors are condensed in the condenser. High pressure liquid ammonia is collected in the receiver and it is passed through the expansion valve to reduce its pressure and temperature as per requirement. The throttle liquid ammonia at low temperature & low pressure enters in evaporator, which are the coils dipped in brine tank. The liquid ammonia absorbs heat from brine and gets converted into vapors, which are drawn by suction line of compressor.

|

| Q 5a)(i) |

8 |

Question:Draw symbol of any three types of Hydraulic motors.Answer:

|

| Q 5a)(ii) |

8 |

Question:What is impulse circuit? ExplainAnswer: the main valve using the impulse of an impulse valve. As shown in fig. in circuit has two valves ; main valve and impulse valve. Main valve is a single pilot operated spring return type 4/2 direction control valve. Impulse valve is palm button operated spring return type 3/2 direction control valve. In normal position of valves, the double acting cylinder is in retracted position. When the palm button of impulsive valve is pressed manually, compressed air flows to the pilot port of main valve. Hence the speed of main valve will be shifted to the second position. Double acting cylinder is extends.

|

| Q 5 b ) |

8 |

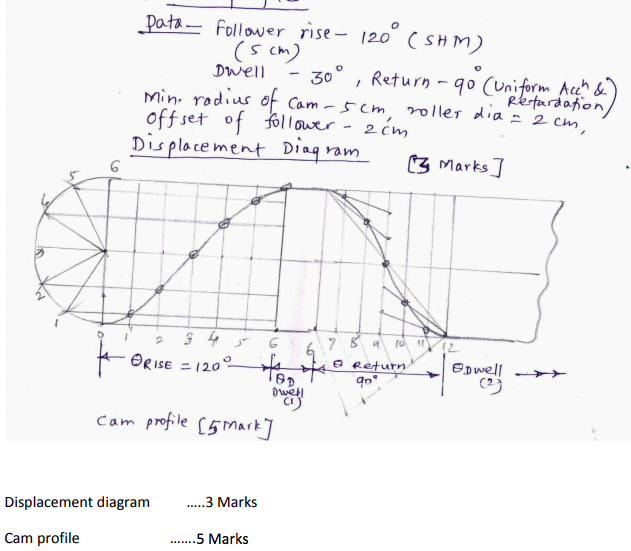

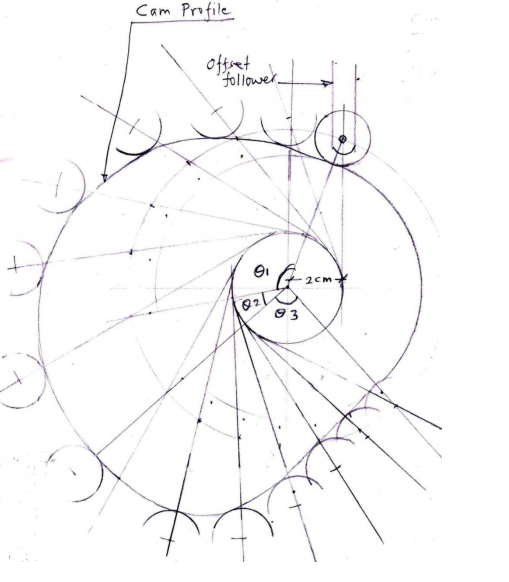

Question:Draw profile of cam to raise the valve with S.H.M. through 5cm in 120° of revolution, keep it fully raised through 30° and lower it with equal uniform acceleration and retardation through 90° of rotation. The valve remain closed during the rest of rotation. The diameter of the roller is 2 cm and the minimum radius of the cam is 5cm. The axis of the valve rod is offset 2cm from the axis of the shaft. Assume the cam rotating in clockwise direction.Answer:

----------------------------------------------------------------------------------------------------- |

| Q 5 b ) |

8 |

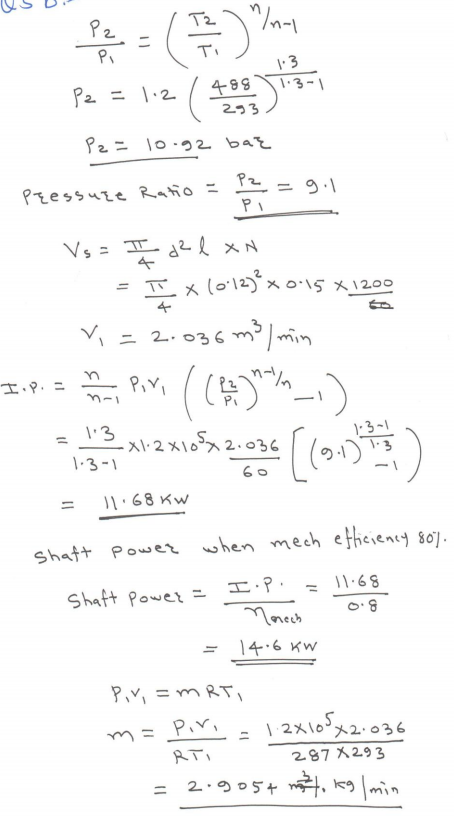

Question:A single cylinder reciprocating compressor has a bore of 120 mm and a stroke of 150 mm. and is driven at a speed of 1200 rpm. It is compressing CO2 gas from a pressure of 120 Kpa and temp. of 20°C to a temp. of 215°C. Assuming polytropic compression with n = 1.3, no clearance and volumetric efficiency of 100% calculate (i) pressure ratio, (ii) Indicated power, (iii) shaft power with mech. efficiency 80%, (iv) mass flow rateAnswer:

|

| Q 5 b ) |

8 |

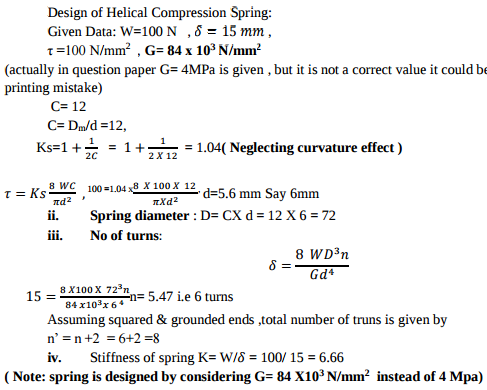

Question:Design a helical compression spring with ground ends. The spring index is 12. Maximum load on the spring is 100N and deflection under maximum load is 15 mm. Allowable shear stress of the material is 100 MPa and modulus of rigidity is 4 MPa. Find wire and spring diameters, number of coils and stiffness of spring.Answer:

|

| Q 5 b ) |

8 |

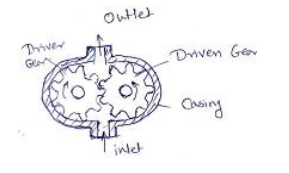

Question:Explain construction and working of gear pump.Answer: It consists of a pump housing in which a pair of precisely machined meshing gears runs with minimal radial and axial clearance as shown in fig. One of the gears, called a driver, is driven by a prime mover. The driver drives another gear called a follower. As the teeth of the two gears separate, the fluid from the pump inlet gets trapped between the rotating gear cavities and pump housing. The trapped fluid is then carried around the periphery of the pump casing and delivered to outlet port. The teeth of precisely meshed gears provide almost a perfect seal between the pump inlet and the pump outlet. When the driver is rotated by prime mover and driven will also rotate. Thus partial vacuum is created at the inlet of the pump. Fluid is forced to enter into the pump at atmospheric pressure. Fluid is trapped in the pockets between teeth and the casing and carried towards the outlet port.

|

| Q 5 c ) |

8 |

Question: Answer:

|

| Q 5 c ) |

8 |

Question:Explain with neat sketch construction and working of constant volume gas turbine.Answer: Constant volume gas turbine Working:- Air from surrounding atmosphere is drawn in compressor and is compressed to a pressure of about 3 kN/m2 . The compressed air is then admitted to the combustion chamber through the inlet valve. When inlet valve is closed, the fuel oil is admitted by means of a separate fuel pump into combustion chamber containing compressed air. The mixture (of air and fuel oil) is then ignited by an electric spark, the pressure rising to about 12 kN/m2 , whilst the volume remains constant. Thus combustion takes place at constant volume.

|

| Q 5 c ) |

8 |

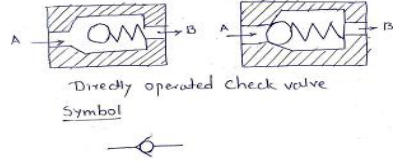

Question:Explain working of directly operated (Poppet type) check valve with neat sketch.Answer: When oil under pressure is supplied to port A, the oil exerts pressure on the ball against the spring force, hence the ball will be lifted off from its seat and creates a passage for

oil to flow. Hence oil can flow from port A to port B. when under pressure is supplied in opposite direction that is to port B, the oil force the ball to sit firmly in its seat, hence the passage is closed by ball. The oil cannot flow port B to port A. ----------------------------------------------------------------------------------------------------- |

| Q 5c)(i) |

8 |

Question:State the steps involved in selection of a proper ball bearing from a manufacturer’s catalogue.Answer: Steps Involved in selection of a proper ball bearing from Manufacture’s Cataloge

|

| Q 5c)(ii) |

8 |

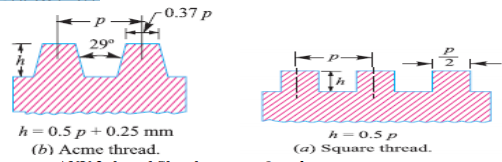

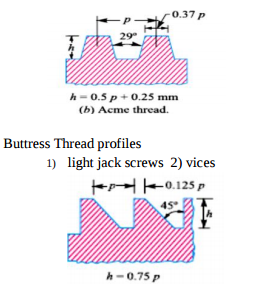

Question:State two engineering applications of each of Acme and Buttress thread profiles with neat sketches.Answer: Engg. Application of ACME Thread profiles : 1)screw cutting lathes,2) brass valves,3) cocks and 4) bench vices.

