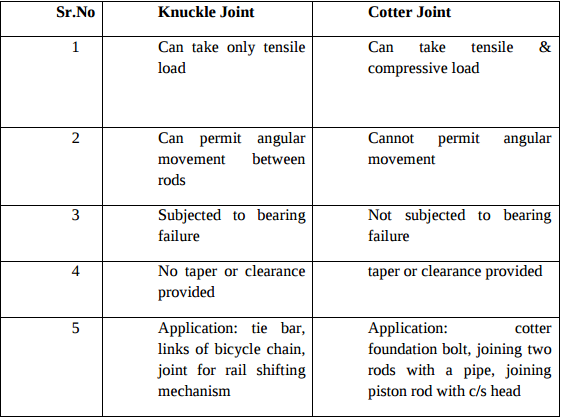

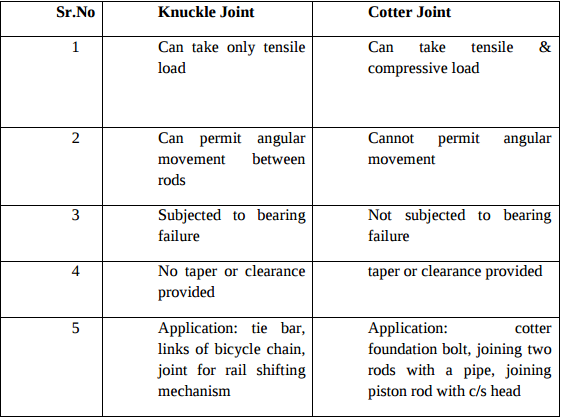

Differentiate between Knuckle joint and Cotter joint................

1. Recognition of need. First of all, make a complete statement of the problem, indicating the need, aim or purpose for which the machine is to be designed. 2. Synthesis (Mechanisms). Select the possible mechanism or group of mechanisms which will give the desired motion. 3. Analysis of forces. Find the forces acting on each member of the machine and the energy transmitted by each member. 4. Material selection. Select the material best suited for each member of the machine. 5. Design of elements (Size and Stresses).

Application of bearings : …… i) Deep Groove Ball bearing : Electric Motor ii) Taper roller bearing : axle housing of automobile iii) Thrust collar bearing: Clutch of automobile iv) Needle roller bearing: Differential of automobile

Disadvantages of rolling bearing as compared to Journal Bearing: 1) Initial cost is very high 2) Noisy in normal operation. 3) Shock capacity is less. 4) Finite life due to failure by fatigue. 5) Dirt & metal chips can enter the bearing & may lead it to failure. 6) Occupies greater diametral space compared to journal bearing.

Bolt size will be M 30 or M32

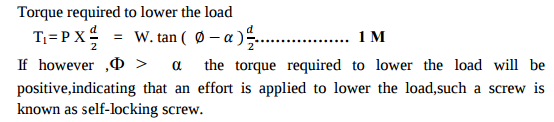

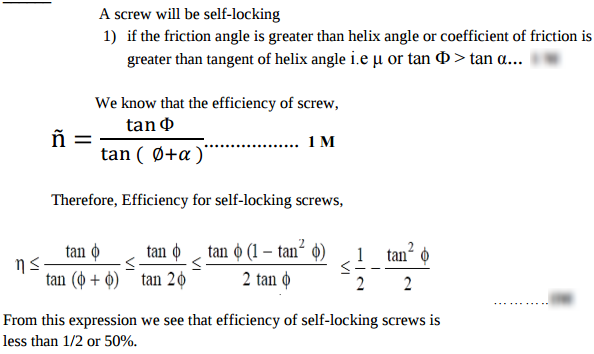

Square threads are the most commonly used thread form for the power screws. Following table gives you various thread forms and comparisons.

|

Screw Form |

Characteristic |

Application |

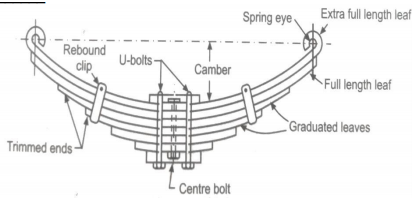

Sketch of Leaf Spring of semi elliptical Type ….Diagram+ Names :

1) The ball bearings have a far smaller contact area and thus have a lower frictional drag coefficient. 2) Due to less frictional drag means better response and less power consumption. 3) The turbo can spool up much faster, which reduces turbo-lag and offers a major performance advantage over journal bearing turbochargers at lower to mid turbocharger speeds. 4) The reduced contact area of the ball bearings means that it requires far less lubrication, allowing for lower oil pressure feeds. 5) The ball bearing more reliable. 6) Less expensive.