Explain the construction and working of doubled acting reciprocating compressor with neat sketch.

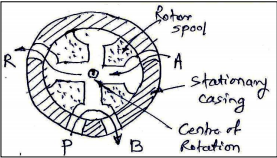

Double acting reciprocating air compressor is similar to double acting reciprocating pump. It is comprised of following parts: 1) Cylinder 2) Piston and piston rod and connecting rod. 3) Crank and crank case 4) Two suction valves and two delivery valves. 5) One inlet port and one outlet port It uses four bar mechanism. There are 4 valves (2 suction valves and 2 delivery valves) shown at A, B, C, D in figure. There are cooling fans similar to single acting compressors. The crank rotates on electric motor/engine/turbine.