|

| Q 6 a ) |

4 |

Question:What is the necessity of purification of air in compressor and how it is done ?Answer: Necessity of purification of air in compressor : Air contains dust and dirt particles which are dangerous to the compressor valves and operation . so purification of air is necessary. It is the process of separating emulsified, suspended and separate oil as well as other contaminations from water phase of compressed air. Air cleaners are used for purification process of air . it reduces noise level also. Following are different types of air cleaners 1. Oil bath type air cleaner 2. Dry type air cleaner 3. Oil wetted type air cleaner 4. Paper pleated type air cleaner 5. Centrifugal type air cleaner ----------------------------------------------------------------------------------------------------- |

| Q 6 a ) |

4 |

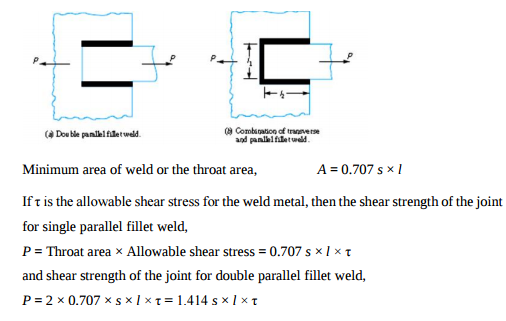

Question:Derive strength equation for parallel fillet weld subjected to tensile load.Answer: Derivation of strength equation for parallel fillet weld subjected to tensile load The parallel fillet welded joints are designed for shear strength. Consider a double parallel fillet welded joint as shown in Fig.

|

| Q 6 a ) |

4 |

Question:In cold climate why oil tank is equipped with oil heaters? Explain.Answer: Oil heaters: When hydraulic circuit works in cold climate, then oil is solidifies below 5 o C temperature. To liquefy the oil electrical heater or thermostatic heater are equipped with oil tank. This increase the operating and maintenance cost of hydraulic system The cost of hydraulic system is higher. It heats the oil so that its viscosity increases and it can flow in the system smoothly. Thermostatically controlled oil heater commonly used ----------------------------------------------------------------------------------------------------- |

| Q 6a)(i) |

4 |

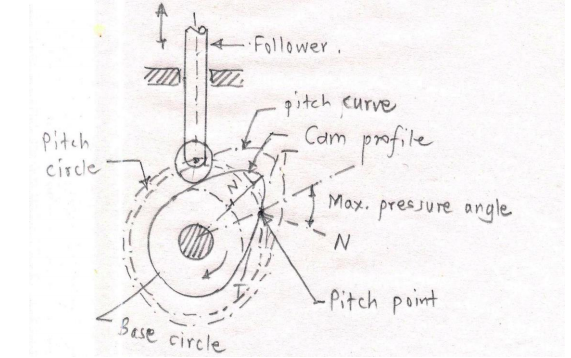

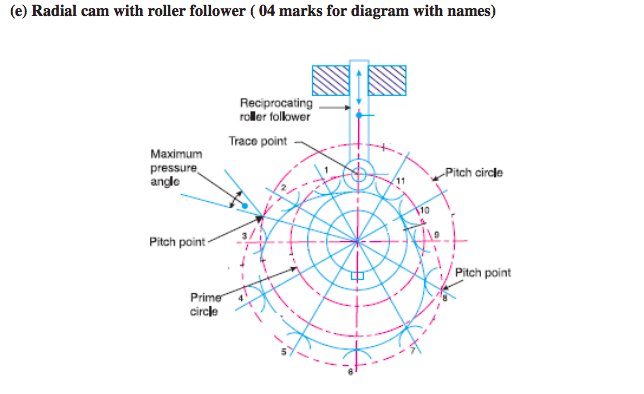

Question:Define the following terms as applied to cam with neat sketch. (1) Pitch circle (2) Pressure angle (3) Stroke of follower (4) ModuleAnswer: (1) Pitch circle- Circle drawn from centre of cam through pitch points. (2) Pressure angle- Angle between direction of follower motion and normal to pitch curve. (3) Stroke- Maximum travel of follower from its lowest position to top most position. (4) Module –(Gears) – Ratio of pitch circle diameter in mm to No. of teeth on gear.

|

| Q 6a)(ii) |

4 |

Question:Differentiate between disc brake and internally expanding brake.Answer:

|

| Q 6 b ) |

4 |

Question:A diesel engine has a compression ratio of 14 and cut-off takes place at 6% of stroke. Find the air standard efficiency.Answer:

|

| Q 6 b ) |

8 |

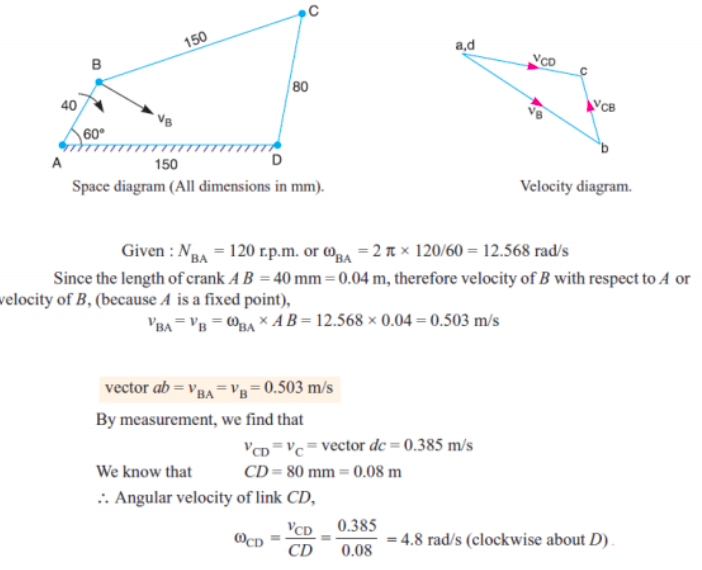

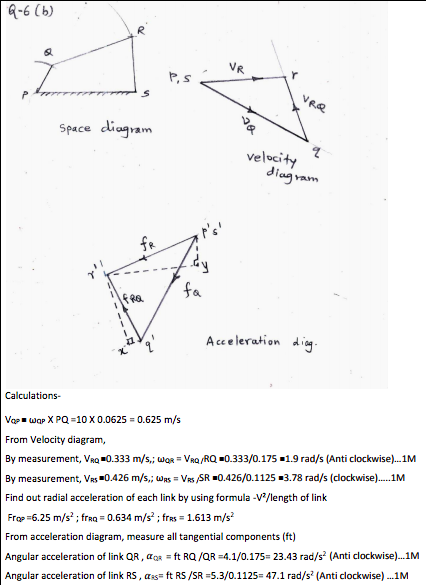

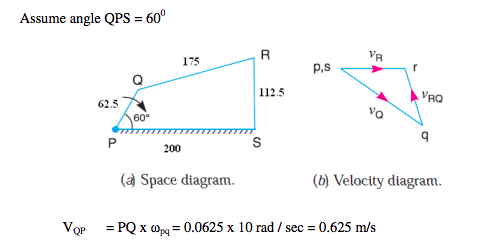

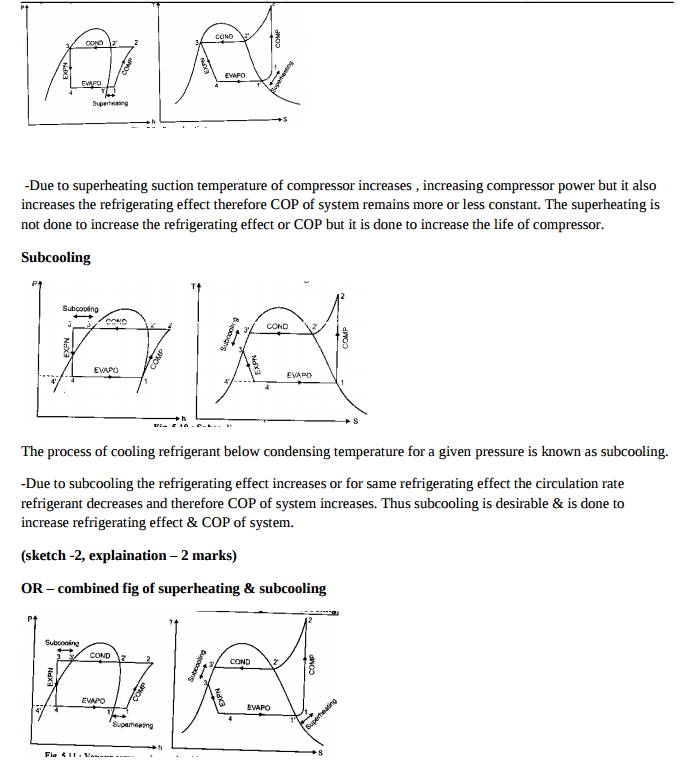

Question:PQRS is a four bar chain with link PS fixed. The lengths of links are PQ = 62.5mm, QR = 175mm, RS = 112.5mm and PS = 200mm, The crank PQ rotates at 10 rad/sec clockwise. Draw velocity and acceleration diagram, when angle QPS = 60° and Q and R lie on the same side of PS. Find the angular velocity and angular acceleration of links QR and RS.Answer:

|

| Q 6 b ) |

4 |

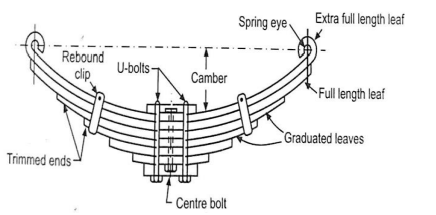

Question:State two applications of leaf spring. Draw neat sketch of leaf springAnswer: Application of Leaf spring Bus/truck/Car suspension springs, diving board, Sketch of Leaf Spring of semi elliptical Type

Given Data: D=250 mm , P=1.5 N/mm2 , n =12 Nos. ,σt = 30 Mpa ----------------------------------------------------------------------------------------------------- |

| Q 6 b ) |

4 |

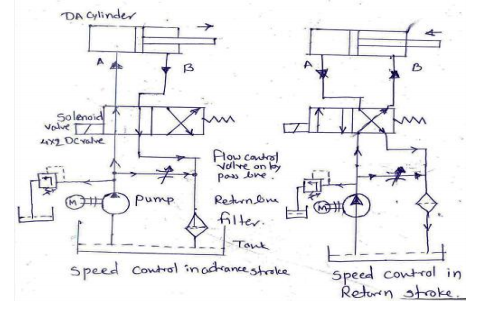

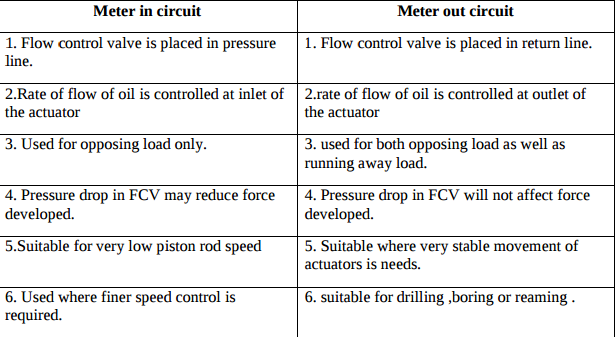

Question:Compare meter in circuit and meter out circuitAnswer:

|

| Q 6 c ) |

4 |

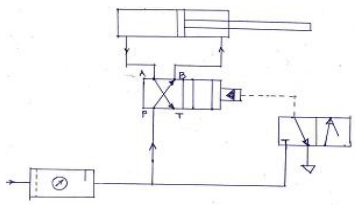

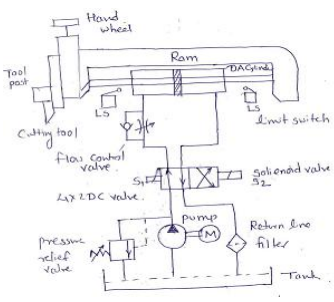

Question:Draw the hydraulic circuit for shaping machine. Explain its workingAnswer:

