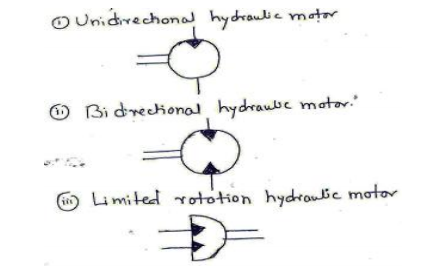

Draw symbol of any three types of Hydraulic motors.

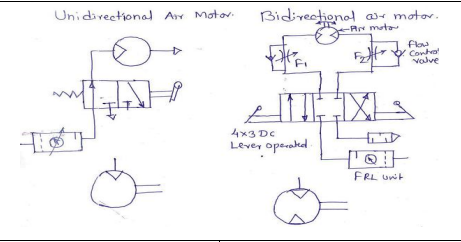

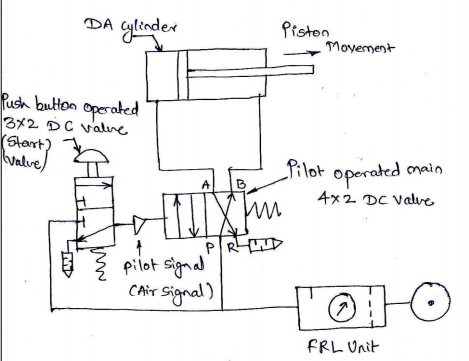

Operating or moving or allowing movement in one direction only. It runs in one direction only. It does not run in the other direction. Unidirectional motor can be operated by using 3/2 DC valve as shown in fig. Bidirectional air motor: Functioning or allowing movement in two usually opposite directions. It can runs in both direction. Bi-directional motor can be operated by using 4/3 DC valve as shown in fig

1. Relatively low accuracy: As pneumatic systems are powered by the force provided by compressed air, their operation is subject to the volume of the compressed air. As the volume of air may change when compressed or heated, the supply of air to the system may not be accurate, causing a decrease in the overall accuracy of the system. 2. Low loading: As the cylinders of pneumatic components are not very large, a pneumatic system cannot drive loads that are too heavy. 3. Processing required before use Compressed air must be processed before use to ensure the absence of water vapour or dust.

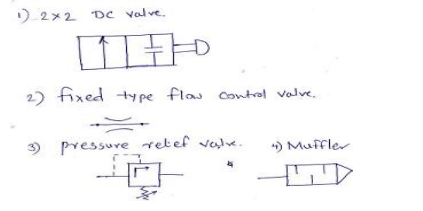

1. DC valves are used to release, stop or redirect the fluid that flows through it. 2. DCV is used to control the direction of fluid flow in any hydraulic system and changing the position of internal movable parts. 3. To start, stop, accelerate, decelerate and change the direction of motion of a hydraulic actuator. 4. To permit the free flow from the pump to the reservoir at low pressure when the pump’s delivery is not needed into the system. 5. To vent the relief valve by either electrical or mechanical control. 6.

FRL unit means Filter Regulator and Lubricator Unit Function of FRL unit Filter (F) – 1) To remove the micron and sub-micron particles present in the entering air of compressor 2) Used to separate out contaminants like dust, dirt particles from the compressed air Regulator (R)–In pneumatic system the pressure of compressed air may not stable due to possibility of line fluctuation. Hence there is a need to maintain and regulate the air pressure. This function is performed by regulator. Lubricator (L) – Sliding components like spool, a pneumatic cylinder has sliding motion between parts.

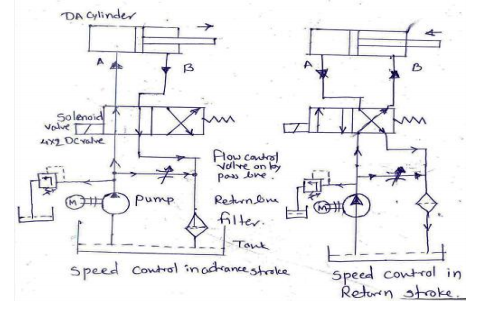

Principle of regenerative circuit is recovering the energy available with returning oil by using regeneration technique. The concept of re-generative circuit is explained from following figure. Consider the double acting cylinder. Pressurized oil from pump is admitting in cylinder cavity through port (A). Due to pressure force piston is moving from right to left. During this movement, the oil present on piston rod side of piston starts coming out through port (B). This oil will return to the oil reservoir via DC valve.