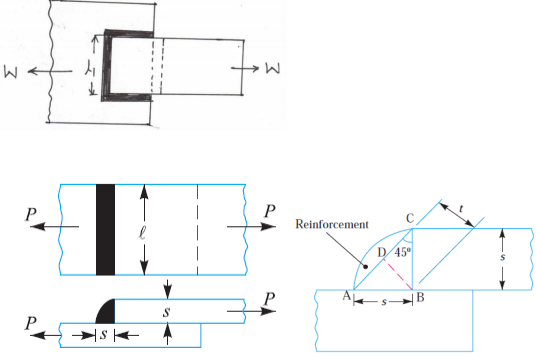

Explain the construction of 4/2 poppet valve with neat sketch & symbol.

4/2 puppet valve Figure shows a cross sectional schematic view of a poppet type 4/2 direction control valve. Inside the valve housing, a number of bores are engraved and interconnected through number of valve elements. The ports ‘P’, ‘R’, ‘A’, and ‘B’ shown in the diagram are designated as ‘Ppressure port, ‘A’ and ‘B’ – cylinder port and ‘R’ – exhaust port. In the position shown in the sketch, it is found that ‘P’ connects to ‘A’ and ‘B’ to ‘R’, When the elements are actuated by means of the push button, they are unseat and ‘P’ connects to ‘B’ and ‘A’ to ‘R’.