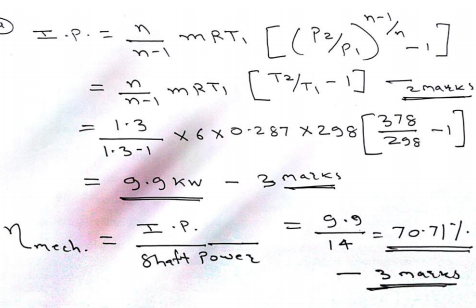

Reciprocating air compressor draws 6 kg of air per minute at 25°C. It compresses the air....

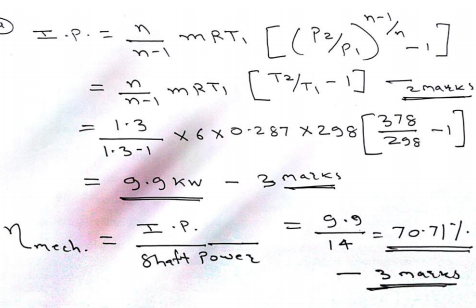

Regenerative method to improve thermal efficiency in gas turbines : The exhaust gases a lot of heat as their temperature is far above the ambient temperature . The heat of exhaust gases can be used to heat the air coming from the compressor thus reducing the mass of the fuel supplied in the combustion chamber as shown in the figure. This method is called regenerative method.

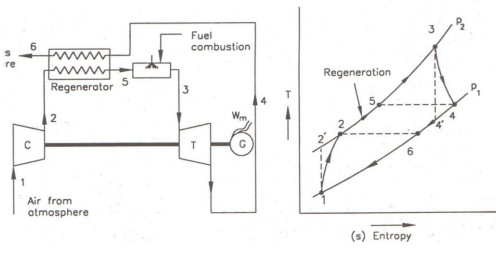

Fuel injection pump : Fuel injection pump is used widely for the supply of fuel under high pressure in diesel engines

Classification of gas turbine on the basis of

a. Cycle of operation 1. Open cycle 2. Closed cycle

b. Thermodynamic cycle 1. Brayton or Joules cycle 2. Atkinson cycle 3. Erricsson cycle

c. Application 1. For supercharging of IC engine 2. For locomotive propulsion 3. For ship propulsion 4. Industrial application 5. Air craft engines 6. Electric power generation

d. Combustion process 1. Continuous combustion 2. Explosion combustion

Classification of Air compressors:

1. According to principle: a) Reciprocating air compressors b) Rotary air compressors 2. According to the capacity a. Low capacity air compressors b. Medium capacity air compressors c. High capacity air compressors 3. According to pressure limits a. Low pressure air compressors b. Medium pressure air compressors c. High pressure air compressors 4. According to method of connection a. Direct drive air compressors b. Belt drive air compressors c. Chain drive air compressors

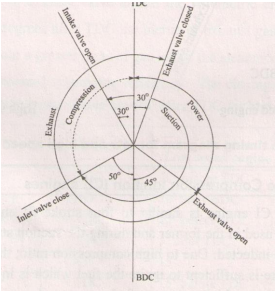

Valve timing diagram of four stroke diesel engine

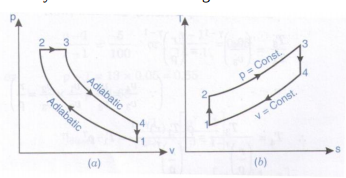

Diesel Cycle on P-V and T-S diagram :

Processes : 1-2 : Isentropic compression 2-3 : Heat addition at constant pressure 3-3 Isentropic expansion 4-1 Heat rejection at constant volume

1) Adaptor – To connect two pipes of different diameters. 2) Coupling- To connect two pipes of same diameters. 3) Tee- To connect two pipes with one pipe. 4) Cross- To connect two pipes in crosswise. 5) Elbow- To divert the flow between two pipes at right angle. 6) Hex nipple- To connect two pipes internally with the help of hexagonal nut. 7) 450 Elbow- To divert the flow between two pipes at 450 angle. 8) Reducer- To connect two pipes of different diameters and it will increase or reduce the pressure of flow

1 Industrial: Plastic processing machineries, steel making and primary metal extraction applications, automated production lines, machine tool industries, paper industries, loaders, crushes, textile machineries, R & D equipment and robotic systems etc. 2 Mobile hydraulics: Tractors, irrigation system, earthmoving equipment, material handling equipment, commercial vehicles, tunnel boring equipment, rail equipment, building and