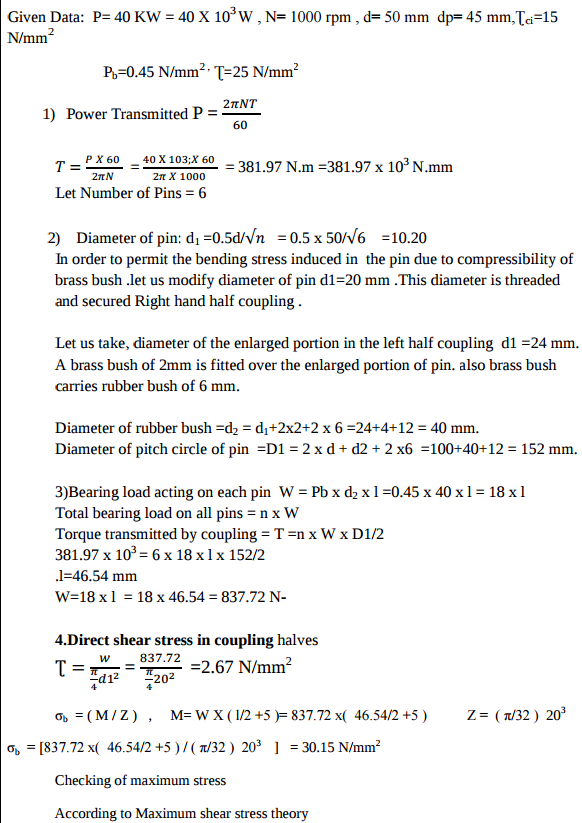

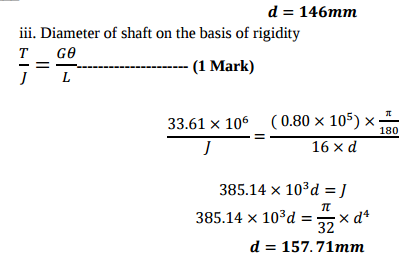

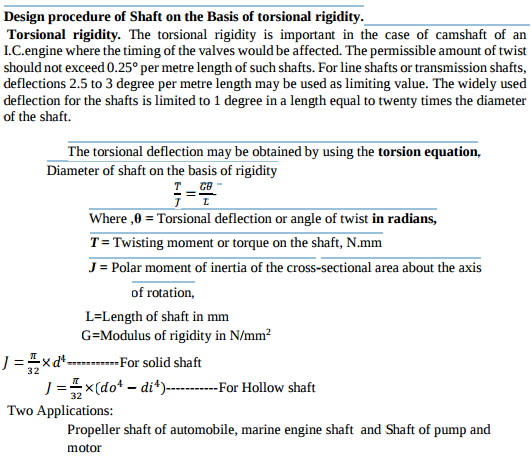

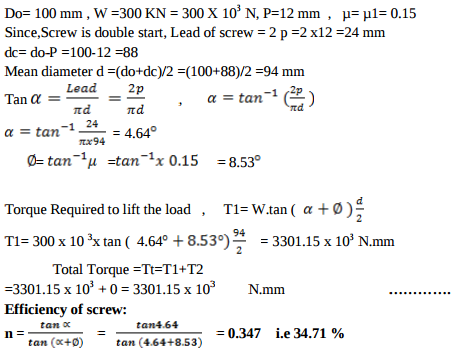

The shaft running at 125 r.p.m. transmits 440 kW. Find the diameter of shaft (d) if allowable shear stress in shaft material is 55 N/mm2 and the angle of twist must not be more than 1 on a length of 16(d). The modulus of rigidity G = 0.80 105 N/mm