Q.1. What are actuators ? Draw a double acting cylinder.

Ans: Actuator - Actuators are those components of hydraulic / pneumatic system, which produces mechanical work output. They develop force and displacement, which is required to perform any specific task. An actuator is used to convert the energy of the fluid back into mechanical power.

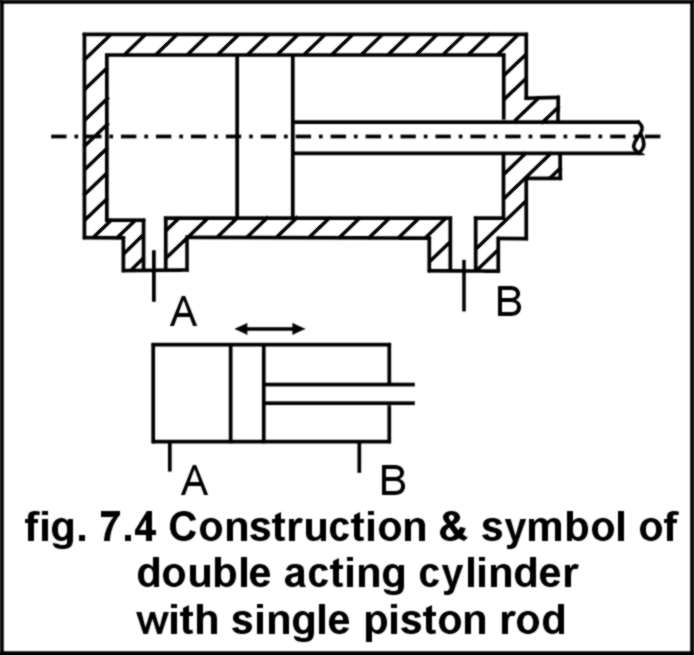

A double acting cylinder with single piston rod is shown in figure. The fluid pressure can be exerted on both sides of piston whenever required. This is the most common type of design and available in various sizes.

Here there are two different piston areas on both sides of piston, due to presence of piston rod on one side. Due to differential area, the retraction stroke is faster than extension stroke; as well, force obtained in extension stroke is more than that of in retraction stroke.

Q.2. Explain with sketch Double acting cylinder with double piston rod

Certain applications such as feeding of machine table in machine tools, demands motion to be transmitted on both sides of cylinder. In such application double acting, double rod cylinders are

They have piston rods extending out from both ends of cylinder. Since the annular area is same on both sides, it has forward and reverse stroke of same speed and same force.

Q.3. Explain with sketch Telescopic cylinder

OR

Q.18. One application needs a single acting cylinder capable of giving longer stroke strength. However the space available to fit in that cylinder in retracted condition is comparatively less. Suggest the type of actuator to be used in such condition with justification. Explain its working with sketch

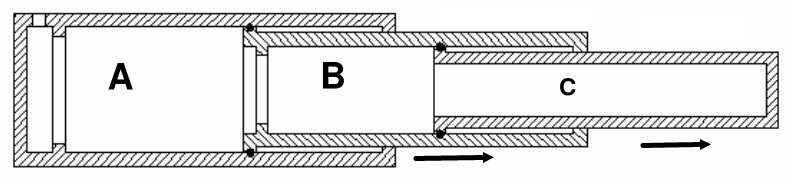

Ans :A telescopic cylinder is one which takes less space but has very long stroke.

As shown in figure above it has three or more parts which fit in each other. First part has biggest diameter and has main oil inlet connection. It is shown by part A in the diagram. Second part is bit of smaller diameter than it and is shown by part B. The last part has smallest cylinder diameter and is denoted by letter C. As the oil is supplied to cylinder first part B and C together extend out. Then as further oil is supplied the part c starts protruding out from B. Thus resulting in final extension. The return in this case occurs by the load itself, as generally such cylinder is applied with vertical loads.