Parts of shaper machine: Fixed DA cylinder, spool type DC valve, spool shaft stroke adjusting lever, pump, pressure relief valve, return line with filter, oil reservoir. Working: Forward stroke: As shown in fig ,the pump is supplying oil to DA cylinder through DC valve and through port B. Hence piston will move from right to left with force and this is a cutting stroke. Backward Stroke: When lever touches the stopper, then spool shifts to right and flow directions in DC valve change. The oil is entering through port A of DA cylinder and piston will move from left to right. During this stroke, the tool post slightly lift with ideal stroke. ----------------------------------------------------------------------------------------------------- |

| Q 6 c ) |

4 |

Question:Define (i) Dew point temp. (ii) Wet bulb tempAnswer: i) DPT – Dew point temperature tDP - It is the temperature at which air water vapour mixture starts to condense. D.P.T. of mixture is defined as the temperature at which water vapours starts to condense. Ii) WBT - Wet bulb temperature - tWB - It is the temperature recorded by thermometer when its bulb is covered with wet cloth known as wick and is exposed to air. ----------------------------------------------------------------------------------------------------- |

| Q 6 c ) |

8 |

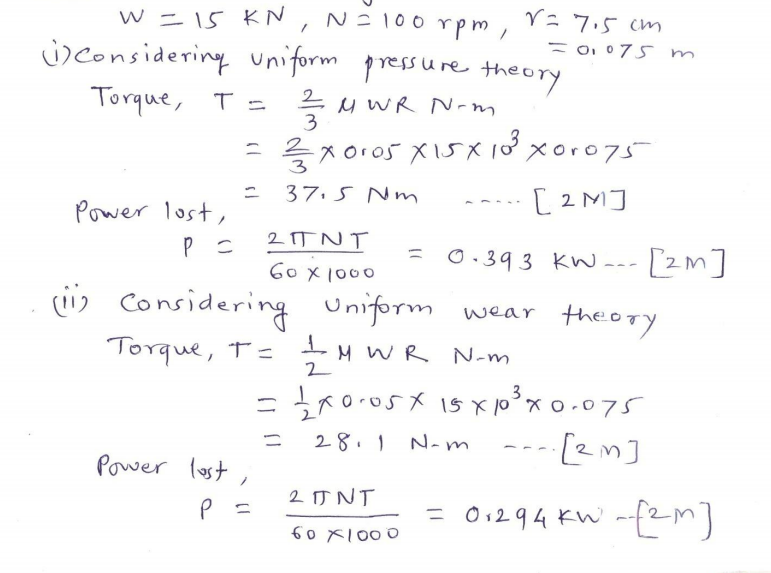

Question:Determine the power lost in a footstep bearing due to friction if a load of 15 kN is supported and the shaft is rotating at 100 r.p.m. The diameter of bearing is 15cm and coefficient of friction is 0.05. Assume : (i) Uniform wear condition (ii) Uniform pressure condition.Answer:

|

| Q 6 c ) |

4 |

Question:A steam engine cylinder has effective diameter of 250 mm. It is subjected to maximum steam pressure of 1.5 MPa. The cylinder cover is fixed to the cylinder with the help of 12 bolts. The pitch circle diameter of bolts is 400 mm. Permissible tensile stress of the bolt material is 30 MPa. Determine nominal diameter of the bolts.Answer:

----------------------------------------------------------------------------------------------------- |

| Q 6 d ) |

4 |

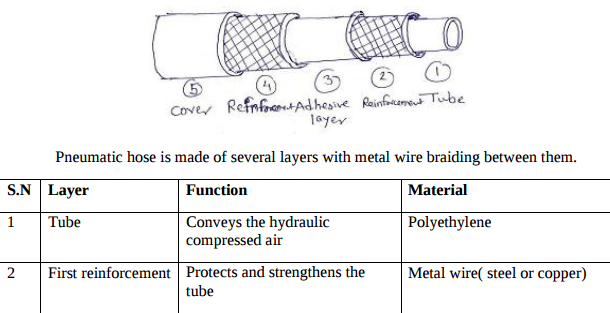

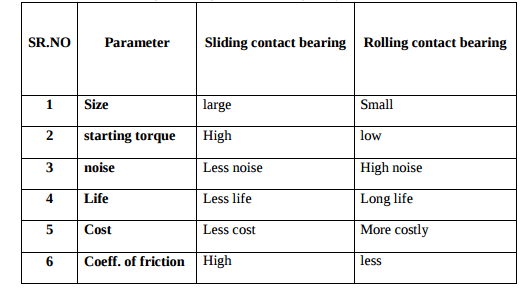

Question:Draw constructional details of pneumatic hose. Why hose is required in pneumatic circuits?Answer:

|

| Q 6 d ) |

4 |

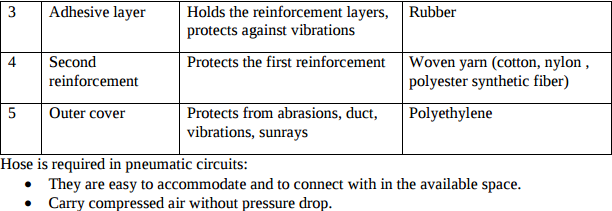

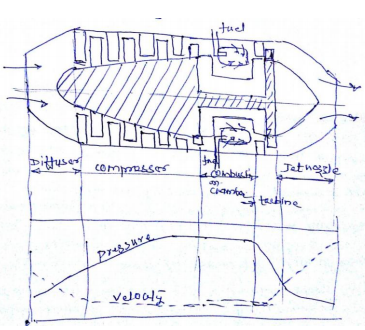

Question:Explain the principle of Ram jet with neat sketchAnswer: Ram jet – (Fig – 2 marks ; explanation –2 marks) - Ram jet is also called as ‘Athodyd or flying stove pipe’. - It is a steady combustion or continuous flow engine & has the simplest construction of any propulsion engine. - Consist of inlet diffuser, combustion chamber & exit nozzle. - Air entering into ram jet with supersonic speed is slowed down to sonic speed in supersonic diffuser, increasing air pressure. - The air pressure is further increased in the subsonic diffuser. - The fuel injected into the combustion chamber is burned with the help of flame stabilizers. The high temp & high pressure gases are passed through the nozzle converting the pressure energy into kinetic energy. - It is not self operating at zero flight velocity. It requires launching rockets.

|

| Q 6 d ) |

4 |

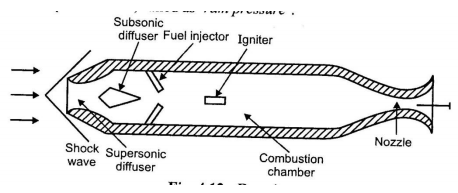

Question:Differentiate between sliding contact and rolling contact type bearings.Answer:

----------------------------------------------------------------------------------------------------- |

| Q 6 e ) |

4 |

Question:How can the speed control of any actuator be achieved? Explain the speed control circuit of bi directional air motor with sketch.Answer: Speed control of any actuator (Cylinders or motors) can be controlled using flow control valves. Varying the rate of flow of oil will vary the speed of the actuator.(Explanation 1Mark) In meter in circuit, rate of flow of oil is controlled at inlet of the actuator. In meter out circuit, rate of flow of oil is controlled at outlet of the actuator. In bleed off circuit, rate of flow of oil is controlled in the by-pass line leading towards the tank. Speed control of bi-directional air motor: (Sketch 1Marks and Explanation 2 Marks) Bi-directional air motor rotates in clockwise as well as anti-clockwise direction. The speed of bi-directional motor is controlled as shown in fig. The speed control of motor by using variable two flow control valves having built-in check valve and 4x3 DC valve having zero position or central hold position with lever L1 and L2. When lever L1 is operated, port P will be connected to port A of air motor and motor will start rotating in clockwise direction. Its speed can be controlled by using variable flow control valve F1. Port B of motor will be connected to exhaust R and air in motor will be exhausted through port R via DC valve. When lever L2 is operated, pressure port P will be connected to port B of motor and naturally motor will start rotating in anticlockwise direction. Port A will be connected to port R and air in the motor will be exhausted through port R via DC valve.

|

| Q 6 e ) |

4 |

Question:State one application each of (i) Deep groove ball bearing (ii) Taper roller bearing (iii) Thrust roller bearing (iv) Needle roller bearingAnswer: Application of bearings : …… i) Deep Groove Ball bearing : Electric Motor ii) Taper roller bearing : axle housing of automobile iii) Thrust collar bearing: Clutch of automobile iv) Needle roller bearing: Differential of automobile ----------------------------------------------------------------------------------------------------- |

| Q 6 e ) |

4 |

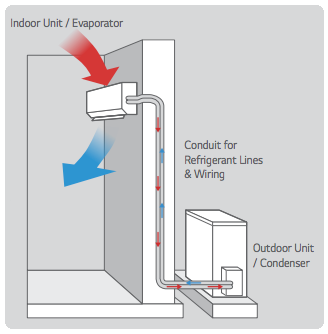

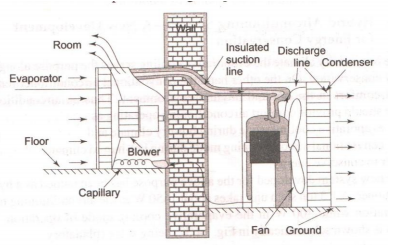

Question:Draw neat sketch of split air conditioner and name the parts.Answer: Split Air-conditioner labeled Diagram 02 for figure 02 for labeling

|

| Q 6 e ) |

4 |

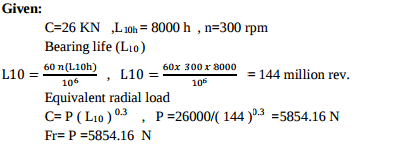

Question:A taper roller bearing has a dynamic load capacity of 26 kN. The desired life for 90% of the bearing is 8000 hr. and speed is 300 rpm. Calculate equivalent radial load that the bearing can carryAnswer:

|

| Que.No | Marks | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Q 1a)(a) |

