List the methods to reduce the slip in belt and pulley.

Methods to reduce the slip in belt and pulley:

1. Vertical belt drive should be avoided.

2. In horizontal belt drive the upper side should be kept as loose side.

Methods to reduce the slip in belt and pulley:

1. Vertical belt drive should be avoided.

2. In horizontal belt drive the upper side should be kept as loose side.

Law of Gearing: The law of gearing states that the angular velocity ratio of all gears of a meshed gear system must remain constant also the common normal at the point of contact must pass through the pitch point.

Self energizing & Self Locking brake

Rn x X = PL + μaRn

Rn = Normal reaction, P = Applied force, L = lever length

X = Distance of block from hinge, μ= coefficient of friction, a = distance of drum from hinge

In the above equation when frictional force adds to the breaking torque. In other words, the frictional torque and braking torque are in the same direction its a self locking brake.

In the above equation when X < μa, P becomes negative

Limitations of a shoe brake :

1. Heavy side thrust causes bending of the shaft.

2. More wear & tear as the contact surface is large.

Types of followers :

The followers may be classified as discussed below:

1. According to the surface in contact.

(a)Knife edge follower. When the contacting end of the follower has a sharp knife edge, it is called a knife edge follower.

(b) Roller follower. When the contacting end of the follower is a roller, it is called a roller follower.

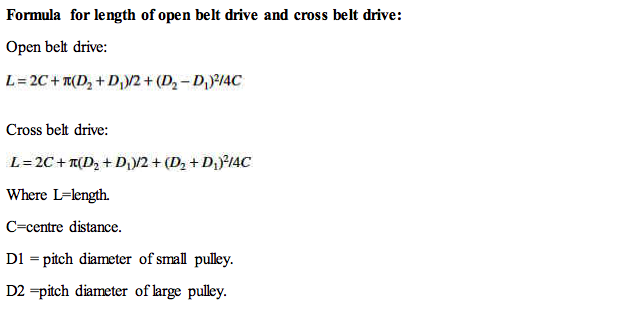

Ans.: Given data; N1 = 80 rpm. N2 =150 rpm. D1= 600 mm. S = 4 % To find; D2 =?;

(i) Case I: Taking t = 5 mm. Velocity ratio, (V.R.) N2/N1 = (D1 + t)/ (D2 + t)

150/80 = (600 + 5)/ (D2 + 5)

Therefore, diameter of driven pulley D2 = 317.66 mm ~ 318mm

(ii) Case II: Assuming for belt thickness 5 mm and total slip of 4%. Velocity ratio, (V.R.) N2/N1 = {(D1 + t)/ (D2 + t)} × {1- (S/100)}

150/80 = {(600 + 5) / (D2 + 5)} × {1- (4/100)

Therefore, diameter of driven pulley D2 = 304.76 mm ~ 305 mm