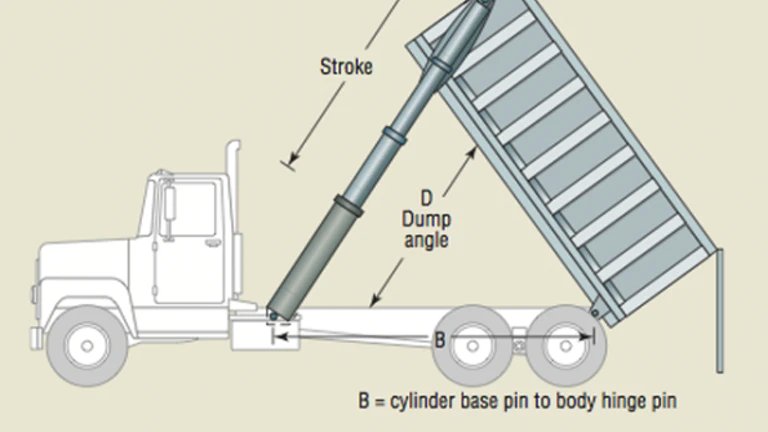

The most common application of this cylinder is found in dumpers we used to see on roads also as an attachment to the tractor trolleys.

(Such an application is shown below for Understanding purpose)

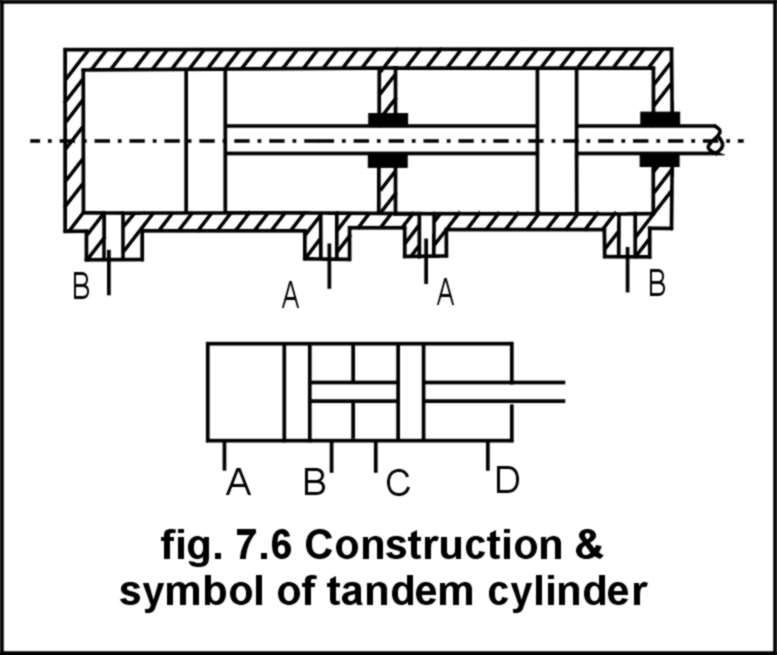

Q.4. What is Tandem cylinder? What is its beneficial property? Explain with sketch and draw its symbol.