4 |

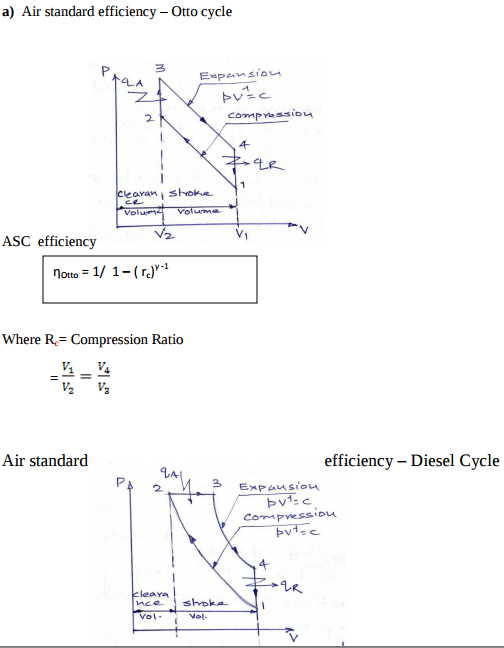

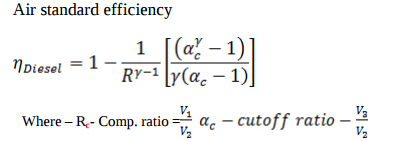

Question:Write the equations for air standard efficiency of otto cycle and diesel cycle and state various terms involved in it.Answer:

|

||||||||||||

| Q 1a)(a) |

2 |

Question:Define kinematic link and kinematic chain.Answer: Each part of a machine, which moves relative to some other part, is known as a kinematic link. When the kinematic pairs are coupled in such a way that the last link is joined to the first link to transmit definite motion (i.e. completely or successfully constrained motion), it is called a kinematic chain. ----------------------------------------------------------------------------------------------------- |

||||||||||||

| Q 1a)(b) |

4 |

Question:Define : i) Compression ratio (Rc) ii) Swept volume (vs) iii) Cut off ratio iv) Clearance volume (vc)Answer:

|

||||||||||||

| Q 1a)(b) |

2 |

Question:Enlist the different type of follower motion.Answer: Motion of the Follower : 1. Uniform velocity, 2. Simple harmonic motion, 3. Uniform acceleration and retardation, and 4. Cycloidal motion. ----------------------------------------------------------------------------------------------------- |

||||||||||||

| Q 1a)(c) |

4 |

Question:Write uses of compressed air.Answer: Uses of compressed air:- 1. Cleaning automobiles 2. Pneumatic tools 3. Supercharging in I.C. engines 4. Cooling of large building 5. Construction of bridges, roads etc. 6. Spraying points 7. Spraying fuel in high speed diesel engine 8. Starting of I.C. engines ----------------------------------------------------------------------------------------------------- |

||||||||||||

| Q 1a)(c) |

2 |

Question:Define angle of lap and slip in belt drive.Answer: Slip of belt : The motion of belts and shafts assuming a firm frictional grip between the belts and the shafts. But sometimes, the frictional grip becomes insufficient. This may cause some forward motion of the driver without carrying the belt with it. This may also cause some forward motion of the belt without carrying the driven pulley with it. This is called slip of the belt and is generally expressed as a percentage. Angle of Lap : The angle of lap is defined as the angle subtended by the portion of the belt which is in contact at the pulley surface of the pulley. ----------------------------------------------------------------------------------------------------- |

||||||||||||

| Q 1a)(d) |

4 |

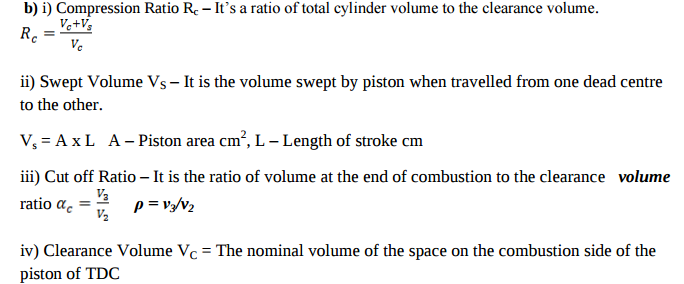

Question:Draw a neat sketch of vane compressor and label the different parts.Answer:

|

||||||||||||

| Q 1a)(d) |

2 |

Question:State four conditions under which the ‘V’ belt drive is selected.Answer: Conditions for ‘V’ Belt drive selection : 1. Great amount of Power to be transmitted, 2. Requirement of the high velocity ratio (maximum 10). 3. Small Centre distance between the shafts 4. Positive drive requirement 5. Compact Space ----------------------------------------------------------------------------------------------------- |

||||||||||||

| Q 1a)(e) |

2 |

Question:State the function of Governor in an I.C. engine.Answer: The function of a governor is to regulate the mean speed of an engine, when there are variations in the load e.g. when the load on an engine increases, its speed decreases, therefore it becomes necessary to increase the supply of working fluid. On the other hand, when the load on the engine decreases, its speed increases and thus less working fluid is required. The governor automatically controls the supply of working fluid to the engine with the varying load conditions and keeps the mean speed within certain limits. ----------------------------------------------------------------------------------------------------- |

||||||||||||

| Q 1a)(f) |

2 |

Question:State four applications of flywheel.Answer: Applications of flywheel : Used in Internal combustion engines, press machines, mills, punching machines. ----------------------------------------------------------------------------------------------------- |

||||||||||||

| Q 1a)(g) |

2 |

Question:Give the classification of dynamometer. State the function of it.Answer: Function of dynamometer: A dynamometer is a brake but in addition it has a device to measure the frictional resistance. Knowing the frictional resistance, we may obtain the torque transmitted and hence the power of the engine. Absorption type dynamometers: 1. Prony brake dynamometer, and 2. Rope brake dynamometer. Transmission type dynamometers 1. Epicyclic-train dynamometer, 2. Belt transmission dynamometer, and 3. Torsion dynamometer. ----------------------------------------------------------------------------------------------------- |

||||||||||||

| Q 1a)(h) |

2 |

Question:Why is balancing of rotating parts necessary for high speed engines ?Answer: The high speed of engines and other machines is a common phenomenon now-a-days. It is, therefore, very essential that all the rotating and reciprocating parts should be completely balanced as far as possible. If these parts are not properly balanced, the dynamic forces are set up. These forces not only increase the loads on bearings and stresses in the various members, but also produce unpleasant and even dangerous vibrations. The balancing of unbalanced forces is caused by rotating masses, in order to minimize pressure on the main bearings when an engine is running. ----------------------------------------------------------------------------------------------------- |

||||||||||||

| Q 1b)(a) |

6 |

Question:What is the necessity of I.C. Engine Testing ? What are the different test carried out on I.C. Engines ?Answer: Necessity of I.C. engine testing i) To get information, that is not possible to be determine by calculations. ii) To confirm the validity of data used while designing the engine. iii) To satisfy the customer as to rated power with guarantied fuel consumption. iv) To reduce the cost and to improve the power output and reliability of an engine. v) To know & improve the performance of an engine. Test carried out on I.C. Engine – 1) Commercial Tests 2) Thermodynamic Tests 1) Commercial Tests – These tests are carried out in order to check following a) Rated power out-put with guarantied fuel consumption in kg/kw hr b) Quantity of lubricating oil per kw-hr c) Quantity of cooling water per kw-hr d) Steadiness of engine under varied load conditions e) Overload carrying capacity of the engine 2) Thermodynamic Tests – These tests are carried out for the purpose of comparing actual results with theoretical results by measuring following parameters and then drawing heat balance sheet. i) Indicated power ii) Brake power iii) Frictional power iv) Rate of fuel consumption v) Rate of flow of cooling water and its temperature rise vi) Heat carried by exhaust gas ----------------------------------------------------------------------------------------------------- |

||||||||||||

| Q 1b)(a) |

4 |

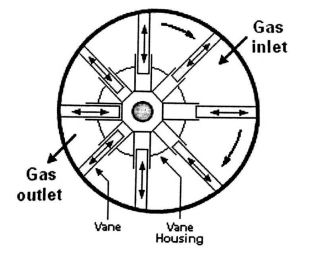

Question:Define completely constrained motion and successfully constrained motion with neat sketch. State one example of each.Answer:

|

||||||||||||

| Q 1b)(b) |

6 |

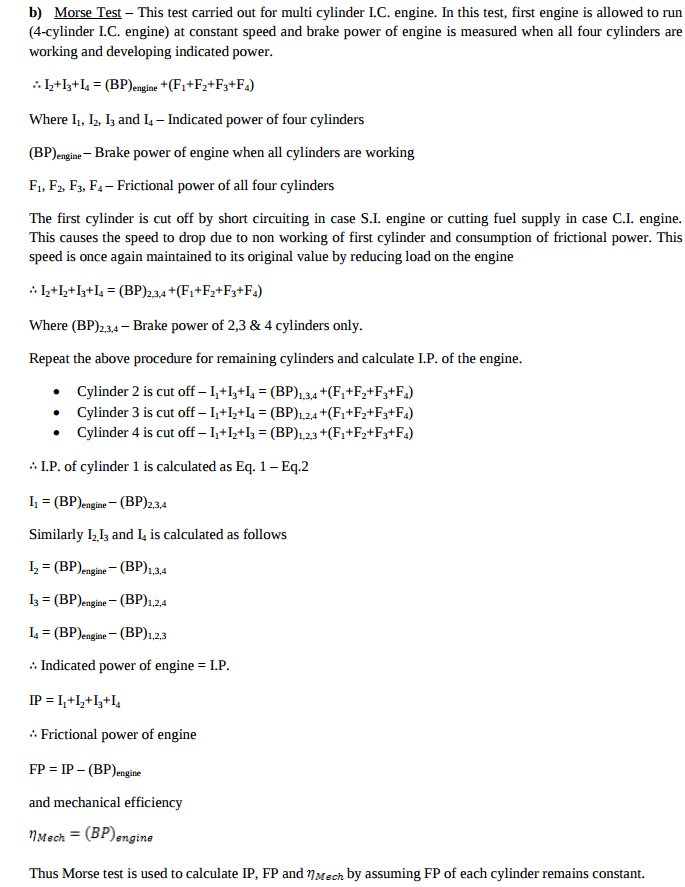

Question:Explain the procedure for conducting Morse test.Answer:

|

||||||||||||

| Q 1b)(b) |

4 |

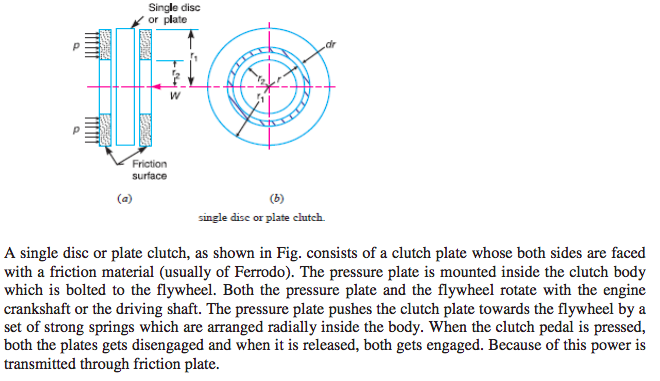

Question:Explain working principle of clutch. State its location in transmission system of an automobile.Answer: A friction clutch has its principal application in the transmission of power of shafts and machines, which must be started and stopped frequently. The force of friction is used to start the driven shaft from rest and gradually brings it up to the proper speed without excessive slipping of the friction surfaces. In automobiles, friction clutch is used to connect the engine to the driven shaft. In operating such a clutch, care should be taken so that the friction surfaces engage easily and gradually brings the driven shaft up to proper speed. Location: Between the engine and gear box.

