Enlist the hydraulic oil manufacturer’s in India...........

Castrol-Shell-Indian oil

Castrol-Shell-Indian oil

Pneumatic system Advantages Disadvantages are given in details below.

Air being freely and easily available everywhere there is no scarcity of the source. Just need some filtration for its use in the pneumatic system. As compared to the Hydraulic oil it is very cheap.

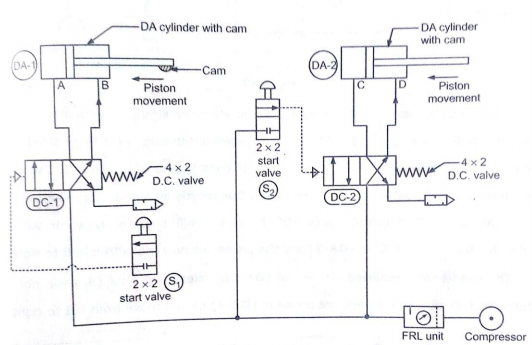

Figure 1 shows a symbol circuit of an impulse-valve controlled double acting pneumatic cylinder (A). The position of the impulse-valve (3), which is controlled by the start/stop-valve (1) and the end position valve (2), determines if the cylinder piston shall make a positive stroke and negative stroke. Positive piston stroke is initiated by manual activation of the start valve (1). Negative piston stroking takes place when valve (2) is activated by the cylinder rod at the position a1.

Answer: a pneumatic circuit for operation of two DA cylinders such that one operates after other using travel dependant sequencing as shown in fig.

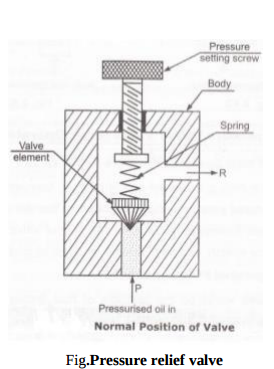

Pressure-relief valve.Pressure-reducing valve. Unloading valve Counterbalance valve Pressure-sequence valve Brake valve.

Counterbalance valves are commonly used to counterbalance a weight or external force or counteract a weight such as a platen or a press and keep it from freefalling.Figure1.16 illustrates the use of a counterbalance or back-pressure valve to keep a vertically mounted cylinder in the upward position while the pump idles, that is, when the DCV is in its center position. During the downward movement of the cylinder, the counterbalance valve is set to open at slightly above the pressure required to hold the piston up (a check valve does not permit flow in this direction).

Time delay valve function : In certain applications like machining or press operation it is necessary that certain operation be delayed by some fraction even after pressing valve. This objective is achieved by Time delay valve.