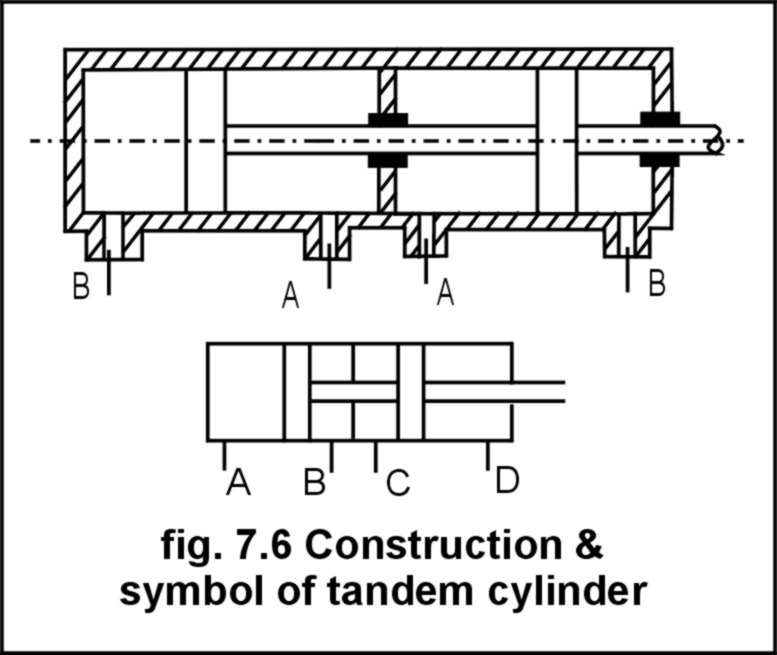

A Tandem cylinder is the combination of two or more cylinders working in tandem i.e. coupled mechanically to each other. Each cylinder has its own inlet outlet ports, but can not operate independent of other cylinder.

The advantage of tandeming the cylinder lies in forces addition, greater forces can be obtained at same pressure without increasing the piston sizes, but increasing the area on which the pressure acts by coupling the two or more cylinders. This finds application especially where high force requirement with limited space is required. Total

force obtained at piston rod,

F= P x A + P (A-a)

Where, P = Pressure in the cylinder , A = Cross sectional area of piston a = Cross sectional area of piston rod

Symbol of Tandem Cylinder

Q. 5.Enlist various types of air motors? Explain with sketch any one of them

Ans :

Various Types of Air Motors

1. Vane Motor

2. Ge-rotor Motor

3. Turbine Motor

4. Piston Motor

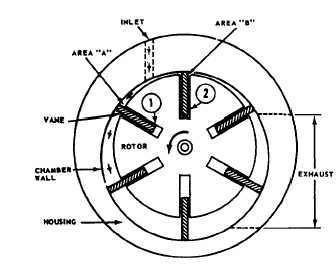

Construction: It consists of simple Vane rotor which is having slots in which vanes (flat piece of steel) slides freely. The rotor is eccentrically located inside the stator housing.

Working: When pressurized air comes in through inlet port, the pressure of air distributes equal in all directions. Since vane is sliding freely in slots of rotator, the vane comes in to way of pressurized air and air pushes the vanes so that rotor starts rotating with speed. The used low pressure air is exhausted through exhaust port. This is unidirectional motor. Since vanes are freely sliding in slots, there is possibility of leakage of air. With the help of these motors we can achieve the speeds up to 25000 r.p.m.

Q.6.Enlist advantages and limitations of air motor over electric motor and hydraulic motor.

Advantages of air motor :

1) Low power to weight ratio : Air motor develops more kW/Kg of weight as compared to others hence, finds applications where lightness and compactness is required.

2) Shock and explosion proof : Air motors are inherently shock and explosion proof. This characteristic is increasing their application in the explosion prone areas, where using an electric motor needs very special and costlier construction.

3) No overheating : The air motors can be overloaded or stalled without hawing. On the other hand the harder an air motor works, the cooler it runs, because air creates a cooling effect while it expands in motor.

4) Faster acceleration and deceleration : Due to their low inertia it can accelerate and decelerate faster. As compared to the electrical motor (which has heavy shaft, windings etc. on it) the air motor does not have such loads on the shaft.

5) Clean in operation: As compared to hydraulic motor, the leaks from motor become quite messy and can result in damage to material, which is being processed. This is not the case with air motors, hence air motors are found widely applicable in food processing industry. As well, the at motor is comparatively easy to maintain due to cleanliness.

Limitation of Air Motor :

1) Noisy operation The air exhausting from the motor creates unpleasant sound, unless it is absorbed by use of mufflers.

2) Non precision motion In applications where high precision motion is required air motors are not suitable due to compressibility of air.

- Log in to post comments