----------------------------------------------------------------------------------------------------- |

||||||||||||

| Q 1b)(c) |

4 |

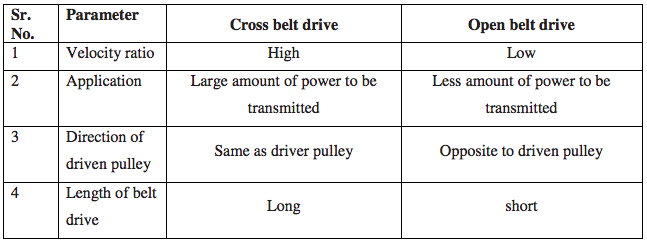

Question:Compare cross belt drive and open belt drive on the basis of (i) velocity ratio (ii) application (iii) direction of driven pulley (iv) length of belt driveAnswer: Comparison between cross belt drive and open belt drive :

|

||||||||||||

| Q 2 a ) |

4 |

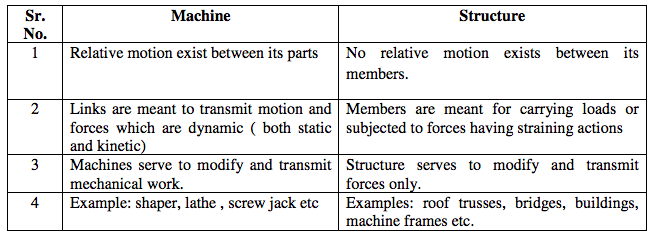

Question:Differentiate machine and structure on any four points.Answer:

|

||||||||||||

| Q 2 a ) |

8 |

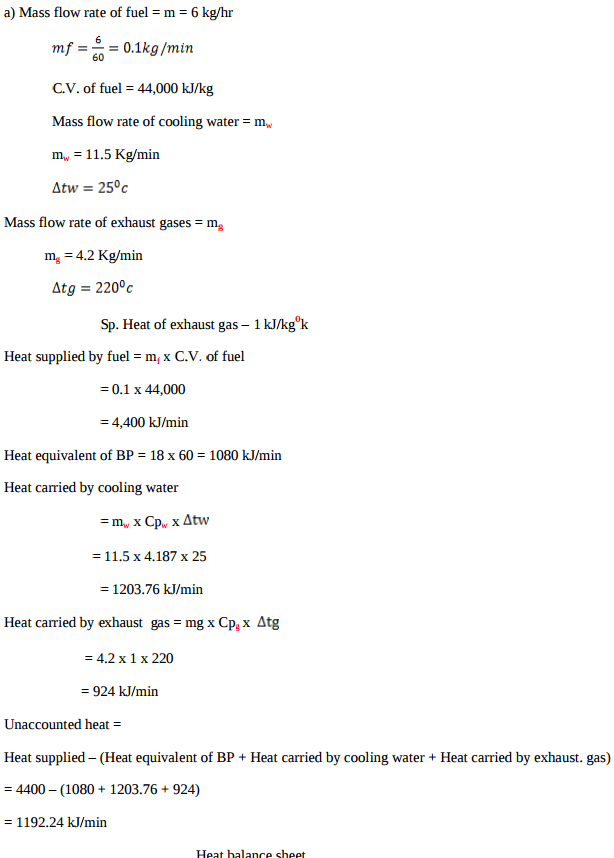

Question:An I.C. Engine uses 6 kg of fuel having calorific value 44000 kJ/kg in one hour. The IP developed is 18 kW. The temperature of 11.5 kg of cooling water was found to rise through 25°C per minute. The temperature of 42 kg of exhaust gas with specific heat 1 kJ/kg°k was found to rise through 220°C. Draw the heat balance sheet for the engine.Answer:

|

||||||||||||

| Q 2 b ) |

4 |

Question:Explain with neat sketch working principle of Oldham’s coupling.Answer:

When the driving shaft A is rotated, the flange C (link 1) causes the intermediate piece (link 4) to rotate at the same angle through which the flange has rotated, and it further rotates the flange D (link 3) at the same angle and thus the shaft B rotates. Hence links 1, 3 and 4 have the same angular velocity at every instant. A little consideration will show that there is a sliding motion between the link 4 and each of the other links 1 and 3. ----------------------------------------------------------------------------------------------------- |

||||||||||||

| Q 2 b ) |

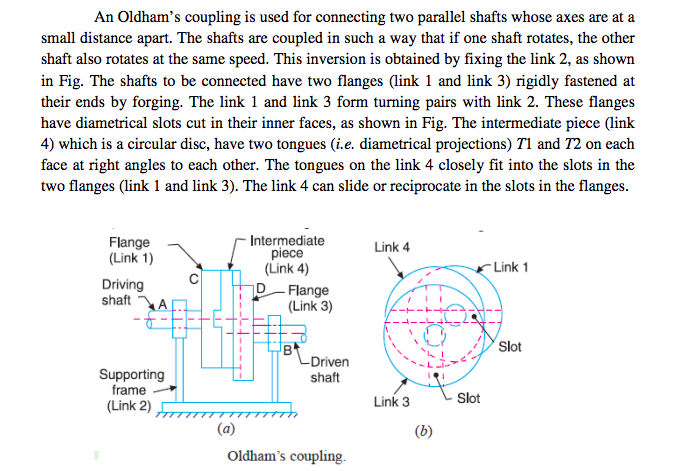

8 |

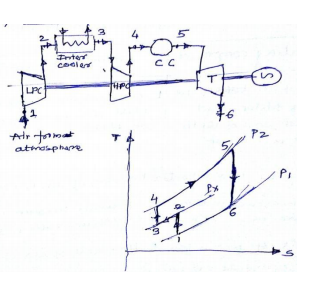

Question:What is the necessity of multistage compression ? Explain the working of two stage reciprocating air compressor with intercooler, with the help of p-v diagram.Answer: Necessity of multistage compression i) As index of compression ‘n’ increases it increases compression work. ii) Increase in pressure ratio (P2/P1) it increases work as well as size of cylinder. iii) Increment in pressure ratio (P2/P1) beyond certain limit, volumetric efficiency decreases while it increases leakage loss on either sides the piston and valves. Due to above pointes and for higher pressure ratio compressor needs multistaging.

Fig. shows arrangement of two stage reciprocating air compressor with inter cooler and its working shown on P.V. diagram plane. Processes occurred in the cycle - 1 – 2 – suction process by LP cylinder to draw atmospheric pressure - 2 – 3 – compression process by LP cylinder up to pressure P2 - 3 – 4 – delivery of compressed air into the air cooler - 4 – 5 – during this process air rejects the heat to the cold water and at the same time suction process by HP cylinder to draw air from air cooler. - 5 – 6 – compression pressure by HP cylinder up to required pressure P3 - 6 – 7 – delivery of compressed air at required pressure to the point of use. This completes the process and system has shown saving in work shown by shaded portion. ----------------------------------------------------------------------------------------------------- |

||||||||||||

| Q 2 c ) |

4 |

Question:Define linear velocity, angular velocity, absolute velocity and state the relation between linear velocity and angular velocity.Answer:

|

||||||||||||

| Q 2 c ) |

8 |

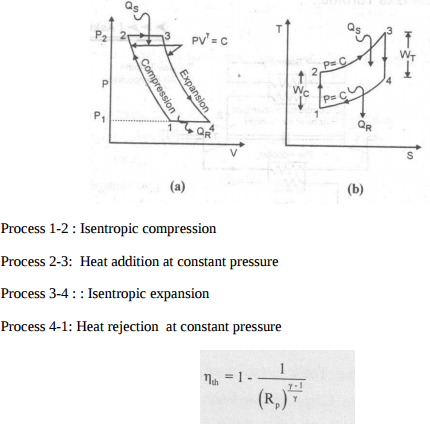

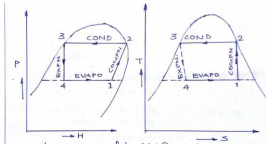

Question:Explain vapour compression refrigeration (for dry saturated state of refrigerant) cycle with the help of P-h and T-s charts.Answer:

Processes in VCR cycle 1) The point 1 represents condition of refrigerant at entry of compressor which is wet. Process 1 – 2 – Isentropic compression of refrigerant vapour till it becomes dry and saturated. Process 2 – 3 – Condensation of vapour refrigerant up to saturated liquid condition at constant pressure. Process 3 – 4 – Expansion of liquid refrigerant by expansion device. This reduces pressure as well as temperature of liquid refrigerant. Process 4 – 1 – Evaporation of liquid refrigerant in the evaporator thus establishing required refrigerating effect. Thus it completes one cycle of refrigeration. Refrigerating effect = RE = m (h1 – h4) Compressor power = m (h2 – h1) Where m = mass flow rate of refrigerant in kg/sec.

|

||||||||||||

| Q 2 d ) |

4 |

Question:Describe stepwise procedure for determination of velocity and acceleration by Klein’s construction with suitable data.Answer: Steps in Klein’s construction : Klein’s construction is a simpler construction to get velocity and acceleration diagrams. For example : for reciprocating engine mechanism OPC. draw a circle with PC as diameter as shown. and obtain velocity diagram OCM ie. produce PC to cut perpendicular to line of stroke in ‘M’ . Draw another circle with ‘C’ as center and “CM” as radius cutting the first circle in points K and L. Join “KL” which is the chord common to both the circles. Let it cuts PC and OP in “Q” and “N” respectively. Then “OCQN” is the required quadrilateral which is similar to acceleration diagram.

