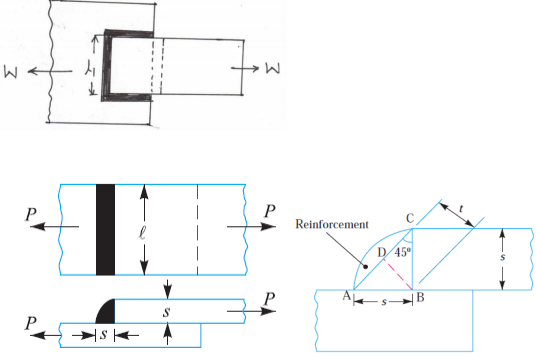

Explain any two mounting methods of cylinder. ................

1) Centreline mounting Centreline mounts are used to take care of thrust that can occur linearly or along a centreline with the cylinder. Proper alignment is essential to prevent compound stresses that may cause excessive friction and bending, as piston extends. Additional holding strength may be essential with long stroke cylinders. 2) Foot mounting It consists of mounting the cylinder with the help of side end lungs or side covers. These mountings are used where cylinders are to be mounted on to surface parallel to the axis of cylinder