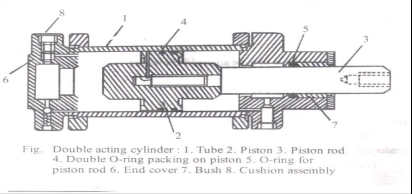

What are actuators ? Draw a double acting cylinder.

Actuator - Actuators are those components of hydraulic / pneumatic system, which produces mechanical work output. They develop force and displacement, which is required to perform any specific task. An actuator is used to convert the energy of the fluid back into mechanical power.