|

||||||||||||

| Q 2 e ) |

4 |

Question:Draw a neat sketch of radial cam with roller follower and show the following on it : (i) Pitch point (ii) Pressure angle (iii) Prime circle (iv) Trace pointAnswer:

|

||||||||||||

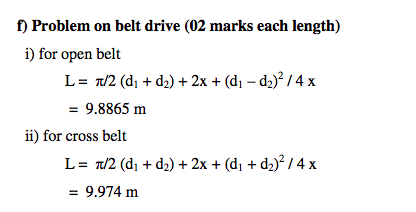

| Q 2 f ) |

4 |

Question:The central distance between two shaft is 4 m having two pulleys with diameter having 500 mm and 700 mm respectively. Find length of belt required (i) for open belt drive (ii) for cross belt driveAnswer:

|

||||||||||||

| Q 3 a ) |

4 |

Question:Draw a neat labelled sketch of “Multiplate Clutch”.Answer:

|

||||||||||||

| Q 3 a ) |

4 |

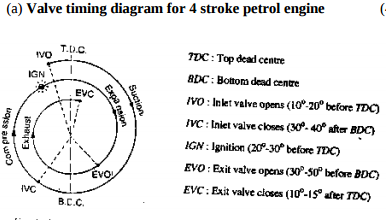

Question:Draw actual valve timing diagram for 4-stroke petrol engine.Answer:

|

||||||||||||

| Q 3 b ) |

4 |

Question:Why roller follower is preferred over a knife follower ? State two advantages and application of roller follower.Answer: In case of knife edge follower there is sliding motion between the contacting surface of cam and follower. Because of small contact area, there is excessive wear; therefore it is not frequently used. Whereas in roller follower there is rolling motion between contacting surfacing and more contact area, therefore rate of wear is greatly reduced. Advantages: i) Less wear, more life ii) Less side thrust as compared to knife edge follower. Application: Used in stationary oil and gas engines ----------------------------------------------------------------------------------------------------- |

||||||||||||

| Q 3 b ) |

4 |

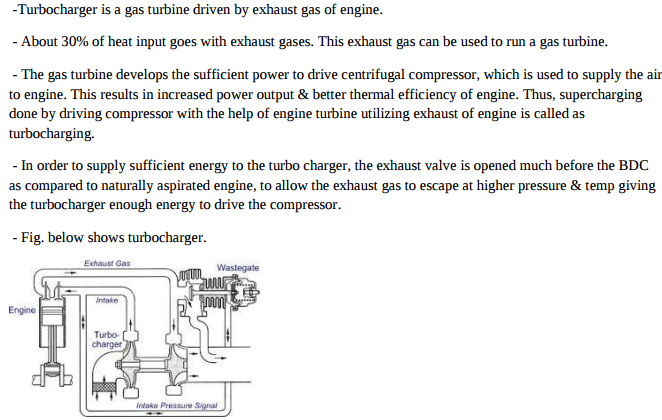

Question:Explain turb charging with a neat sketch.Answer:

|

||||||||||||

| Q 3 c ) |

4 |

Question:Write the procedure for balancing of a single rotating mass by single masses rotating in the same plane.Answer:

|

||||||||||||

| Q 3 c ) |

4 |

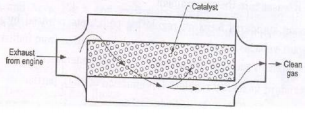

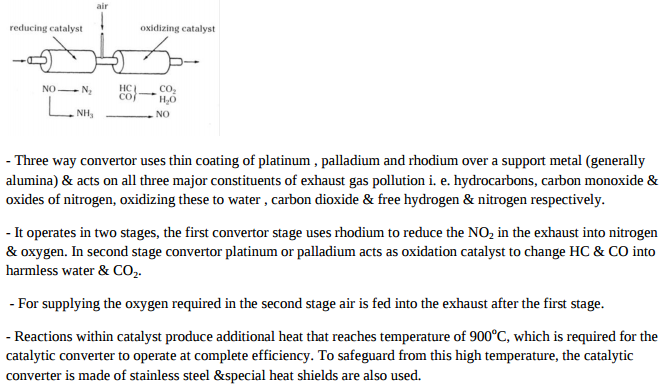

Question:Explain three way catalytic convertor.Answer:

|

||||||||||||

| Q 3 d ) |

4 |

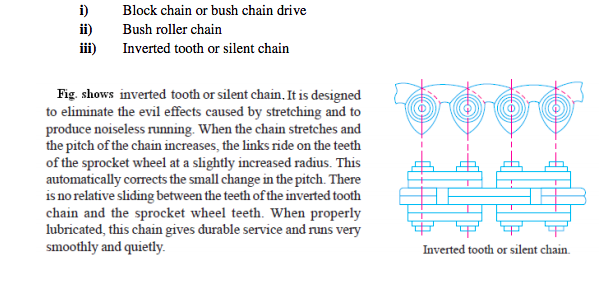

Question:State the type of power transmission chains. Describe any one with its sketch.Answer: Types of power transmission chains :

|

||||||||||||

| Q 3 d ) |

4 |

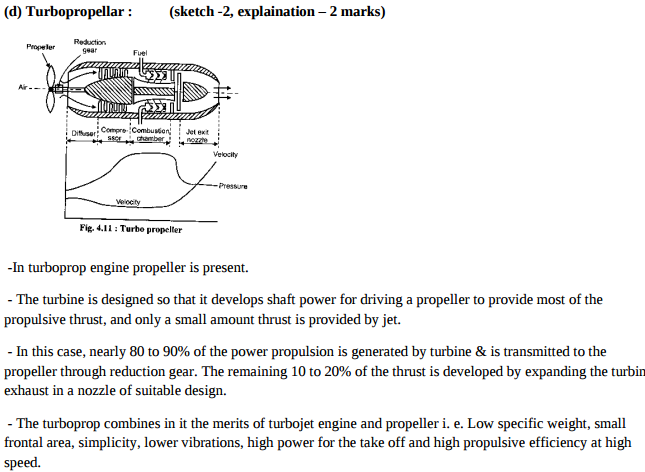

Question:Explain with a neat sketch turbo propeller w.r.to Jet propulsionAnswer:

|

||||||||||||

| Q 3 e ) |

4 |

Question:PQRS is a four bar chain with PS fixed length of links are PQ = 62.5 mm, QR =175 mm, RS = 112.5 mm, PS = 200 mm. The crank PQ rotate at 10 rad/sec. in clockwise direction. Determine the angular velocity of point R, graphically by using relative velocity method.Answer:

|

||||||||||||

| Q 3 e ) |

4 |

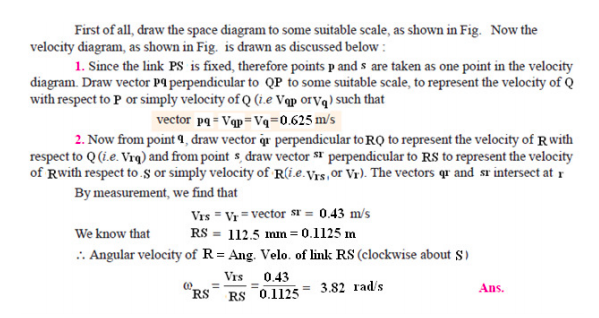

Question:Explain the concept of super heating and sub cooling with the help of P-h and T-s chartsAnswer:

|

||||||||||||

| Q 3 f ) |

4 |

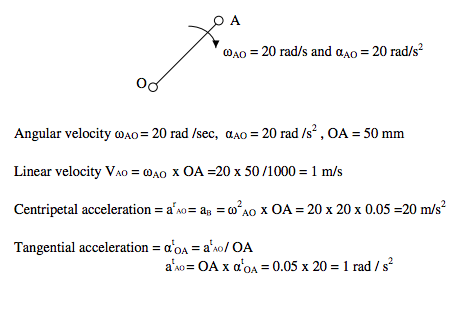

Question:Crank OA of a mechanism is hinged at ‘O’ and rotates at an angular velocity of 20 rad/sec. and angular acceleration of 25 rad/sec2 . If crank OA is 50 mm long determine linear velocity, centripetal acceleration and tangential acceleration of a point A.Answer:

|

||||||||||||

| Q 4 a ) |

4 |

Question:What are the causes of detonation in I.C. engine ?Answer: The loud pulsating noise heard within the engine cylinder is known as detonation. The following are the certain factors which causes detonation. (1) The shape of the combustion chamber. (2) The relative position of the sparking plugs in case of petrol engines. (3) The chemical nature of the fuel. (4) The initial temp & pressure of fuel (5) The rate of combustion of that portion of fuel which is the first to ignite. This portion of fuel in heating up , compresses the remaining unburnt fuel, thus producing the condition for auto ignition to occur. ----------------------------------------------------------------------------------------------------- |

||||||||||||

| Q 4 a ) |

4 |

Question:Explain the phenomenon of slip and creep in a belt drive. State its effect on velocity ratio.Answer: Slip of the belt: A firm frictional grip between belt and shaft is essential. But sometimes it becomes insufficient. This may cause some forward motion of the belt without carrying the driven pulley with it. This called as slip of the belt. It is expressed as a percentage. Effect on velocity ratio: Result of belt slipping is to reduce the velocity ratio of the system. Creep in belt drive : When the belt passes from slack side to tight side, a certain portion of the belt extends and it contracts again when the belt passes from tight sight to slack side. Due to these changes in length, there is a relative motion between the belt and the pulley surfaces. This relative motion is called as creep. Effect on velocity ratio: The total effect of creep is to reduce slightly the speed of the driven pulley or follower. ----------------------------------------------------------------------------------------------------- |

||||||||||||

| Q 4 b ) |

4 |

Question:What are the effects of pollutants on environment ?Answer: The major air pollutants emitted by petrol & diesel engines are CO2, CO, HC, NOx, SO2, smoke & lead vapour. Effect of CO: (1) Carbon monoxide combines with hemoglobin forming carboy hemoglobin ,which reduces oxygen carrying capacity of blood. (2) This leads to laziness, exhaustion of body & headache. (3) Prolong exposure can even leads to death. (4) It also affects cardiovascular system, thereby causing heart problem Effect of CO2: Causes respiratory disorder & suffocation. Effect of NOx: • It causes respiration irritation, headache, bronchitis, pulmonary emphysema, impairment of lung, loss of appetite , & corrosion of teeth to human body. Effect of HC: • It has effect like reduced visibility, eye irritation , peculiar odour & damage to vegetation & acceleration the cracking of rubber products. • It induce cancer, affect DNA & cell growth are know a carcinogens. Effect of SO2: It is toxic & corrosive gas, human respiratory track of animals, plants & crops ----------------------------------------------------------------------------------------------------- |

