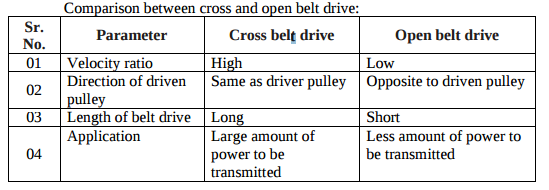

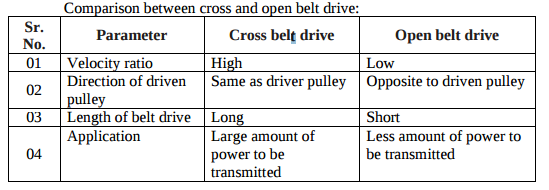

Compare cross belt drive and open belt drive on the basis of: (i) Velocity ratio. (ii) Direction of driven pulley. (iii) Length of belt drives (iv) Application.

(i) Uniform pressure theory:

When the mating component in clutch, bearing are new, then the contact between

surfaces may be good over the whole surface.

It means that the pressure over the rubbing surfaces is uniform distributed.

This condition is not valid for old clutches, bearings because mating surfaces may

have uneven friction.

The condition assumes that intensity of pressure is same.

P = W/A =Constant; where, W= load, A= area

(ii) Uniform wear theory in clutches and bearings:

Inversions of double slider crank chain:

i.Scotch Yoke mechanism.

ii.Oldham’s coupling.

iii. Elliptical trammel.

Stability of governor :

A governor is said to be stable when for every speed within the working range there is a definite configuration i.e. there is only one radius of rotation of the governor balls at which the governor is in equilibrium. For a stable governor, if the equilibrium speed increases, the radius of governor balls must also increase.

Hunting of governor :

A flywheel controls the speed variations caused by the fluctuation of the engine turning moment during each cycle of operation.

A flywheel used in machines serves as a reservoir, which stores energy during the period when the supply of energy is more than the requirement, and releases it during the period when the requirement of energy is more than the supply.

Advantages -1. The V-belt drive gives compactness due to the small distance between the centres of pulleys.

2. The drive is positive, because the slip between the belt and the pulley groove is negligible.

3. Since the V-belts are made endless and there is no joint trouble, therefore the drive is smooth.

4. It provides longer life of 3 to 5 years.

5. It can be easily installed and removed.

6. The operation of the belt and pulley is quiet.

7. The belts have the ability to cushion the shock when machines are started.

Slip : When the frictional grip becomes insufficient. This may cause some forward motion of the driver without carrying the belt with it. This may also cause some forward motion of the belt without carrying the driven pulley with it. This is called slip of the belt and is generally expressed as a percentage. Creep : When the belt passes from the slack side to the tight side, a certain portion of the belt extends and it contracts again when the belt passes from the tight side to slack side.

The follower during its travel may have one of the following motions.

1. Uniform velocity,

2. Simple harmonic motion,

3. Uniform acceleration and retardation,

4. Cycloidal motion.

1. Mechanism : When one of the links of a kinematic chain is fixed, the chain is known as mechanism.

2. Inversion of mechanism The method of obtaining different mechanisms by fixing different links in a kinematic chain, is known as inversion of the mechanism. So we can obtain as many mechanisms as the number of links in a kinematic chain by fixing, in turn, different links in a kinematic chain.

The high speed of engines and other machines is a common phenomenon now-a-days. It

is, therefore, very essential that all the rotating and reciprocating parts should be completely

balanced as far as possible. If these parts are not properly balanced, the dynamic forces are set

up. These forces not only increase the loads on bearings and stresses in the various members, but

also produce unpleasant and even dangerous vibrations. The balancing of unbalanced forces is