(i) State the steps involved in selection of a proper ball bearing from a manufacturer’s catalogue.

Steps Involved in selection of a proper ball bearing from Manufacture’s Cataloge

Steps Involved in selection of a proper ball bearing from Manufacture’s Cataloge

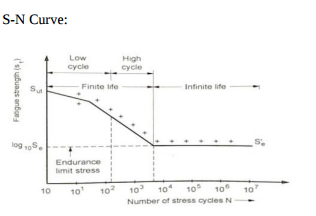

Endurance Limit: It is defined as maximum value of the completely reversed bending stress which a polished standard specimen can withstand without failure, for infinite number of cycles (usually 107 cycles).It is known as endurance or fatigue limit (ϭe). Need of Endurance Limit in Machine Design: Endurance limit is used to describe a property of materials: the amplitude (or range) of cyclic stress that can be applied to the material without causing fatigue failure.

Four Disadvantages of screwed joints: 1) Screwed joints are weaker than welded joint 2) Screwed joints weakens( due to holes) the parts that are to be joined. 3) Stress concentration in the threaded portion of screw makes them weak. 4) Locking arrangement is required in case of vibrations

Modes of Gear Failure: ANY 4 modes 1. Bending failure. Every gear tooth acts as a cantilever. If the total repetitive dynamic load acting on the gear tooth is greater than the beam strength of the gear tooth, then the gear tooth will fail in bending, 2. Pitting. It is the surface fatigue failure which occurs due to many repetition of Hertz contactstresses. 3. Scoring. The excessive heat is generated when there is an excessive surface pressure, high speed or supply of lubricant fails. 4. Abrasive wear.

Ergonomics consideration in the design of Lathe machine Any 4 1) The controls on lathe should be easily accessible and properly positioned. 2) the control operation should involve minimum motions. 3) Height of lathe should be match with worker for operation 4)Lathe machine should make less noise during operation. 5) force& power capacity required in turning the wheel as per operation or human being can apply normally. 6) should get required accuracy in operation.

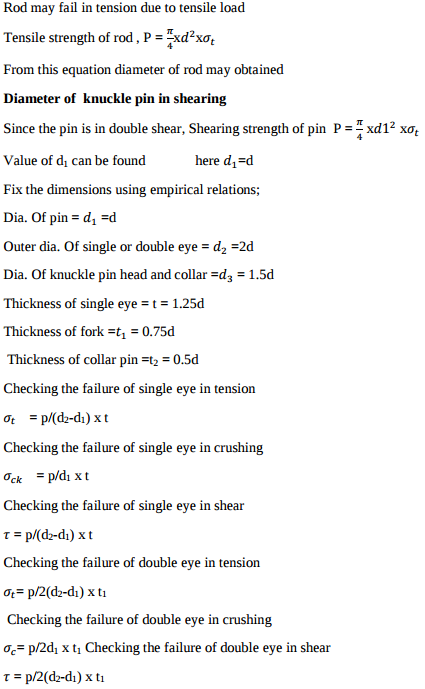

Design of Knuckle joint Failure of rod in tension