Explain any one method to improve thermal efficiency of gas............

+

+

+

+

![]()

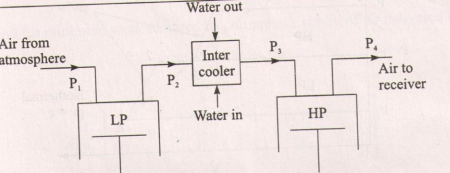

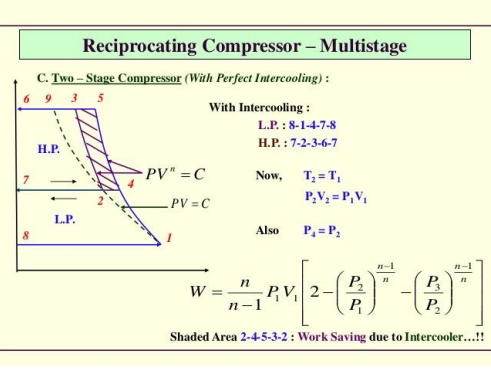

Multi-stage air compressors feature many benefits and so, they are mostly used in the market. Some of those features are given below 1. Higher air pressures are achievable by multi-staging (about 175 PSI against 120 PSI in single stage) 2. It requires less power for running 3. Light weight cylinders can are used 4. Leakages are less 5. Overall discharge temperatures are lower 6. Intercooler increases the efficiency of unit 7. It has a greater durability 8. Many multi-stage air compressors have the crankcase cast separate from the pump cylinders, which makes it easier to repair. 9.

The main components of turbo-prop engine are a propeller, gear reduction unit, a compressor, a combustor, gas turbine and the nozzles. In this engine 80 to 90% of the total propulsive thrust is generated by the gas turbine and the remainder is developed by the expansion of the gases in nozzles. Due to this the power generated in the gas turbine is used for driving the compressor and the propeller, while in case of turbojet engines the turbine power is only used to drive the compressor and the auxiliaries.

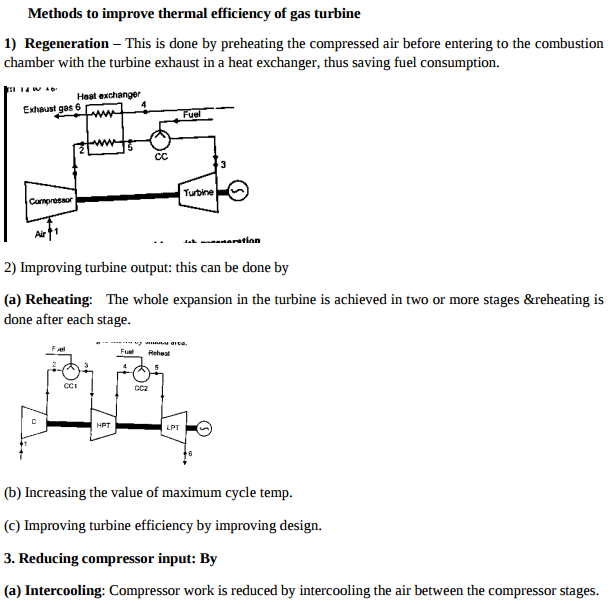

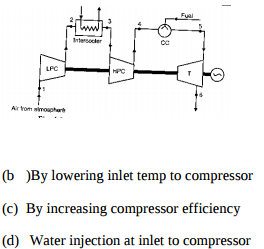

Intercooling : In perfect intercooling the temperature of air after passing out of intercooler is same as that of the temperature of air before compression of LP cylinder.

Working of Simple Vapor absorption system: A Simple Vapor absorption system consists of evaporator, absorber, generator, condenser, expansion valve, pump & reducing valve. In this system ammonia is used as refrigerant and solution is used is aqua ammonia. Strong solution of aqua ammonia contains as much as ammonia as it can and weak solution contains less ammonia. The compressor of vapor compressor system is replaced by an absorber, generator, reducing valve and pump. The heat flow in the system at generator, and work is supplied to pump.

(1) Detergents – To keep engine parts, such as piston and piston rings, clean & free from deposits. (2) Dispersants – To suspend & disperse material that could form varnishes, sludge etc that clog the engine. (3) Anti – wear – To give added strength & prevent wear of heavily loaded surfaces such as crank shaft rods & main bearings. (4) Corrosion inhibitors – To fight the rust wear caused by acids moisture. Protect vital steel & iron parts from rust & corrosion.