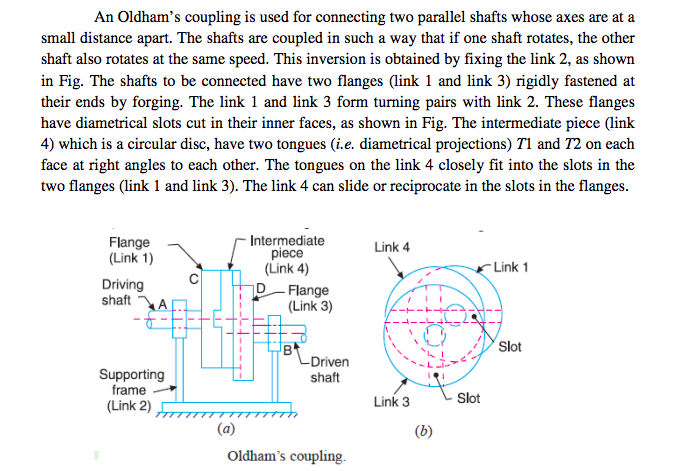

Explain with neat sketch working principle of Oldham’s coupling.

When the driving shaft A is rotated, the flange C (link 1) causes the intermediate piece (link 4) to rotate at the same angle through which the flange has rotated, and it further rotates the flange D (link 3) at the same angle and thus the shaft B rotates. Hence links 1, 3 and 4 have the same angular velocity at every instant. A little consideration will show that there is a sliding motion between the link 4 and each of the other links 1 and 3.