Q.1. Classify hydraulic pumps.

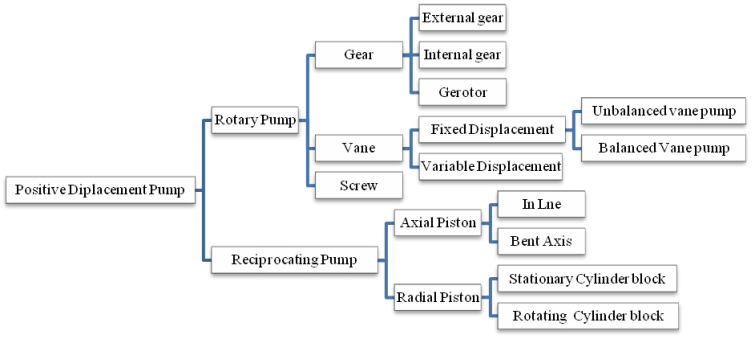

Ans : Hydraulic pumps are designed and manufactured over a wide range of constructions and capacities, to suit the particular requirement of the application. Pumps in general are classified on following basis,

1) Classifications based on principle

of operation

Hydrostatic type pumps (Positive displacement).

Hydrodynamic type pumps (Non - Positive displacement type).

2) Classification based on

displacement

Constant displacement pumps.Variable displacement pumps.

3) Classification based on

Constructions

1) Gear type Pumps - External gear pump.

- Internal gear pump.

2) Vane type pumps - Constant displacement vane pump.

- Variable displacement vane pump.

3) Piston type pumps - Radial piston pump.

-

Axial piston pump. (Swash plate & bent axis)

-Screw type pumps.

-

Ball piston type pumps.

Q.2. State the function of pump in a hydraulic system.

Ans : Hydraulic pump is the heart of a

hydraulic system. Its function is to convert mechanical energy into

hydraulic energy by pushing the hydraulic fluid into the system.

Pump is an energy conversion element, which receives energy from the prime mover (generally an electric motor or engine), and imparts it to fluid. Most of hydraulic pumps

receive fluid form reservoir and pump it to loaded actuator to perform work.

It is worth noting that a pump dose not create the pressure, but load on the fluid (resistance to its free motion) creates the pressure.

Q.3. State the importance of pump used in hydraulic system

Ans :

1. They convert mechanical energy into hydraulic energy.

2. The Volumetric efficiency of pump is relatively high

3.They have high performance characteristics under varying speed and pressure requirements

4.Pumps used to generate high pressure in hydraulic system

- Log in to post comments