||||||||||||

| Q 4 b ) |

4 |

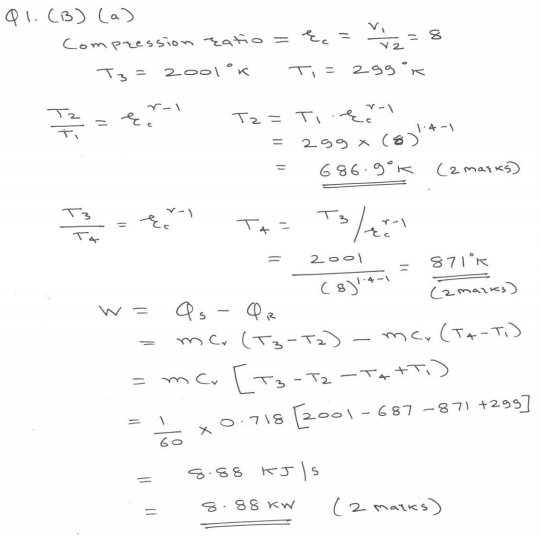

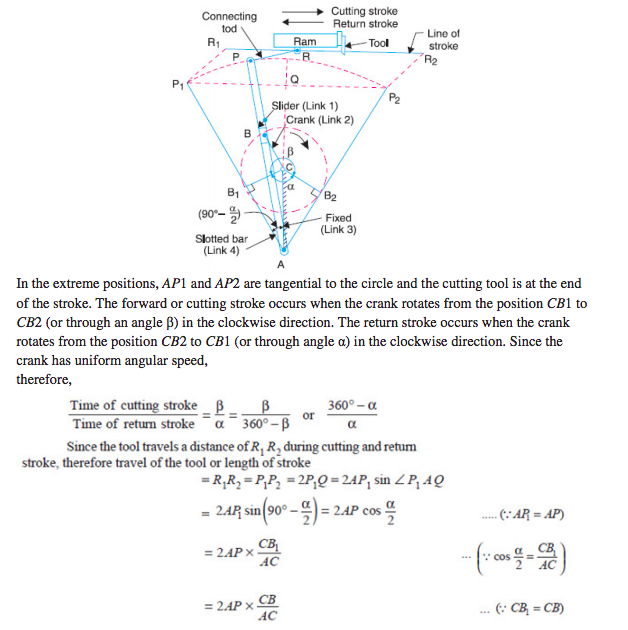

Question:Explain with the diagram working of crank and slotted lever quick return mechanism.Answer: Crank and slotted lever quick return motion mechanism: This mechanism is mostly used in shaping machines, slotting machines and in rotary internal combustion engines. In this mechanism, the link AC (i.e. link 3) forming the turning pair is fixed, as shown in fig. The link 3 corresponds to the connecting rod of a reciprocating steam engine. The driving crank CB revolves with uniform angular speed about the fixed centre C. A sliding block attached to the crank pin at B slides along the slotted bar AP and thus causes AP to oscillate about the pivoted point A. A short link PR transmits the motion from AP to the ram which carries the tool and reciprocates along the line of stroke R1R2. The line of stroke of the ram (i.e. R1R2) is perpendicular to AC produced.

----------------------------------------------------------------------------------------------------- |

||||||||||||

| Q 4b)(a) |

6 |

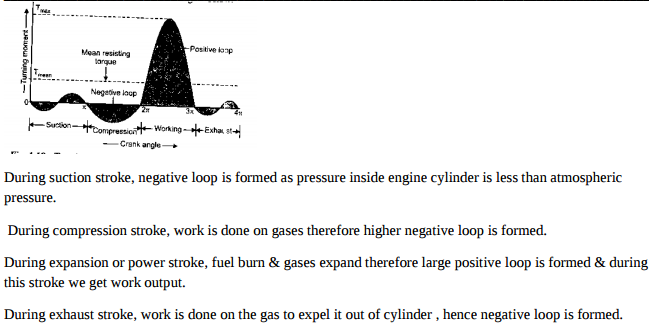

Question:Explain with neat sketch turning moment diagram for a four-stroke engine.Answer:

|

||||||||||||

| Q 4b)(b) |

6 |

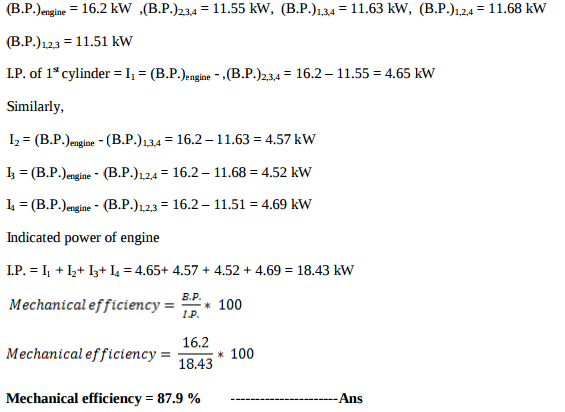

Question:The following results were obtained during Morse test on 4-stroke petrol engine. B.P. developed when all cylinders are working = 16.2 kW. B.P. developed when cylinder No. 1 cutt off = 11.55 kW. B.P. developed when cylinder No. 2 cut off = 11.63 kW B.P. developed when cylinder No. 3 cut off = 11.68 kW B.P. developed when cylinder No. 4 cut off = 11.51 kW Calculate mechanical efficiency of engine.Answer:

|

||||||||||||

| Q 4 c ) |

4 |

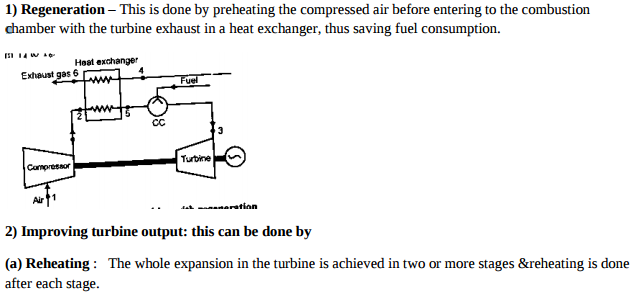

Question:What are the methods to improve thermal efficiency of gas turbine ? Explain any one method.Answer:

|

||||||||||||

| Q 4 c ) |

4 |

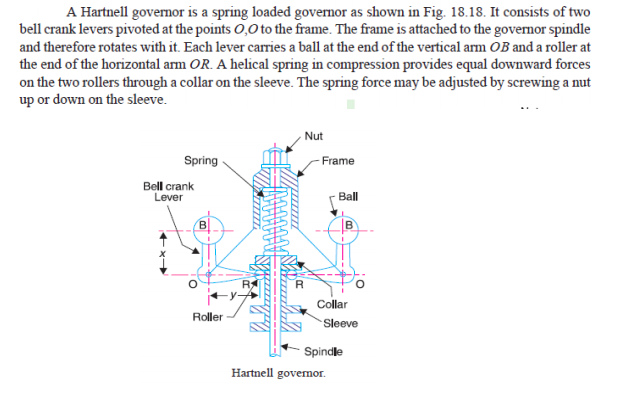

Question:Explain with sketch working of hartnell governor.Answer:

|

||||||||||||

| Q 4 d ) |

4 |

Question:What is jet propulsion ? Give the classification of jet propulsion system.Answer: Jet Propulsion: This is done by expanding the gas which is at high temperature & pressure through the nozzle so that the gas with very high velocity leaves the nozzle giving thrust in opposite direction. - Principle is based on Newton’s Second & third law of motion. Jet propulsion – Classification (1) Atmospheric jet engines (breathing engine) -Turbojet engine - Turbo prop engines - Ram jet (2) Rocket engine (Non - breathing engine) ----------------------------------------------------------------------------------------------------- |

||||||||||||

| Q 4 d ) |

4 |

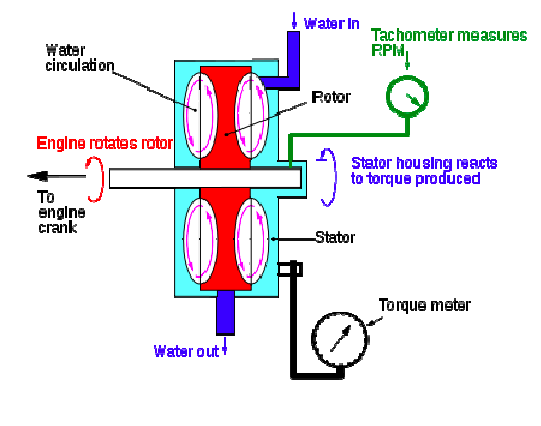

Question:Explain working of hydraulic brake dynamometer with sketch.Answer:

