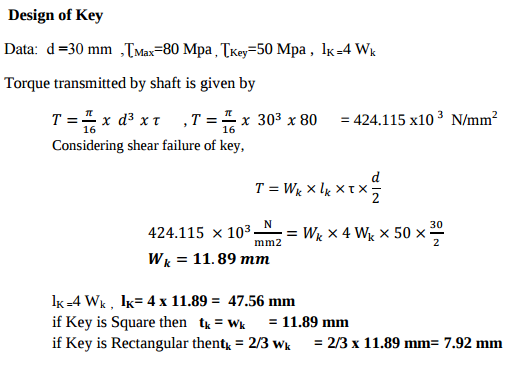

A shaft 30 mm. diameter is transmitting power.....................

Comparison of welded joints with screwed joint. 1) Welded Joint is rigid & permanent. Screwed joint is temporary. 2) Cost of welded assembly is lower than that of screwed joints. 3) Strength of welded structure is more than screwed joints. 4) For welding joints, highly skilled worker are required 5) Welded joints are tight & leak proof as compared to Screwed joints. 6) Welded joint is very difficult to inspect compared to other joints.