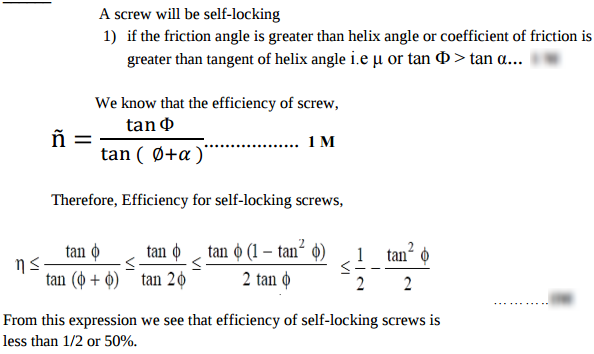

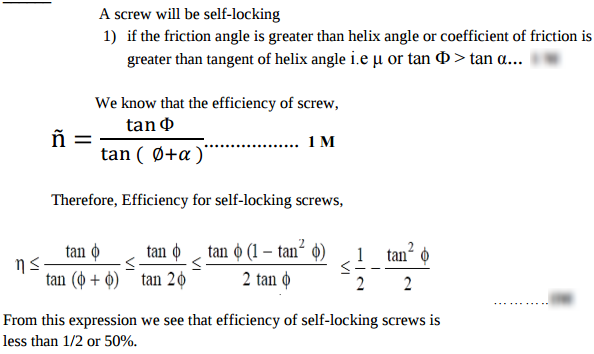

Show that the efficiency of self locking screw is less than 50%

1) The power to be transmitted 2) The velocity ration or speed of gear drive. 3) The central distance between the two shafts 4) Input speed of the driving gear. 5) Wear characteristics of the gear tooth for a long satisfactory life. 6) The use of space & material should be economical. 7) Efficiency & speed ratio 8) Cost

1) The shape should not be like blocks but various forms like sculpture, streamlined, aerodynamic, taper should be used. 2) The component should be symmetrical at lean about one axis. 3)proper shape of a product help to make the product more attractive. 4) The shape of the product should be regular, even & proportionate Regarding Colour: ……….Any 2 pt : 1 M Each 1) The colour and shape of component should be such that in should attract appeal and impress customer. 2) The colour should match with conventions, moods e.g.

1. The welded structures are usually lighter than riveted structures. This is due to the reason, that in welding, gussets or other connecting components are not used. 2. The welded joints provide maximum efficiency (may be 100%) which is not possible in case of riveted joints. 3. Alterations and additions can be easily made in the existing structures. 4. As the welded structure is smooth in appearance, therefore it looks pleasing. 5. In welded connections, the tension members are not weakened as in the case of riveted joints. 6. A welded joint has a great strength.

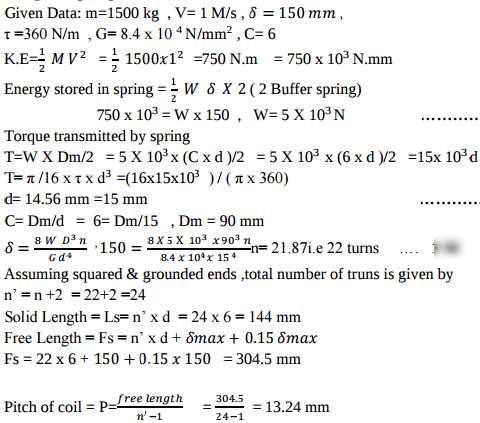

1) To cushion, absorb or control energy to external load : Car springs, Railway buffers 2) To store Energy : Watches Toys 3) To Measure forces : Spring Balances, Gauges ,Engines 4) To provide clamping force in Jigs & fixtures. 5) To apply forces as in brakes, clutches & spring loaded valve.

+

+

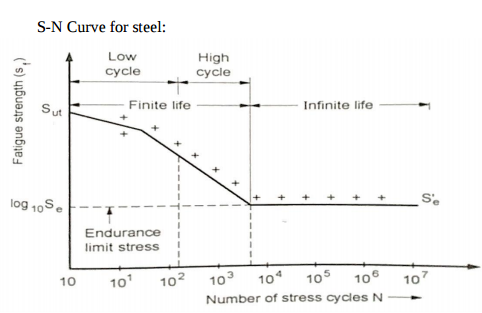

Endurance Limit: It is defined as maximum value of the completely reversed bending stress which a polished standard specimen can withstand without failure, for infinite number of cycles (usually 107 cycles).It is known as endurance or fatigue limit (ϭe).

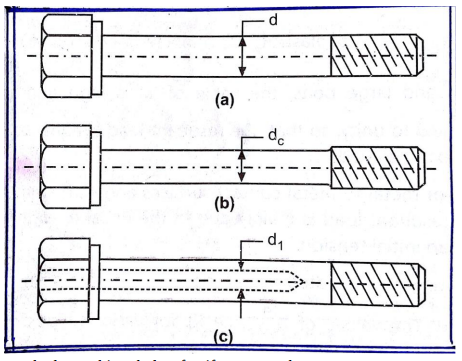

When an ordinary bolt of uniform diameter is subjected to shock load stress concentration across at the weakest part of the bolt i.e. threaded portion (as shown in figure a), it means that greater portion of energy will be absorbed at the region of threaded part and it may cause the failure of threaded portion