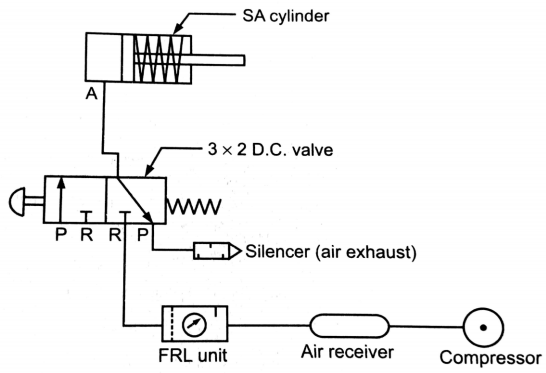

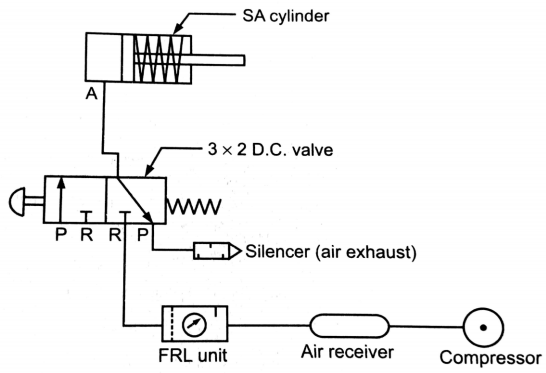

Explain pneumatic circuit for speed control of single acting cylinder with neat sketch.

1 Industrial: Plastic processing machineries, steel making and primary metal extraction applications, automated production lines, machine tool industries, paper industries, loaders, crushes, textile machineries, R & D equipment and robotic systems etc. 2 Mobile hydraulics: Tractors, irrigation system, earthmoving equipment, material handling equipment, commercial vehicles, tunnel boring equipment, rail equipment, building and

Castrol-Shell-Indian oil

Pneumatic system Advantages Disadvantages are given in details below.

Air being freely and easily available everywhere there is no scarcity of the source. Just need some filtration for its use in the pneumatic system. As compared to the Hydraulic oil it is very cheap.

Time delay valve function : In certain applications like machining or press operation it is necessary that certain operation be delayed by some fraction even after pressing valve. This objective is achieved by Time delay valve.

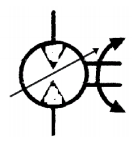

In all pneumatic power tools like screw drivers, angle grinders, straight grinders. To rotate conveyor belts in food industry. Power device in printing press machine Agitators and mixers Vibrators. symbol for variable speed bidirectional air motor

Merits: 1)Well equipped with quick connect or disconnect end fitting 2)Can be manufactured in long lengths 3)Capable of withstanding to very high pressures. 4)They can absorb very heavy shocks tha rigid tubes. Demerits: 1) Very poor in abrasion resistance 2) Poor in resisting whether condition. 3) Initial cost is very high 4) They can damage due to incompatible oil

FRL Unit: It is service unit used in Pneumatic system which is combination of three devices named as Filter, Regulator and Lubricator. Function of FRL unit Filter (F) – 1) To remove the micron and sub-micron particles present in the entering air of compressor. It is Used to separate out contaminants like dust, dirt p[articles from the compressed air Regulator (R) – In pneumatic system the pressure of compressed air may not stable due to possibility of line fluctuation. Hence there is a need to maintain and regulate the air pressure. This function is performing by regulator.