Hydraulic dynamometer is also called as water brake absorber. Invented by British engineer William Froude in 1877 in response to a request by the Admiralty to produce a machine capable of absorbing and measuring the power of large naval engines, water brake absorbers are relatively common today. The schematic shows the most common type of water brake, known as the "variable level" type. Water is added until the engine is held at a steady RPM against the load, with the water then kept at that level and replaced by constant draining and refilling (which is needed to carry away the heat created by absorbing the horsepower). The housing attempts to rotate in response to the torque produced, but are restrained by the scale or torque metering cell that measures the torque. ----------------------------------------------------------------------------------------------------- |

||||||||||||

| Q 4 e ) |

4 |

Question:Three masses 10 kg, 20 kg and 15 kg are attached at a point at radii of 20 cm, 25 cm and 15 cm respectively. If the angle between successive masses is 60° and 90°. Determine analytically the balancing mass to be attached at radius of 30 cm.Answer:

|

||||||||||||

| Q 4 f ) |

4 |

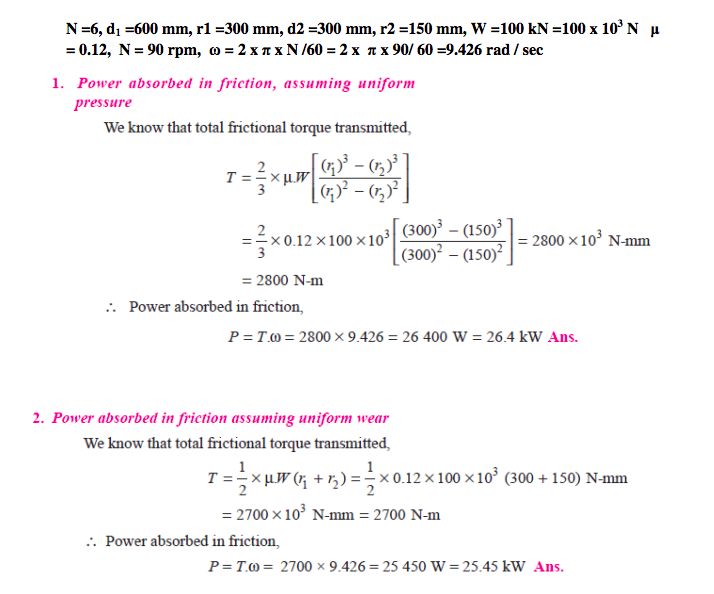

Question:A thrust shaft of a ship has 6 collar of 600 mm external diameter and 300 mm internal diameter. The total thrust from the propeller shaft is 100 kN. If the coefficient of friction is 0.12 and speed of engine 90 rpm. Find power absorbed in friction at the thrust block using uniform pressure intensity condition.Answer:

|

||||||||||||

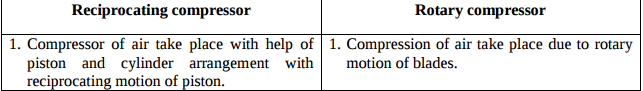

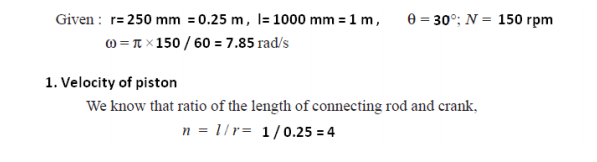

| Q 5 a ) |

8 |

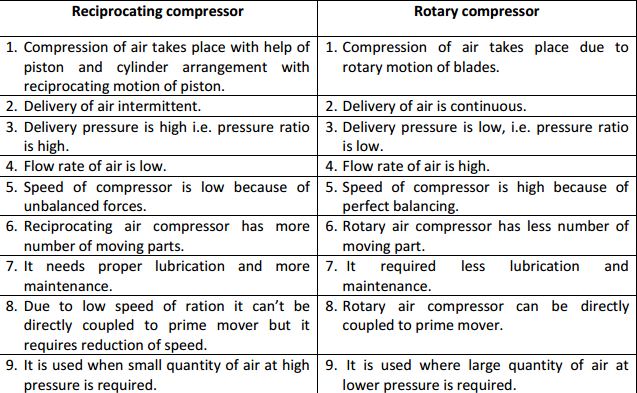

Question:Differentiate between reciprocating and rotary compressorsAnswer:

|

||||||||||||

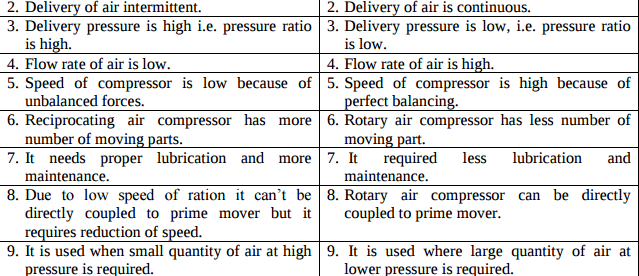

| Q 5 a ) |

8 |

Question:In reciprocating engine the crank is 250 mm long and connecting rod is 1000 mm long. The crank rotate at 150 rpm. Find velocity and acceleration of piston and angular velocity and angular acceleration of connecting rod when the crank makes an angle of 30° to IDC. Use analytical method.Answer: Solution of problem on Reciprocating Engine :

|

||||||||||||

| Q 5 b ) |

8 |

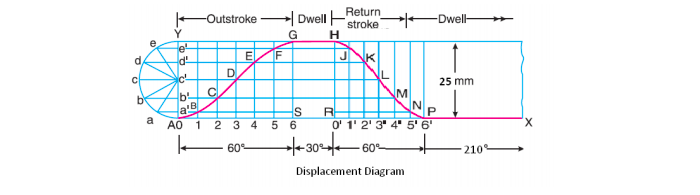

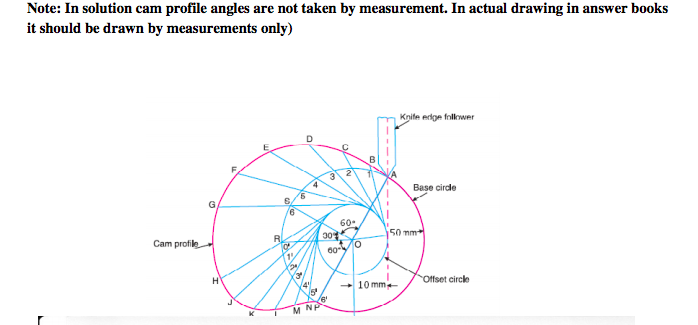

Question:Construct a cam profile with knife edge follower having an offset of 10 mm for the following data : Outstroke = 60° with SHM Dwell = 30° Return = 60° with uniform velocity and remaining is dwell period. Minimum radius of cam = 50 mm Lift of follower = 25 mm Consider the rotation of cam in clockwise direction.Answer:

|

||||||||||||

| Q 5 b ) |

8 |

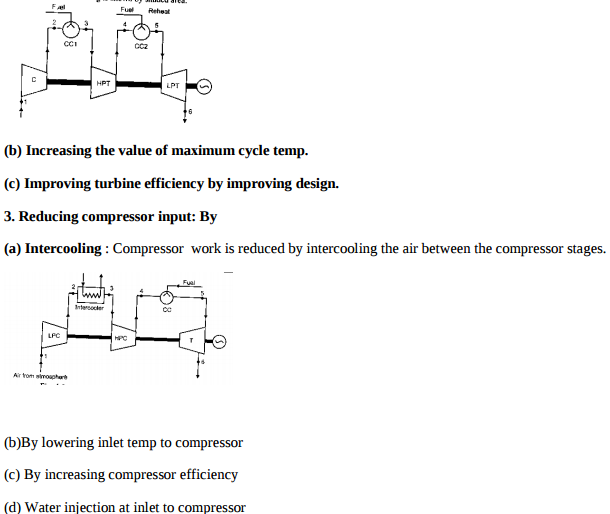

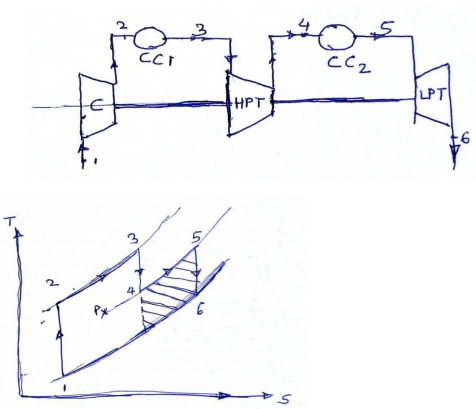

Question:Explain intercooling and reheating in gas turbine with the help of T-S diagram.Answer:

ii) Gas turbine with reheatingCC – Combustion Chamber C – Compressor

By reheating or adding heat to exhaust gases after have passed through a part of the rows of turbine balding (or stages), a further increase in work done obtained. In reheating, the gas temperature which has dropped due to expansion is brought back to approximately the initial temperature for expansion in next stage. Since the working fluid contains about 85% of air, additional fuel can be burnt by injecting it into the gases without any additional air supply. The reheat cycle can be shown as 1 – 2 – 3 – 4 – 5 – 6. The combustion gases from combustion chamber CC1 at temperature T3 is partially expanded in the HP turbine from P2 to intermediate pressure Px. After this, it is them passed through combustion chamber CC2 where it is reheated at constant pressure Px so that the temperature of gas is raised from T4 to T5. After this gas is expanded in second stage of turbine reheating is shown by shaded area

----------------------------------------------------------------------------------------------------- |

||||||||||||

| Q 5 c ) |

8 |

Question:A belt is required to transmit 10 kW from a motor running at 600 rpm. The belt is 12 mm thick and has a mass density 0.001 gm/mm3 . Safe stress in the belt is not to exceed 2.5 N/mm2 , diameter of the driving pulley is 250 mm whereas the speed of the driven pulley is 200 rpm. The two shafts are 1.25 m apart. The coefficient of friction is 0.25, determine (1) Angle of contact at driving pulley (2) The width of the beltAnswer:

|

||||||||||||

| Q 5 c ) |

8 |

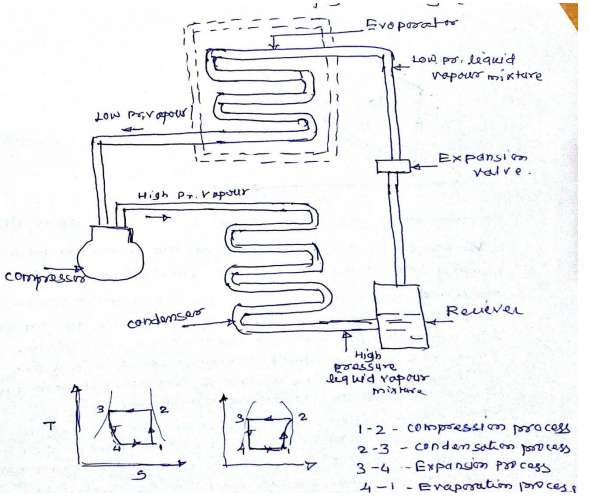

Question:Draw a neat sketch of vapour compression refrigeration cycle. Describe its workingAnswer:

Vapour compression refrigeration cycle Vapour compression refrigeration cycle consist of four different processes 1) Compression 2) Condensation 3) Expansion 4) Evaporation Components and its functions 1) Compressor – The low pressure & temperature refrigerant from evaporator is drawn into compressor. It is compressed to a high pressure & high temp. vapour refrigerant is discharged into condenser. 2) Condenser – High pressure & temperature vapour refrigerant is cooled and condensed by using air or water & form liquid vapour refrigerant. Heat is rejected 3) Expansion valve – to control flow of refrigerant and reducing it pressure and temperature 4) Evaporator – liquid vapour refrigerant at low pressure and low temperature is evaporated by absorbing heat from system or substance and change into vapour refrigerant. ----------------------------------------------------------------------------------------------------- |

||||||||||||

| Q 6 a ) |

8 |

Question:State the strength equations of double parallel fillet weld and single transverse fillet weld with neat sketches.Answer: